White Aluminum Checker Plate/Tread Plate Sheets for Stairs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

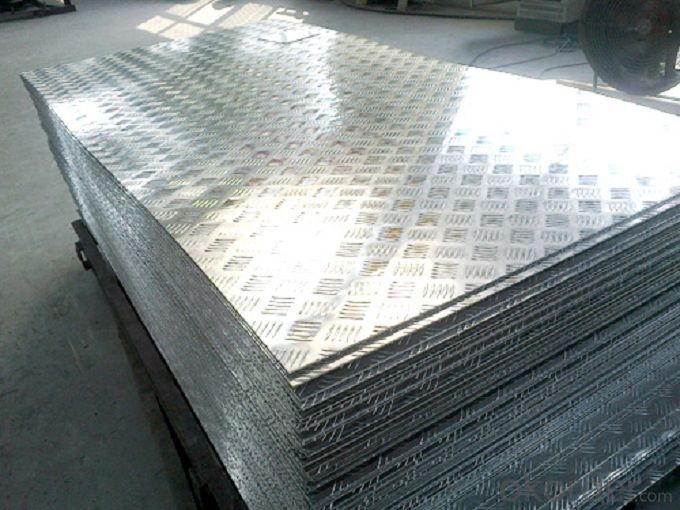

Aluminium Checker Plate/ Tread Plate Used for Stairs

l Product Description

1) Alloy: 1050. 1200, 1100, 3003, 5052, 5754

2) Temper: H111, H112, O, H14, H24, H32

3) Thickness: 0.8mm to 10mm

4) Width: 100mm to 2300mm, Length: up to 11 Meter,

5) Patterns: Two bar,three bar, Five bar and diamond plate

6) Use: Refrigeration floor, Truck floor, flooring, stairs, indoor and outdoor decoration

l Packaging & Delivery

Packaging detail: Standard seaworthy export packing, wooden pallets with plastic protection for sheets

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

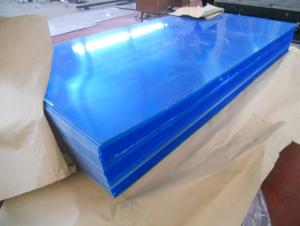

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: 1 ton of aluminium=______ tons of Alumina

- Aluminium is a reactive metal and it is hard to extract it from its ore, aluminium oxide (Al2O3). Direct reduction, with carbon for example, is not economically viable since aluminium oxide has a melting point of about 2000 °C. Therefore, it is extracted by electrolysis — the aluminium oxide is dissolved in molten cryolite and then reduced to the pure metal. By this process, the actual operational temperature of the reduction cells is around 950 to 980 °C. Cryolite was originally found as a mineral on Greenland, but has been replaced by a synthetic cryolite. Cryolite is a mixture of aluminium, sodium, and calcium fluorides: (Na3AlF6). The aluminium oxide (a white powder) is obtained by refining bauxite, which is red since it contains 30 to 40% iron oxide. This is done using the so-called Bayer process. Previously, the Deville process was the predominant refining technology. The electrolytic process replaced the W?hler process, which involved the reduction of anhydrous aluminium chloride with potassium. Both of the electrodes used in the electrolysis of aluminium oxide are carbon. Once the ore is in the molten state, its ions are free to move around. The reaction at the negative cathode is Al3+ + 3 e- → Al Here the aluminium ion is being reduced (electrons are added). The aluminium metal then sinks to the bottom and is tapped off. At the positive electrode (anode) oxygen gas is formed: 2 O2- → O2 + 4 e- This carbon anode is then oxidised by the oxygen. The anodes in a reduction must therefore be replaced regularly, since they are consumed in the process: O2 + C → CO2 So, as you can see, the exact tonnage required to produce 1 ton of aluminum is very sketchy at best...

- Q: Are aluminum sheets suitable for food processing equipment?

- Yes, aluminum sheets are suitable for food processing equipment. Aluminum is a widely used material in the food processing industry due to its excellent properties. It is corrosion-resistant, lightweight, and has good thermal conductivity, making it ideal for applications where hygiene and efficient heat transfer are crucial. Additionally, aluminum is non-toxic and does not react with food, ensuring that it does not affect the taste or quality of the processed products. Overall, aluminum sheets are a popular choice for food processing equipment as they meet the necessary safety and performance requirements.

- Q: What is the thickness of the aluminum sheets?

- Depending on the specific product or application, the thickness of the aluminum sheets may vary. Aluminum sheets come in a diverse range of thicknesses, typically varying from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm) or possibly even thicker. The suitable thickness will be determined by the specific requirements and intended usage of the aluminum sheet.

- Q: Can the aluminum sheets be used for manufacturing kitchen countertops?

- Yes, aluminum sheets can be used for manufacturing kitchen countertops. Aluminum is a versatile and durable material that is resistant to corrosion and heat. It is lightweight and easy to work with, making it suitable for creating custom countertops in various sizes and shapes. Additionally, aluminum countertops offer a modern and sleek aesthetic, and they can be easily cleaned and maintained. However, it is important to note that aluminum is a softer metal compared to other materials commonly used for countertops, such as granite or quartz. This means that aluminum countertops may be more prone to scratches and dents. Nevertheless, with proper care and maintenance, aluminum sheets can be a viable option for manufacturing kitchen countertops.

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: Can aluminum sheet be used for solar panels?

- Yes, aluminum sheets can be used for solar panels. They are commonly used as the backing material or frame for solar panels due to their lightweight, corrosion-resistant, and durable properties.

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- The two previous bikes lack brazeons for rack mounts up front, so they don't seem suitable for heavy, loaded touring expeditions. But, I don't see any models by Giant that have front rack brazeons. Actually, their forks all appear to be carbon/composite. I agree that the Co-Motion products look great, but their prices do seem a bit high for a welded frame, even if it is made in the US. The Surly LHT would make an extremely rugged, steel tourer. But building it up to your desired specs would likely put you way over your limit.

- Q: What are the different methods for engraving aluminum sheets?

- There are several different methods for engraving aluminum sheets, each with its own advantages and applications. 1. Laser engraving: This is one of the most popular methods for engraving aluminum sheets. It uses a laser beam to vaporize the aluminum surface, creating a permanent and precise engraving. Laser engraving offers high precision, speed, and versatility, making it suitable for a wide range of applications. 2. Mechanical engraving: This method involves using a mechanical tool, such as a rotary cutter or diamond-tipped tool, to physically remove material from the aluminum surface. Mechanical engraving can achieve deep and detailed engravings, making it suitable for applications where durability and depth are important. 3. Chemical etching: Chemical etching involves using chemicals to selectively remove material from the aluminum surface. It is a highly precise method that can create intricate and detailed designs. Chemical etching is often used in industries such as electronics and aerospace, where precision and high-quality finishes are required. 4. CNC milling: Computer Numerical Control (CNC) milling is a method that uses a computer-controlled machine to remove material from the aluminum sheet. It can achieve precise and complex engravings, making it suitable for applications that require intricate designs or 3D engravings. 5. Hand engraving: Hand engraving involves using handheld tools, such as gravers or chisels, to manually create engravings on the aluminum surface. While it may not offer the same level of precision as other methods, hand engraving allows for artistic freedom and customization. Each method has its own advantages and limitations, so the choice of engraving method depends on factors such as the desired design, level of detail, production volume, and budget.

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- This okorder /.... Aluminum is a very different animal than steel, so the choice of alloy depends on what the application is. For instance, 7075-T6 is the most common high-end alloy for chainrings, but it has comparatively low tensile and yeild strengths.....and yet it's the most durable choice for the application. Chainrings made out of a stronger alloy won't last as long and may develop stress cracks. Some of the alloy choices depend upon machining and welding characteristics, too...it's not always about the strongest or lightest. You wouldn't want a part like a seatpost to be made of the material with the best numbers but that has a tendency to crack after welding.

Send your message to us

White Aluminum Checker Plate/Tread Plate Sheets for Stairs

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords