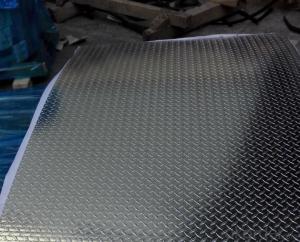

Black Diamond Plate Aluminum Sheets - 1100 3003 5052 5754 5083 6061 7075 Non-Slip Alloy Aluminum Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

1000 Series,3000 Series,4000 Series,5000 Series,6000 Series,7000 Series,2000 Series

Surface Treatment:

Coated,Embossed,Anodized,Polished,Mill Finish,Color Coated,Oxidized,Enameled Wire,Brushed,Printed,Composited,Holographic Impression,Sand Blasted,Powder Coating

Shape:

Angle,Square,T-Profile,Round,Flat,Rectangular,Oval,Hexagonal

Temper:

T3-T8,O-H112,T351-T651,T351-T851,Soft,Half Hard,Hard

Application:

Liner & Wad,Decorations,Door & Window,Heat Sink,Transportation Tools,Glass Wall,Food,Kitchen Use,Pharmaceutical,Seal & Closure,Insulation Material,Label & Tag

| Aluminum sheet/plate | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

| Packing : Export wooden pallets. The bundle wegiht not exceed 2MT. Loading:by 1x20GP, 1X20GP can load about 18MT | |||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

| Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

| MOQ | 100 kg | ||||

| Payment term: | T/T,L/C | ||||

| Delivery Time | 10 days after 30% T/T payment or receiving L/C copy | ||||

| Kind attention : Specifications can be customized as the customer’s requirements. | |||||

Packaging & Shipping

Payment: T/T with 30% prepayment and 70% balance payment against B/L copy.

Origin: China

Packaging: Standard Export Packaging or According to Customers' Requirements.

Delivery: 30 days

Minimum Order: 5 tons

- Q: I was hoping someone could explain aluminum corrosion with degreasers and cleaning formulas for automotive cleaning. This starts with, where is this aluminum (wheels)?, what types of cleaners?, do cleaners cause corrosion? Any insights would be appreciated.

- Contrary to popular believe, aluminum oxidizes just like steel. Steel rusts to a reddish color. Aluminum rusts to a white color and looks more like corrosion. Aluminum cleaners or cleaners safe for aluminum usually clean without staining the aluminum surface. Hardly any cleaner for for automotive use will corrode aluminum. Visit your local auto parts store and read the labels for a wheel cleaner that is 'safe' for aluminum. You should be able to use it on all aluminum surfaces.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminum is much cheaper and requires less structure to hold it up. It conducts very well. But is does not work well in homes because the expansion and contraction with heating loosens connections and those to copper wire need special wire nuts/grease

- Q: How does the grain structure of aluminum sheet affect its properties?

- The grain structure of aluminum sheet significantly affects its properties. The size, shape, and orientation of the grains within the sheet determine its strength, ductility, and other mechanical properties. A fine and uniform grain structure generally results in improved strength and formability, as the smaller grains hinder crack propagation and enhance grain boundary strength. On the other hand, a coarse or uneven grain structure can weaken the sheet and make it more prone to failure. Therefore, controlling and optimizing the grain structure during manufacturing processes is crucial to achieve the desired properties in aluminum sheet.

- Q: Can aluminum sheets be used for boat building?

- Yes, aluminum sheets can be used for boat building. Aluminum is a popular material choice due to its strength, durability, and resistance to corrosion. It is lightweight and easy to work with, making it suitable for constructing various types of boats. Additionally, aluminum boats are known for their longevity and low maintenance requirements.

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- To ensure a strong and durable bond between the adhesive and the aluminum surface, various surface preparation methods are available. One commonly used method is mechanical abrasion, where the surface of the aluminum sheet is roughened using abrasive materials like sandpaper or wire brushes. This creates a textured surface that enhances adhesive adhesion. Chemical etching is another option, involving the treatment of the aluminum surface with a chemical solution to eliminate any oxide layer and establish a clean and reactive surface. Depending on the adhesive's specific requirements, acids or alkalis can be utilized for this purpose. For adhesives that necessitate a contaminant-free surface, solvent cleaning can be employed. This process involves the use of solvents like acetone or isopropyl alcohol to eradicate grease, oil, or dirt from the aluminum sheet's surface. In addition to these techniques, specialized methods like anodizing and chromate conversion coating can also be utilized. Anodizing entails the creation of a thick oxide layer on the aluminum surface through an electrolytic process, thereby improving bonding properties. On the other hand, chromate conversion coating involves treating the aluminum surface with a chemical solution containing chromates, resulting in the formation of a protective layer that enhances adhesion. Ultimately, the selection of a surface preparation method depends on the adhesive's specific requirements and the desired bond strength. It is crucial to carefully choose and follow the appropriate method to successfully bond aluminum sheet with adhesive.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: This question asks for a list of various types of fasteners that can be used to secure aluminum windows to their frames.

- <p>There are several types of fasteners used for attaching aluminum windows to frames, including: 1. Screws: Commonly used for their secure hold and ease of installation. 2. Nails: Quick to use but may not provide the same level of security as screws. 3. Adhesives: Can be used for a more permanent bond, especially in certain applications. 4. Clips and brackets: Used for a more visible, decorative attachment. 5. Rivets: Provide a strong, permanent connection but are not easily removable. 6. Dowels and pins: Used for a more traditional or decorative join. 7. Structural glazing systems: Employ silicone or other sealants to bond the window to the frame. Each type of fastener has its own advantages and is chosen based on the specific requirements of the project, such as load-bearing needs, aesthetic considerations, and the desired level of permanence.</p>

- Q: Are aluminum sheets suitable for use in harsh chemical environments?

- Yes, aluminum sheets are suitable for use in harsh chemical environments. Aluminum has excellent resistance to many chemicals, including acids, alkalis, and organic solvents. It forms a protective oxide layer on its surface that helps prevent corrosion. Additionally, aluminum is lightweight, durable, and cost-effective, making it a popular choice for various industrial applications in harsh chemical environments. However, it is important to note that the suitability of aluminum sheets in specific chemical environments may also depend on factors such as temperature, concentration, and duration of exposure to the chemicals. It is always recommended to consult with experts or refer to specific chemical compatibility charts to ensure the appropriate selection of materials for a given chemical environment.

- Q: Can aluminum sheets be painted or coated?

- Yes, aluminum sheets can be painted or coated. Aluminum surfaces can be prepared and primed before applying paint or a protective coating. The paint or coating adheres well to the aluminum surface, providing a durable and aesthetically pleasing finish.

Send your message to us

Black Diamond Plate Aluminum Sheets - 1100 3003 5052 5754 5083 6061 7075 Non-Slip Alloy Aluminum Embossed Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords