Skid-Proof Aluminum Alloy Checker Plate for Fence - Best Price Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Skid-Proof Aluminum Alloy Checker Plate Description:

They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Skid-Proof Aluminum Alloy Checker Plate :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

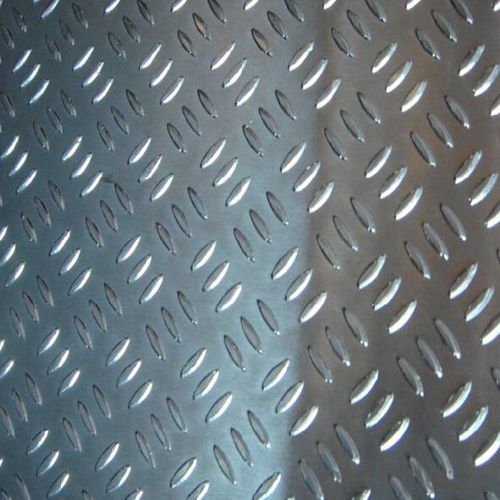

3. Skid-Proof Aluminum Alloy Checker Plate Images:

4. Skid-Proof Aluminum Alloy Checker Plate Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Al | ||

| Single | Total | ||||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | _ | _ | 0.05 | V:0.05 | 0.03 | 0.03 | _ | 99.6 |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | _ | _ | 0.05 | V:0.05 | 0.03 | 0.03 | _ | 99.5 |

| 1100 | Si+Fe:0.95 | 0.05~0.40 | 0.05 | _ | _ | _ | 0.1 | _ | _ | 0.05 | 0.15 | 99 | |

| 1200 | Si+Fe:1.00 | 0.05 | 0.05 | _ | _ | 0.1 | _ | 0.05 | 0.05 | 0.15 | 99 | ||

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~1.5 | _ | _ | _ | 0.1 | _ | 0.05 | 0.15 | R | |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0~1.5 | 0.8~1.3 | _ | _ | 0.25 | _ | 0.05 | 0.15 | R | |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0~1.5 | 0.20~0.6 | 0.1 | _ | 0.25 | 0.1 | 0.05 | 0.15 | R | |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30~0.8 | 0.20~0.8 | 0.2 | _ | 0.4 | 0.1 | 0.05 | 0.15 | R | |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50~1.1 | 0.1 | _ | 0.25 | _ | _ | 0.05 | 0.15 | R |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | _ | 0.1 | _ | _ | 0.05 | 0.15 | R |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | _ | 0.25 | _ | 0.15 | 0.05 | 0.15 | R |

| 5086 | 0.4 | 0.5 | 0.1 | 0.20~0.7 | 3.5~4.5 | 0.05~0.25 | _ | 0.25 | _ | 0.15 | 0.05 | 0.15 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To prevent scratches during transportation of aluminum sheets, there are several measures that can be taken: 1. Proper packaging: Ensure that the aluminum sheets are packaged securely in appropriate materials such as bubble wrap, foam, or cardboard to provide cushioning and protection from external impacts. 2. Use protective layers: Place protective layers such as paper or plastic film between individual sheets to prevent direct contact and minimize chances of scratching. 3. Secure stacking: When loading aluminum sheets onto transportation vehicles, ensure they are stacked securely to prevent any movement or shifting during transit. This can be achieved by using appropriate strapping or palletizing techniques. 4. Handling with care: Train personnel involved in the transportation process to handle the aluminum sheets with care, avoiding dragging or sliding them against rough surfaces that may cause scratches. 5. Avoid contact with sharp objects: Make sure that the aluminum sheets are not in contact with sharp objects or edges that may cause scratches. This can be achieved by keeping them away from other materials or using protective covers. 6. Regular inspection: Regularly inspect the aluminum sheets during transportation to identify any potential scratches or damages. If any are found, immediate action should be taken to prevent further damage. By following these preventive measures, the chances of scratches occurring during the transportation of aluminum sheets can be significantly reduced, ensuring that the sheets are delivered in optimal condition to their destination.

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- i heard plastic is more harmful i read in this article that a chemical found in plastic water bottle was found in this persons blood sample. But it was a small amount where it didnt cause any reactions . when cooking dont use aluminum to cover anything that has tomatoes they cause a bad reaction thats all i know i hope this helps

- Q: Is it possible to utilize aluminum sheets in interior design projects?

- <p>Yes, aluminum sheets can be used for interior design purposes. They are lightweight, durable, and resistant to corrosion, making them suitable for various applications such as wall cladding, ceilings, and furniture. Aluminum sheets can also be painted or anodized to achieve different finishes, adding aesthetic appeal to your design. However, it's important to consider the specific requirements of your project, such as load-bearing capacity and thermal insulation, as these properties can vary with different types of aluminum sheets.</p>

- Q: Are aluminum sheets suitable for water storage applications?

- Indeed, water storage applications can make use of aluminum sheets. Aluminum, being a lightweight and resilient substance, exhibits remarkable resistance towards rust and corrosion. Moreover, it possesses impermeability to water, air, and light, thereby rendering it an optimal selection for water storage. Furthermore, aluminum sheets can effortlessly be molded into diverse dimensions and configurations, enabling the creation of personalized water storage solutions.

- Q: Aluminum and oxygen gas react to produce aluminum oxide

- Aluminium oxide is Al2O3, so there are 3 oxygen atoms for every 2 aluminium atoms. Divide 75 by the relative atomic mass of oxygen (15.9994). That is proportional to the number of oxygen atoms. Then divide by 3 and multiply by 2. This gives a number proportional to the number of aluminium atoms. Then multiply this by the relative atomic mass of aluminium (26.981529) to give the mass of aluminium required in grams.

- Q: I'm about to fix the aluminum wiring in my house using Alumiconn connection, so I know that every outlet and switch plate need to be done, do the light fixtures need to be done as well? And also does anything need to be done with the main circuit breaker?

- I never understood why aluminum wire was ever used, it is inherently unsafe. I would replace the whole thing with copper.

- Q: What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- As long as it is spray paint, adhesion is not the same, if you want to firm, it is better to paint

- Q: Characteristics of anodized aluminium plate

- (1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.

- Q: Are aluminum sheets suitable for storage tanks?

- Yes, aluminum sheets are suitable for storage tanks.

- Q: This question asks for the steps or methods required to install aluminum sheets on a rooftop.

- <p>To install aluminum sheets on a roof, follow these steps: 1. Inspect the roof structure for any damage and ensure it can support the weight of the aluminum sheets. 2. Measure and cut the aluminum sheets to the required size using a metal saw. 3. Attach a drip edge to the eaves to prevent water from seeping under the sheets. 4. Lay the first sheet horizontally on the roof, starting from the bottom edge, and secure it with roofing nails. 5. Overlap the subsequent sheets by about 1-2 inches and fasten them with nails, ensuring a watertight seal. 6. Install flashing around vents, chimneys, and other roof projections to prevent leaks. 7. Seal all seams and fasteners with a high-quality sealant to ensure a weathertight installation. 8. Inspect the installation for any gaps or leaks and make necessary adjustments.</p>

Send your message to us

Skid-Proof Aluminum Alloy Checker Plate for Fence - Best Price Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords