Powder Coated AA5052 Hot Rolled Aluminum Strip

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Mill Finished Hot Rolled Aluminium Strip is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. And AA5052 is widly used in Ships building, industry ect, sometimes it also can used in the beer cans. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

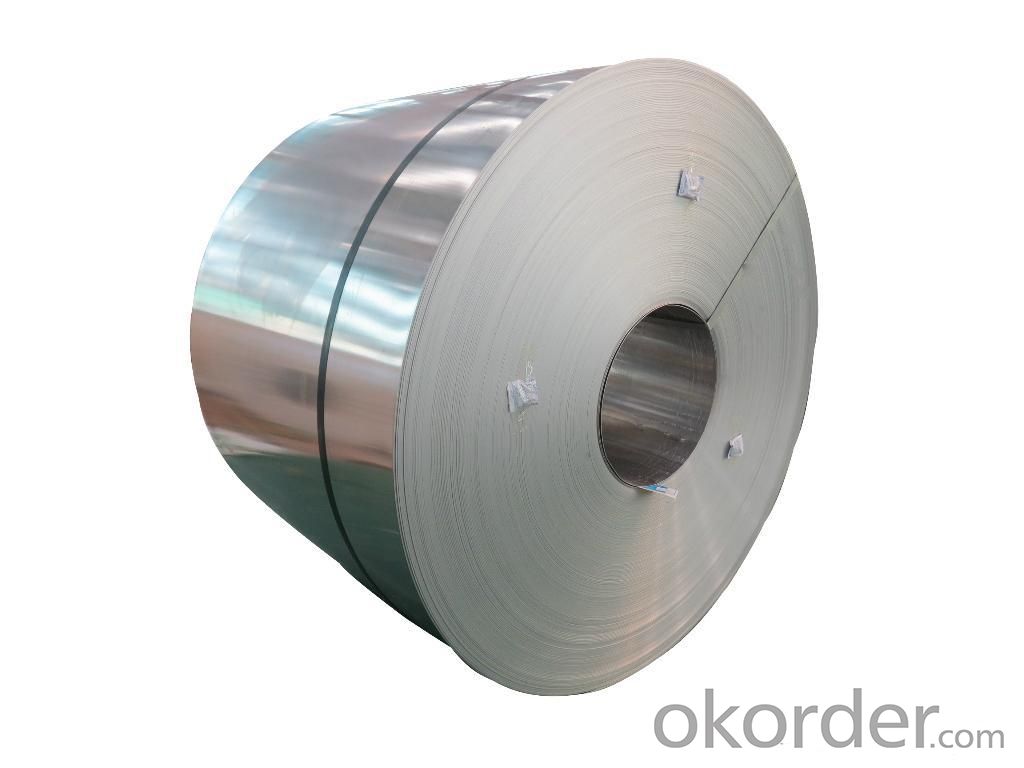

3. Image:

4.Products Specification

| Alloy | Thickness | Coil ID | Coil Weight | Main Usage |

| AA5052 | 0.2mm-3mm | 508mm+/-10mm | 2-2.5 tons | Ships |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on factors such as alloy composition, tempering, and thickness. However, generally, aluminum sheets have a moderate impact strength, making them suitable for many applications that require resistance to impact and denting.

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms due to their malleability and ductility.

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- This okorder ... Now for the bad news, most scrap yards DO NOT accept tabs, they try to say it's a lower grade of aluminium, which is not correct, as it is made out of the same sheet of aluminium as the can was. They just don't want to deal with it, or the people who alway's HEARD SOMEWHERE that tabs have some special value. The truth of the matter is that 1 pound of tabs (1,538 +/- tabs) is only worth about 40 cents. That's it, nothing more. Anybody who say's different is stupid, or a liar, there is no third option. Now, if you want to actually make some money, and your willing to do a little work, this is what I do. I take the tabs that i encounter in daily life, remove all damaged tabs (which are donated to McDonald's House Charities), then I sit there with a pair of needle nose pliars, and I remove that little curly thing that holds the tab to the can (which I save, and yes recycle as aluminium , over 220 pounds to date), now, count your tabs out into 1,000 count ziplock baggies. Each of these bags with 26 cents of aluminium will now sell on E-Bay for $4 plus shipping, which is $6.15 per pound. People need them for arts and crafts, I have sold literally millions on OKorder and my web site. The colored tabs are worth about 2 cents each, MONSTER and NOS tabs are worth about 5 cents each.

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- Aluminum foil can’t be used for heat retaining, it’s unsafe and hasn’t good efficiency. In this case, advice you use refractory cement to knot the coil and connect porcelain tube in the middle. It will Largely reduce the energy consumption produced by heat radiation.

- Q: Is it possible to utilize aluminum sheets in the construction of furniture?

- <p>Yes, aluminum sheets can be used for furniture. They are lightweight, durable, and resistant to corrosion, making them suitable for various types of furniture such as outdoor furniture, tables, chairs, and shelving. Aluminum's strength and flexibility allow for creative designs and easy maintenance. Additionally, it is a sustainable material that can be recycled, contributing to environmental sustainability.</p>

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: What is the typical density of aluminum sheets?

- Aluminum sheets usually have a density of around 2.7 grams per cubic centimeter (g/cm³). Unlike steel and other commonly utilized metals, aluminum is known for its lightweight nature and relatively low density. This characteristic makes aluminum sheets an ideal choice for multiple applications that require a material with less weight, including the aerospace industry, automotive manufacturing, and construction.

- Q: Are aluminum sheets suitable for chemical processing?

- Aluminum sheets, indeed, prove to be fitting for chemical processing. Renowned for its superb resistance to corrosion, aluminum has gained popularity as a preferred option for tasks involving exposure to diverse chemicals. It develops a shielding oxide layer that halts further corrosion, even in demanding surroundings. Additionally, aluminum's lightweight characteristic facilitates its handling and transportation within the chemical processing sectors. Furthermore, aluminum excels as a heat conductor, enabling efficient temperature regulation during chemical reactions. All in all, when considering their corrosion resistance, lightweight composition, and commendable thermal conductivity, aluminum sheets emerge as a prudent selection for chemical processing endeavors.

- Q: Is it possible to apply paint to an aluminum sheet roof after it has been installed?

- <p>Yes, you can paint your aluminum sheet roof after installation. However, it's crucial to ensure the surface is clean and free of any contaminants. Use a primer specifically designed for aluminum to enhance adhesion and durability. Apply a high-quality paint suitable for metal surfaces, following the manufacturer's instructions carefully. This process can help protect the roof from weathering and enhance its appearance, but it's recommended to consult with a professional to ensure the best results and longevity of the paint job.</p>

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum sheets are lightweight, making them easy to transport and install. This reduces the overall weight of the furniture, making it more manageable during assembly or rearrangement. Additionally, the lightweight nature of aluminum sheets allows for more flexibility in design, enabling manufacturers to create intricate and unique furniture pieces. Secondly, aluminum sheets are highly durable and resistant to corrosion. Unlike other materials like wood or steel, aluminum does not rust or deteriorate over time, making it suitable for both indoor and outdoor furniture. This durability ensures that furniture made from aluminum sheets has a longer lifespan, reducing the need for frequent replacements. Furthermore, aluminum sheets are highly malleable, allowing for easy shaping and customization. This flexibility in design enables furniture manufacturers to create furniture with intricate patterns, curves, and contours. Aluminum sheets can be easily molded into various shapes and sizes, providing endless possibilities for creativity and innovation in furniture design. In addition, aluminum sheets are low maintenance. They are easy to clean and require minimal upkeep, saving time and effort for both manufacturers and consumers. This makes aluminum sheets an ideal choice for furniture in high-traffic areas or public spaces where regular cleaning is necessary. Moreover, aluminum sheets are environmentally friendly. Aluminum is a highly recyclable material, meaning that furniture made from aluminum sheets can be easily recycled at the end of its life cycle. This reduces the impact on the environment and promotes sustainability in the furniture industry. Lastly, aluminum sheets offer excellent thermal conductivity. This means that furniture made from aluminum sheets can absorb and dissipate heat efficiently, providing comfort to users. In applications like outdoor furniture or items exposed to sunlight, aluminum sheets can prevent overheating and maintain a comfortable temperature. Overall, the advantages of using aluminum sheets in the furniture industry include their lightweight nature, durability, malleability, low maintenance, environmental friendliness, and excellent thermal conductivity. These properties make aluminum sheets a popular choice for furniture manufacturers, allowing them to produce high-quality, innovative, and long-lasting furniture pieces.

Send your message to us

Powder Coated AA5052 Hot Rolled Aluminum Strip

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords