Rhinomat Geomembrane

Rhinomat Geomembrane Related Searches

Rpp Geomembrane Reinforced Geomembrane Liner Geomembrane Rpe Geomembrane Xr Geomembranes Geomembranes Geomembrane Containment Conductive Geomembrane Bgm Geomembrane Raven Geomembrane Geomembrane Film Geomembrane Machine Rpp Geomembrane Liner Rowad Geomembrane Geomembrane Liners China Geomembrane Gse Geomembrane Textured Geomembrane Xr-5 Geomembrane Geocomposite Membrane Plastic Geomembrane Impervious Geomembrane Geomembrane Systems Permeable Geomembrane Geomembrane Cover Teranap Geomembrane Xr5 Geomembrane Geomembrane Material Bitumen Geomembrane Geomembrane ProductsRhinomat Geomembrane Supplier & Manufacturer from China

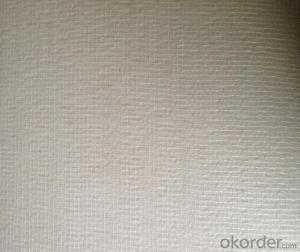

Rhinomat Geomembrane is a high-quality product designed for various applications in the field of geosynthetics. These products are engineered to provide excellent performance in terms of watertightness, durability, and resistance to environmental factors. They are commonly used in civil engineering projects such as landfills, reservoirs, and canal linings, where their impermeable properties help to prevent leakage and contamination.Rhinomat Geomembrane is utilized in a wide range of applications, including but not limited to, waste containment, water management, and environmental protection. The product's versatility makes it an ideal choice for projects that require a reliable barrier against water and other contaminants. Its robust construction ensures that it can withstand the pressures and stresses of various environments, making it a preferred option for professionals in the industry.

Okorder.com is a reputable wholesale supplier of Rhinomat Geomembrane, offering a vast inventory to cater to the needs of clients worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Rhinomat Geomembrane products they provide meet the highest standards of the industry. Their extensive stock allows them to promptly fulfill orders, making them a reliable choice for businesses and projects that require these geomembranes.

Hot Products