ECB Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ECB Geomembranes

Products Description

This product is extruded PE membrane formed by adding anti- oxidant, absorbent of ultraviolet and dyestuff into HDPE or LDPE or EVA and ECB will provide an effective barrier to of liquid water and water vapor.

Characteristics

·HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and

resistance to puncture .

·LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy

installation.

·ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

Products Specification

Name | Thickness(mm) | Width(m) |

HDPE | 0.75-2.5 | 4-8 |

LDPE | 0.2-2.5 | 4-8 |

EVA | 0.2-2.5 | 2-8 |

ECB | 1.0-2.0 | 2-8 |

Features:

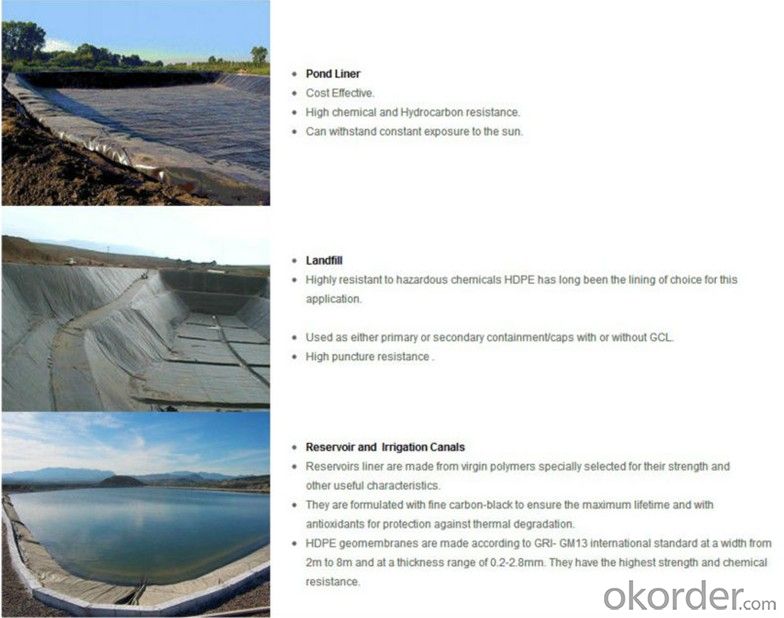

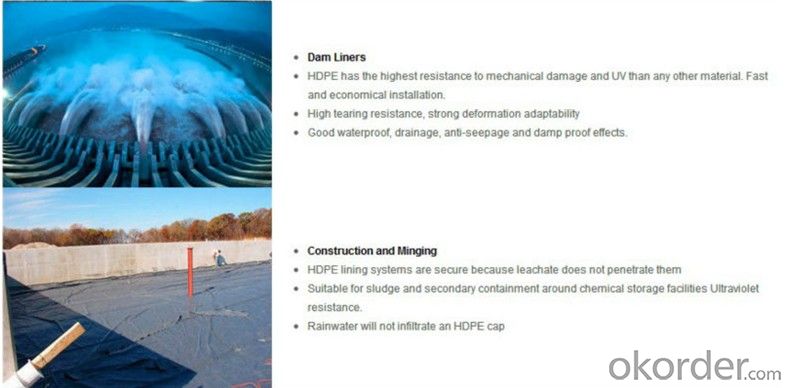

1.All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels,

and transportation project in most conditions.

2.Good aging, durable performance, and wide temperature range, it can be useful over

thirty years on the condition of -60æ«60æ.

3.Anti-stab and fine friction factors.

4.Canker proof, acid and alkali proof, untoxic.

5.Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6.Convevient to install and dependable effect.

Application Rage

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Yes, a waterproofing membrane can be used on tunnels with architectural features. Waterproofing membranes are versatile and can be applied to various types of structures, including tunnels with architectural features. These membranes are designed to create a barrier against water infiltration, protecting the structure from moisture damage. Whether the tunnel has unique architectural features such as curves, arches, or decorative elements, a waterproofing membrane can be customized and applied to ensure complete waterproofing. It is essential to consult with a professional waterproofing contractor who has experience in working with tunnels and architectural features to determine the most suitable membrane system for the specific project requirements.

- Q: Can a waterproofing membrane be used in hot climates?

- Certainly, hot climates are indeed suitable for the utilization of a waterproofing membrane. In fact, it is imperative to employ a waterproofing membrane in regions characterized by elevated temperatures and strong sunlight. The purpose of this membrane is to safeguard against water infiltration, which is of utmost importance in order to avert any harm to structures such as roofs, balconies, or basements. Furthermore, a top-notch waterproofing membrane is specifically engineered to endure the impacts of temperature fluctuations and UV radiation, guaranteeing its long-lastingness and efficacy even amidst scorching climates. Consequently, it is highly recommended to employ a waterproofing membrane in hot climates to ensure the resilience and integrity of the structures to which it is applied.

- Q: Can a waterproofing membrane be applied to existing structures or only during construction?

- Applying a waterproofing membrane is possible for both existing structures and those under construction. It is not solely limited to new constructions. In fact, it is quite common to retrofit existing structures with a waterproofing membrane to safeguard against water infiltration and moisture-related harm. The process involves surface preparation, addressing any existing damage or cracks, and applying the waterproofing membrane in accordance with the manufacturer's guidelines. To ensure its effectiveness and durability, it is essential to have a professional evaluate the suitability and compatibility of the waterproofing membrane with the existing structure.

- Q: Are waterproofing membranes suitable for crawl spaces?

- Yes, waterproofing membranes are suitable for crawl spaces as they provide a protective barrier against moisture and water intrusion, preventing issues such as mold growth, structural damage, and musty odors.

- Q: Can a waterproofing membrane be used for elevator pits or sump pits?

- One can utilize a waterproofing membrane for elevator pits or sump pits. These pits are prone to water intrusion, making it crucial to safeguard them against water damage. The purpose of a waterproofing membrane is to establish a barrier that prevents water from permeating the pits and causing harm to the structure or equipment. By applying this membrane to the walls and floors of the pits, it assists in maintaining a dry environment and preventing water infiltration. This, in turn, helps prolong the lifespan of the elevator or sump pump system and avoids expensive repairs in the future. Proper installation and maintenance of the waterproofing membrane are imperative to ensure its effectiveness and durability.

- Q: Can waterproofing membranes be painted over?

- Yes, waterproofing membranes can be painted over. However, it is important to ensure that the paint used is compatible with the membrane material. It is recommended to consult the manufacturer's guidelines or seek professional advice to ensure proper adhesion and longevity of the paint. Additionally, the surface should be clean and dry before applying the paint to ensure optimal results. Overall, painting over a waterproofing membrane can help enhance its appearance and provide additional protection against UV rays and other environmental factors.

- Q: Whether the polyester waterproofing membrane can be used for roofing waterproofing

- 2, roof waterproofing is not just a layer of waterproof membrane, according to the design of the coating is usually used waterproof layer + polyester membrane waterproof layer;

- Q: How long does it take for a waterproofing membrane to cure or dry?

- The time it takes for a waterproofing membrane to cure or dry can vary depending on various factors such as the specific product used, environmental conditions, and application method. However, on average, it usually takes around 24 to 48 hours for a waterproofing membrane to fully cure and dry. It is important to follow the manufacturer's instructions and allow sufficient time for the membrane to properly cure before subjecting it to water or other elements.

- Q: Does a waterproofing membrane require any specific curing time before it can be exposed to water?

- Yes, a waterproofing membrane typically requires a specific curing time before it can be exposed to water. The curing time allows the membrane to fully bond and form a protective barrier against water penetration. This time frame can vary depending on the type of membrane and manufacturer's instructions. It is crucial to adhere to the recommended curing time to ensure the membrane's effectiveness and durability. Premature exposure to water before the curing process is complete could compromise the membrane's performance and lead to water leakage or damage. Therefore, it is essential to follow the manufacturer's guidelines and allow the necessary curing time before subjecting the waterproofing membrane to water.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Yes, a waterproofing membrane can be used for water treatment plants. Waterproofing membranes are designed to prevent the passage of water and can be used to provide a barrier against water leakage in various structures, including water treatment plants. These membranes can be applied to different areas of the plant, such as tanks, reservoirs, pipes, and basements, to prevent water infiltration and protect the infrastructure from potential damage. Additionally, waterproofing membranes can help maintain the integrity of the water treatment process by ensuring that water remains contained within designated areas and does not seep into surrounding soil or structures.

Send your message to us

ECB Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords