Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

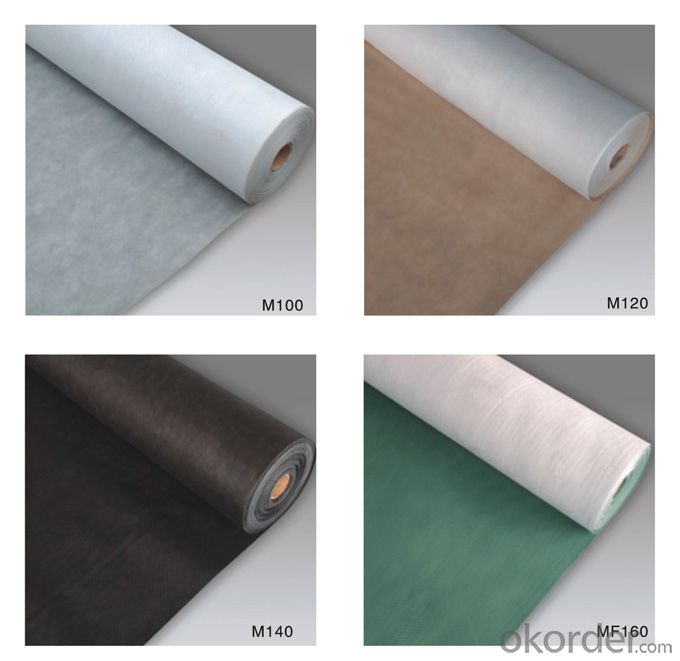

Breathable Membrane

Breathable membrane is thermal laminated by the high polymer material in the middle layer . Paving on the top of the insulation system, it can strengthen the water tightness of the building, as well as to eliminate humidity inside the containment by the unique breath ability, thus to retain the duration of building effectively , playing a part in thermal insulation, energy conservation and living environmental improvement.

We pay high attention to the quality of products, advance production equipments, perfect detection means, sound ISO system, powerful ability on technical research and management formed the preeminent “ Shanquan” quality.

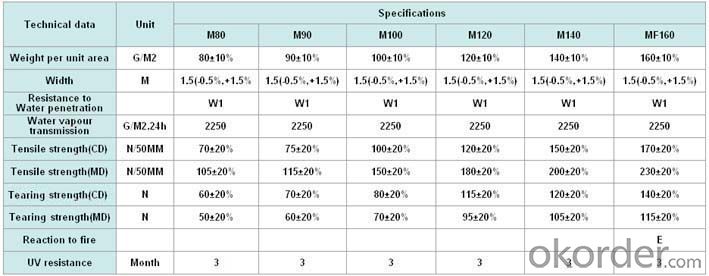

EN13859-1

- Q: Bathroom first leveling or do waterproof, what is the difference

- 3. Protective layer with cement mortar smooth. 4. backfill recommended the best use of ceramic, followed by light brick, commonly used slag, can also be overhead, cinder can also be less. Backfill attention to the protection of finished products.

- Q: Eastern rainbow waterproof how to do

- General family bathroom is brush JBL waterproof coating, buy back to the first dilution, and then clean up the ground with brushing uniform brushing, the bathroom should brush the ground and the wall 1.6 meters high,

- Q: What is the car waterproof sticker material?

- B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q: Can Henkel have water against him?

- Add a small amount of water is possible because the premise of waterproofing should also be wet before the grassroots

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- SBS Styrene-based thermoplastic elastomer is the largest yield (more than 70%) of SBCs, the lowest cost and wider application. It is a triblock copolymer with styrene and butadiene as monomer. Plastic and rubber properties, known as the "third generation of synthetic rubber".

- Q: Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: Villa roof leakage what general reasons, what materials to remedy

- Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar and cement mortar difference: Cement mortar is the synthesis of three main materials, cement, sand and water, and mixed mortar is the synthesis of four major materials, cement, sand, lime and water.

Send your message to us

Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords