EVA Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EVA Geomembranes

Products Description

This product is extruded PE membrane formed by adding anti- oxidant, absorbent of ultraviolet and dyestuff into HDPE or LDPE or EVA and will provide an effective barrier to of liquid

water and water vapor.

Characteristics

·HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and

resistance to puncture .

·LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy

installation.

·ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

Products Specification

Name | Thickness(mm) | Width(m) |

HDPE | 0.75-2.5 | 4-8 |

LDPE | 0.2-2.5 | 4-8 |

EVA | 0.2-2.5 | 2-8 |

ECB | 1.0-2.0 | 2-8 |

Features:

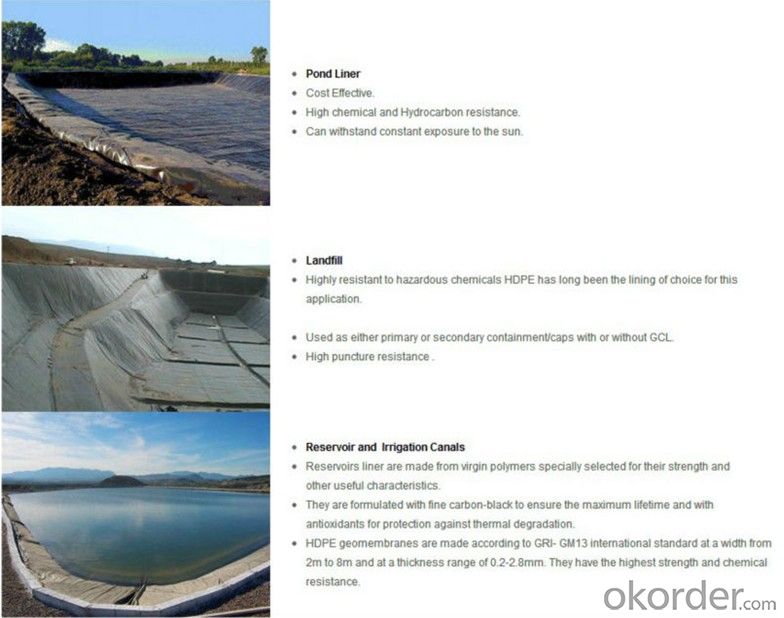

1.All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels,

and transportation project in most conditions.

2.Good aging, durable performance, and wide temperature range, it can be useful over

thirty years on the condition of -60æ«60æ.

3.Anti-stab and fine friction factors.

4.Canker proof, acid and alkali proof, untoxic.

5.Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6.Convevient to install and dependable effect.

Application Rage

- Q: How thick should a waterproofing membrane be applied?

- A waterproofing membrane should typically be applied to a thickness of at least 1.5mm to ensure effective protection against water infiltration.

- Q: Can a waterproofing membrane be used for a stadium seating area?

- Certainly! A stadium seating area can indeed benefit from the use of a waterproofing membrane. Such a membrane is specifically designed to safeguard against water intrusion into a structure. Its application in the realm of building construction is widespread, as it shields foundations, roofs, and walls from the detrimental effects of water. In the context of a stadium seating area, it can be effectively employed to prevent water infiltration by being applied to the concrete or any other flooring material. This measure becomes particularly crucial in outdoor stadiums, where rainfall or other forms of moisture can accumulate and potentially result in lasting structural complications. Consequently, the utilization of a waterproofing membrane ensures that the seating area remains impervious to water damage, thereby guaranteeing its durability and the safety of spectators.

- Q: Can waterproofing membranes be used on both horizontal and vertical surfaces?

- Yes, waterproofing membranes can be used on both horizontal and vertical surfaces. Waterproofing membranes are designed to provide a barrier against water penetration and can be applied on various surfaces, including roofs, walls, floors, and even underground structures. They are versatile in their application and can be used to protect both horizontal surfaces such as flat roofs or balconies, as well as vertical surfaces like walls or foundations. The flexibility and durability of waterproofing membranes make them suitable for a wide range of construction projects, ensuring that water does not seep through and cause damage to the structure.

- Q: Can a waterproofing membrane be used on underground structures?

- Yes, a waterproofing membrane can be used on underground structures. Waterproofing membranes are designed to provide a barrier against water infiltration and can be applied to various underground structures such as basements, tunnels, and foundations to prevent water damage and leakage.

- Q: Can a waterproofing membrane be used for both interior and exterior applications?

- Yes, a waterproofing membrane can be used for both interior and exterior applications. Waterproofing membranes are designed to prevent water penetration and provide protection against moisture damage. They are commonly used in basements, bathrooms, and other interior spaces to prevent water intrusion and dampness. Additionally, waterproofing membranes can also be applied to the exterior of buildings to protect against rain, snow, and other external elements. By using a waterproofing membrane for both interior and exterior applications, you can ensure comprehensive protection against water damage and maintain the structural integrity of your property.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Yes, a waterproofing membrane can be used in crawlspaces or basements. In fact, it is highly recommended to use waterproofing membranes in these areas to prevent moisture infiltration and water damage. Crawlspaces and basements are prone to water seepage and high humidity levels, which can lead to mold growth, structural issues, and damage to stored items. A waterproofing membrane acts as a barrier against water intrusion by effectively sealing the foundation walls and floor. It creates a watertight seal that prevents water from seeping into the space, keeping it dry and protected. Additionally, waterproofing membranes also help to control moisture levels by reducing condensation and humidity, thereby creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is an essential measure to ensure the longevity and integrity of the structure and to safeguard against potential water-related problems.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Using a waterproofing membrane in crawlspaces or basements is highly recommended. These areas are prone to water seepage and high humidity levels, which can cause mold growth, structural issues, and damage to stored items. By effectively sealing the foundation walls and floor, a waterproofing membrane acts as a barrier against water intrusion. It creates a watertight seal that keeps the space dry and protected. Furthermore, waterproofing membranes help control moisture levels by reducing condensation and humidity, creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is crucial for ensuring the structure's longevity and integrity and protecting against potential water-related problems.

- Q: Can a waterproofing membrane be used on tunnels with ventilation systems?

- Yes, a waterproofing membrane can be used on tunnels with ventilation systems. In fact, it is highly recommended to use waterproofing membranes in such tunnels to prevent water infiltration and potential damage to the tunnel structure or the ventilation system. The waterproofing membrane will create a barrier that prevents water from seeping into the tunnel, ensuring its integrity and protecting the ventilation system from water-related issues such as corrosion or moisture build-up. Additionally, using a waterproofing membrane can help maintain the efficiency and effectiveness of the ventilation system by preventing moisture or water vapor from entering the tunnel and potentially causing condensation or mold growth. Overall, using a waterproofing membrane in tunnels with ventilation systems is a crucial step in ensuring the long-term durability and functionality of both the tunnel and its associated ventilation system.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Yes, a waterproofing membrane can be used for wastewater facilities. Waterproofing membranes are commonly used in wastewater facilities to prevent water leakage and seepage. They provide an effective barrier against water infiltration and protect the structure from water damage. Additionally, these membranes are resistant to chemicals and can withstand harsh environmental conditions often found in wastewater facilities.

- Q: Can a waterproofing membrane be used for crawl spaces?

- Crawl spaces can benefit greatly from the use of a waterproofing membrane. It is highly recommended to incorporate a waterproofing membrane in these areas due to their susceptibility to moisture and water-related issues. The membrane acts as a protective barrier that prevents water infiltration, keeping the crawl space dry and safeguarding against dampness and the growth of mold. Typically, this membrane is installed on both the walls and floor of the crawl space, creating a sealed environment that effectively prevents water seepage. Moreover, certain types of waterproofing membranes also possess insulation properties, which can contribute to enhanced energy efficiency within the crawl space. Ultimately, the utilization of a waterproofing membrane in crawl spaces serves as an efficient method for averting water damage and maintaining a dry and healthy environment.

Send your message to us

EVA Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords