K1 Class Irradiation Cross-linkable LSZH High Flame Retardant Polyolefin for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LSZH compound:

1. Applications and cable specifications of LSZH compound:

Type | Product | Application and cable specification |

HF111-1 | K1 class irradiation cross-linkable POE insulating compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable non flame retardant inside insulation of nuclear power cables |

HF113-1 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant POE insulating compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable non flame retardant outside insulation of nuclear power cables |

HF113-7 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant POE filling compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable high flame retardant filling compound of nuclear power cables |

HF113-2 | K1 class irradiation cross-linkable low smoke halogen free high flame retardant POE jacket compound for nuclear power cables | 1E grade K1 class irradiation cross-linkable high flame retardant jacket of nuclear power cables |

HR113-2 | K1 class thermoplastic low smoke halogen free high flame retardant POE jacket compound for nuclear power cables | 1E grade K1 class thermoplastic high flame retardant jacket of nuclear power cables |

2. Description of LSZH compound:

low smoke halogen free flame retardant POE compound for nuclear power cable grade 1E class K1, based on POE resin, is produced and pelletized by special technology, adding special modifier, halogen-free flame retardant, anti-oxidant, crosslinking sensitizer and other special additives.

3. Processing of LSZH compound:

The following temperature(°C) profile of extruder is recommended:

| Type | Processing Equipment | Compression ratio | L/D | Processing temp. °C | Recommended vulcanize temp. | |||||

| Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die | |||||

| HF111-1 | Common rubber extruder | 1.1:1~1.5:1 | 20:1~25:1 | 90 | 140 | 160 | 165 | 165 | 160 | 10-15 megarad irradiation dosage |

| HF113-1 | 90 | 110 | 140 | 140 | 145 | 145 | ||||

| HF113-7 | ||||||||||

| HF113-2 | ||||||||||

| HR113-2 | 90 | 110 | 140 | 140 | 145 | 145 | ||||

4. Storage and transport of LSZH compound:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of LSZH compound:

| Item | Unit | HF111-1 | HF113-1 | HF113-7 | HF113-2 | HR113-2 |

| Standard | Standard | Standard | Standard | Standard | ||

| Tensile Strength | ≥MPa | 12.5 | 10 | 6 | 10 | 10 |

| Elongation at Break | ≥ % | 200 | 150 | 70 | 150 | 150 |

| Thermal Aging | °C×d | 135×7 | 135×10 | — | 135×10 | 110×10 |

| Variation on TS/ EB | ≤ % | ±25/±25 | ±30/±30 | — | ±30/±30 | ±25/±25 |

| Thermal Prolongation 20N/cm2 | °C×min | 200×15 | 200×15 | — | 200×15 | — |

| Elongation Under Load | ≤ % | 175 | 175 | — | 175 | — |

| Permanent Deformation | ≤ % | 15 | 15 | — | 15 | — |

| Volume Resistivity at 20 °C | ≥Ω.m | 1.0×1015 | 1.0×1012 | — | 1.0×1012 | 1.0×1012 |

| Dielectric Strength | ≥KV/mm | 25 | 20 | — | 20 | 20 |

| Oxygen Index | ≥ % | — | 30 | 40 | 30 | 30 |

| Impact Brittleness Temperature | °C | -30 | -30 | -15 | -30 | -30 |

| Smoke Density Flaming | ≤ | — | 100 | 100 | 100 | 100 |

| Non Flaming | ≤ | — | 350 | 350 | 350 | 350 |

| Acidity of gases evolved (PH) | ≥ | 4.3 | 4.3 | 4.3 | 4.3 | 4.3 |

| Conductivity of gases evolved | ≤μs/cm | 10 | 10 | 10 | 10 | 10 |

| Toxicity Index | ≤ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water Absorption Test | °C×h | 85×336 | 85×336 | — | 70×168 | 70×168 |

| Variation on TS/ EB | ≤ % | ±40/±40 | ±40/±40 | — | ±30/±30 | ±30/±30 |

| Ozone Resistance | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Irradiation Test 3300KGy | No cracking | No cracking | No cracking | No cracking | No cracking | |

| Thermal Life | years | 60 | 60 | 60 | 60 | 60 |

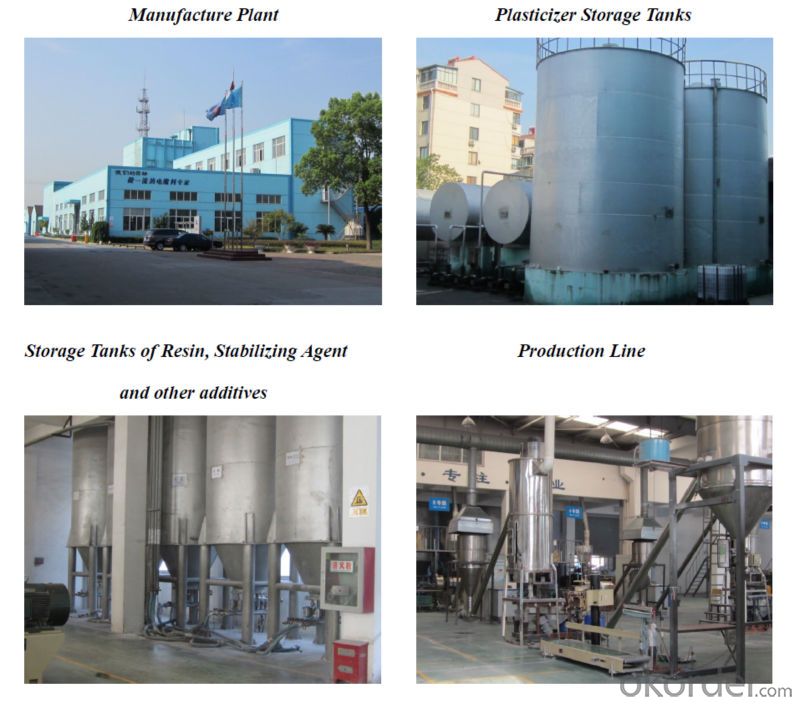

6. Company

- Q: What are the common raw materials used in plastic bottles? What are the main features?

- More common are PET, PP, PE, PC and so on.PET bottles are transparent, non-toxic, shock resistant, and resistant to high temperatures. They are usually filled with mineral water, cola, peanut oil and cosmetics. They must be filled in cold, disposable (not high temperature sterilized).

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q: What are the concepts, classifications and distinctions of modified plastics and plastic materials?

- Concept: modified plastics, refers to the base of the general plastics and engineering plastics, after filling, blending and enhancement processing method of modification, improve the performance of flame retardant plastic products, strength, impact resistance, toughness.Classification: modified plastic products are mainly a variety of flame retardant resins, toughening resin, plastic alloy, functional masterbatch etc..

- Q: Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: What are the POE plastic raw materials?

- Poe plastic raw material comes from petroleum or natural gas as the raw material of petroleum chemicals. It is a kind of macromolecule resin obtained by polymerization.

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- engineering plasticIt's a kind of plastic, and a universal plastic.Like everyday things, what barrels, pots, plastic, etc?.Engineering plastics generally have many properties that are not common in plastics. They are often used in construction machinery to replace certain metals.Plastic is resin and filler, so it is usually granular. Raw materials too. Only a few powdery.

- Q: What are plastic materials extracted from?

- Broadly speaking, any polymer compound that can be used as plastic material for processing raw materials is called resin. Resin is the main raw materials for the manufacture of plastics, paint is also used the system (the main film-forming material, coating such as alkyd resin, acrylic resin, synthetic fatty acid resin, the resin in the Yangtze River Delta and Pearl River Delta are also relatively strong in the paint industry, such as Changxin chemical, Nuplex resin, three resin, Ying DSM syntech resins), adhesives, insulating material, synthetic resin in industrial production, is widely used in separation and purification of impurities in liquid, with macroporous adsorption resin, ion exchange resin, and some special resin.

- Q: What is Ms plastic material?

- Transparent polymers were synthesized from methyl methacrylate (MMA) and styrene (SM) as the main raw materials.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- Compared with the ordinary PP, the filling PP has the advantages of less shrinkage, higher rigidity and good heat resistance, and is suitable for being used as an electric cooker, an inner ring, an automobile, a motorcycle fitting, etc..

Send your message to us

K1 Class Irradiation Cross-linkable LSZH High Flame Retardant Polyolefin for Nuclear Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches