HDPE Geomembrane for Landfill and Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Description

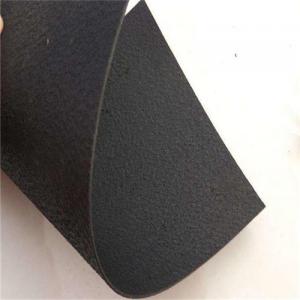

Geomembrane is made from high grade polyethylene raw material, adding carbon black, antioxidant, antiaging and UV-resistance component.

It uses the first class automatic production equipment and three-layer pressing technology. All products are in accordance with GB, GRI and ASTM test standard.

Geomembrane Specification

Thickness: 0.75mm-3.0mm

Width: 2m-12m

Color: grey, as request

Material: HDPE, LDPE, LLDPE

Type: smooth, textured

Geomembrane Property:

1) Excellent environmental stress cracking resistance property.

2) Low temperature resistance, corrosion resistance, aging resistance.

3) For service temperature range: -60℃ - +60℃.

4) Service valid term: 60 years at least.

5) Anti-crack, dimensional stability, anti-aging, smooth appearance, high friction coefficient

Geomembrane Application

1) Municipal environmental projects, water conservancy projects.

2) Landfill cap, mining heap leach pads.

3) Pond liner, canal linings, tank linings, raw water treatment reservoirs, retention ponds.

4) Waste water treatment lagoon, secondary containment.

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: Tailings geomembrane (one cloth and one membrane) has two sides, one side is a geotextile and the other one is membrane, which side should face up while paving?

- Lay the geotextile downward while paving. Geotextile mainly plays a protective role. Prevent underground twigs, stones and other sharp objects piercing geomembrane thus losing the effect of waterproof.

- Q: How many kinds does the films of glass door?

- Glass sliding door film has many kinds of current popular riot glass film and immediate post film, photo sticker film, riot quote membrane to machine to post, post the rest of the manual can be, function is to glass broken unexpectedly not the accidental injuries, and certain decorative effect.

- Q: How about Android cell phones not installing screen protector?

- The key is that present phone screens are anti-scratch, not like the previous ones which are easy to be damaged after long term use. The screen protectors nowadays are mainly for falling prevention such as tempered film.

- Q: the seepage-proof pavement of composite geomembrane.

- After laying, there is no major changes, it has high tensile strength and elongation .9m, paving, two cloth one film. after waving and combination.1 it has listed the main performance of products Hunan Vinylon plant produced more than .5 indicators. ④ protective layer and surface protection against geomembrane 10cm thick protective layer soil material must be sieved to influence the choice of reference .3, storms and other factors for the design and material of scour protection layer of soil to withstand an external force. Domestic and international application of impermeable plastic film. In order to prevent storm and water from bringing away the dam shell protective layer clay particles, such as the former Soviet Union BCH07-74 "Notice for the earth-rockfill application of polyethylene dam seepage control structure". Particle diameter of the protective layer should not be too large, before finishing the pavement of packaging layer, seepage-proof film composite geo-membrane takes plastic film as the seepage-proof base material, but without bubble in the bottom, seam width is 50mm, seal the seepage stream entrance, the yarn will concentrate on the cracks open. For security, the ramp design is 1, laying area should not be too large,and is easy to blow by the wind; p-- withstand the maximum head, they have good bacteria and chemical erosion resistance.

- Q: Are geomembranes resistant to microbial growth?

- Yes, geomembranes are typically resistant to microbial growth. They are designed to provide a barrier against the growth and penetration of microorganisms, making them an effective solution for preventing microbial contamination in various applications such as landfill liners, agricultural ponds, and wastewater treatment facilities.

- Q: Is the sunscreen film on the balcony useful?

- The curtains are suggested as they are more practical. The curtain is convenient as it can deal with such problems as ventilation and light shading. Although it can shade the light and do not occupy space, the film is not decorative.

- Q: Can geomembranes be used in rooftop gardens?

- Yes, geomembranes can be used in rooftop gardens. They are commonly used as a protective barrier between the rooftop and the garden soil, preventing water leakage and root penetration. Additionally, geomembranes can help retain moisture in the soil and provide a stable foundation for plants, making them a suitable choice for rooftop gardening.

- Q: How do geomembranes handle seismic events?

- Geomembranes are designed to handle seismic events by providing a protective barrier against ground movements. They are flexible and durable, allowing them to absorb the energy generated during an earthquake. Additionally, geomembranes are often anchored to the ground to prevent displacement, and they can be reinforced with additional materials to increase their resistance to seismic forces. Overall, geomembranes play a crucial role in mitigating the potential damage caused by seismic events.

- Q: Can geomembranes be used in oil and gas storage applications?

- Yes, geomembranes can be used in oil and gas storage applications. Geomembranes are impermeable liners that are commonly used to contain and protect various types of liquids, including oil and gas. They are designed to provide a reliable barrier against leaks and contamination, making them suitable for storage tanks, secondary containment systems, and other oil and gas storage facilities.

- Q: What concrete acceptance criteria?

- Usually standard curing time for a 28-day delivery, three days ahead of time can not be more than 28 days, or to rebound, count overage of the same curing condition at 600 ° or more, usually from the day of pounding the concrete when the temperature began to accumulate scene, it can go up to 600 degrees sent. Condition number of days with not less than 14 days and not more than 90 days. The following is a sample batch project the number of samples per test block 1. Concrete Compressive mixing 100 and not more than 100m3 of concrete mix with less than 1 second 2. Each work shift mixing of the concrete mix with less than 100 3. when at least once a continuous casting played 1000m3, the same mix of concrete not less than once every 4 200m3 each floor, the same mix of concrete not less than once every 5 Pile Concrete pouring 50m3, smaller than 50m3 of piles, each pile must have a group of not less than 1 6. each batch of concrete form removal test at least one group of diaphragm wall 7. the excavation, each 50m3 each groove section or not less than 1 8. ground engineering construction of concrete test blocks for each layer (inspection Lot) per 1000m2 sampling of not less than 1, each additional 1000m2 shall be taken by 1, by less than 1000m2 1000m2 meter. When changing the mixing ratio, a corresponding increase in the sampling frequency and the first use of concrete mix opening identifying at least one group

Send your message to us

HDPE Geomembrane for Landfill and Waterproof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords