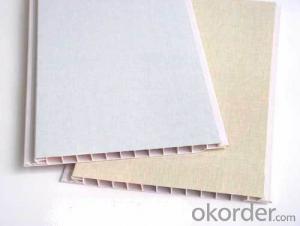

4*8 foam sheets pvc celuka board display panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

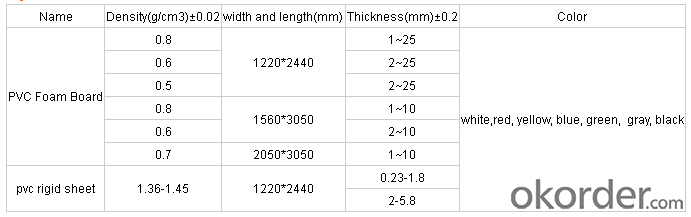

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

Product Features

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Pictures

- Q: What is the raw material used in the production of plastic products?

- Common mineral water bottles and carbonated beverage bottles are made of this kind of material which can not be recycled or hot water. Its heat-resistant temperature is only 70 degrees, only suitable for warm drinks or cold drinks, high temperature liquid or heating, easy to deformation, will dissolve the harmful substances. The scientists also found that the plastic could release carcinogens in 10 months. Therefore, when the beverage bottle is used up, it should be thrown away. It should not be used as a drinking cup or used as a storage container to hold other foods, so as not to cause health problems.

- Q: What are the concepts, classifications and distinctions of modified plastics and plastic materials?

- Modified plastics should, in principle, be made from the plastic raw materials produced by petrochemical plants. By adding plastic additives, they can enhance their hardness, fire resistance, high temperature or low temperature, weather resistance and ultraviolet resistance. Therefore, modified plastics are processed from plastic raw materials, which is the relationship between source and flow.

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the barrel is "1", the main component of this kind of plastic bucket is polyethylene terephthalate (polyester), which is often called PET. The melting point of this kind of plastic barrel is high, but the heat resistance can only reach 70 degrees centigrade, and it is easy to deform. When the temperature of the plastic barrel is higher than that of the plastic bucket, the possibility of dissolving harmful substances in the plastic barrel is increased, and the material such as wine, oil and the like can be easily twisted and contracted. As China has traditionally been thrifty, people tend to reuse plastic buckets. However, this kind of plastic barrels of repeated use, may release carcinogenic DEHP, if such liquid plastic barrel by people drinking, will may be suffering from cancer, also has toxicity to male testis, its harm should not be overlooked.

- Q: How many types of plastics are there?

- PP: the name for polypropylene, five-star pin, handrails, floor mats and high strength is not necessary connections. Disadvantages: poor wear resistance and low surface hardness.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- PA6 also known as nylon 6 is translucent or opaque white particles, thermoplastic, light weight, good toughness, chemical resistance and good durability and other characteristics, generally used for auto parts, machinery parts, electronic products, engineering accessories and other products.

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Plastics can be divided into two major categories: General Plastics and engineering plastics. They are usually granular or powder in order to be easy to process before they are madeGeneral plastics refer to common plastics with large output, wide use, good formability and low price. Such as PVC, polyethylene, polypropylene, polystyrene and so on. Products made of plastic film, pipe, woven bags and plastic daily necessities. The yield and consumption of general-purpose plastics account for more than 80% of all plastics.Engineering plastics refer to plastics that meet the needs of industrial parts. Relatively speaking, they yield large, wide range of applications. Mainly ABS, polycarbonate, nylon, POM, modified polyphenylene ether, thermoplastic polyester and so on. Products have TV casing, plastic gears, optical materials, gaskets and so on.There is also a special engineering plastics, in addition to its characteristics of engineering plastics, its comprehensive performance is higher, long-term use temperature above 150 degrees celsius. It also has special functions and special uses. Mainly used in high-tech industries, such as atomic energy, rockets, satellites, aerospace, automotive, electronic and sports equipment, and other structural materials. Commonly used special engineering plastics are fluorine plastic, silicon resin, polyimide, peek, liquid crystal polymer and so on.

- Q: What machines and materials are needed for the manufacture of disposable plastic cups?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water). In general plastics, PP has the best heat resistance, and its thermal deformation temperature is 80-100 DEG C and can be boiled in boiling water. PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"". PP products are light, tough and chemical resistant.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: What are the raw materials for producing plastic bowls and cups?

- Mostly PP, PE, these two.

- Q: How many kinds of plastic raw materials are there? How to distinguish them?

- Plastic with its superior performance gradually replaced many has been used for decades, hundreds of years of materials and utensils, becoming an indispensable assistant. Plastic and metal in hard wood, light transparent glass ceramic, corrosion resistance, rubber elasticity and toughness in a body. Therefore, in addition to daily necessities, plastic more widely used in aerospace, medical equipment, petroleum chemical industry, machinery manufacturing, defense, construction and other industries.

- Q: Chemical, plastic raw materials, plastic raw materials how sub grade?

- That's because the raw material used for making plastic barrels is different. Just like the quality of the clothes, the grades of the fabrics used are different, and the products presented are definitely different.

Send your message to us

4*8 foam sheets pvc celuka board display panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords