Chemical Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyolefin:

1. Applications and cable specifications of Polyolefin:

Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc.

Type | Product | Application and Cable Specification |

YJZD90 | 90℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD105 | 105℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD125 | 125℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD150 | 150℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

2. Description of Polyolefin:

Chemical cross-linkable POE compound for cables and wires, based on POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, halogen-free flame retardant, cross-linking agent and other special additives. The compound has well thermal deformation resistive and mechanical properties. It suits the cables and wires manufacturers who have rubber production lines, and need not irradiate.

3. Processing of Polyolefin:

The compound could be processed in common rubber extruder, and the recommended processing temperature is 100°C.The user could adjust the temperature properly according to extruder and wires and cables surface status.

Vulcanize processing of the compound could refer to rubber. The details of extrude speed, Vulcanize temperature and time could be adjusted properly according to the equipments and cross-linked status.

4. Storage and transport of Polyolefin:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of Polyolefin:

| Item | Unit | YJZD90 | YJZD105 | YJZD125 | |||

| Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.45 | -- | 1.45 |

| Hardness | Shore A | -- | 92 | -- | 91 | -- | 89 |

| Tensile Strength | ≥ MPa | 12.5 | 15 | 12.5 | 14.5 | 12.5 | 14.8 |

| Elongation at Break | ≥ % | 150 | 170 | 150 | 165 | 150 | 160 |

| Thermal Aging | |||||||

| Aging Temperature | degree C | 135±2 | 135±2 | 135±2 | 135±2 | 158±2 | 158±2 |

| Aging Time | h | 168 | 168 | 240 | 240 | 168 | 168 |

| Retention of Tensile Strength | ≥ % | 80 | 110 | 80 | 106 | 80 | 110 |

| Retention of Elongation at Break | ≥ % | 80 | 105 | 80 | 98 | 80 | 93 |

| Thermal Prolongation: 20N/cm2 | degree C×min | 200×15 | 200×15 | 200×15 | |||

| Elongation Under Load | ≤ % | 175 | 25 | 175 | 25 | 175 | 25 |

| Permanent Deformation | ≤ % | 15 | 0 | 15 | 0 | 15 | 0 |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1011 | 1.1×1012 | 1.0×1011 | 2.0×1012 | 1.0×1011 | 1.2×1012 |

| Dielectric Strength | ≥KV/mm | 20 | 24 | 20 | 24 | 20 | 25 |

| Oxygen Index | ≥ % | 28 | 32 | 28 | 32 | 28 | 33 |

| Impact Brittleness Temperature | degree C | -25 | pass | -25 | pass | -25 | pass |

| Smoke Density Flaming | ≤ | 100 | 66 | 100 | 67 | 100 | 67 |

| Non flaming | ≤ | 200 | 147 | 200 | 146 | 200 | 148 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.3 | 4.3 | 5.4 | 4.3 | 5.3 |

| Conductivity of gases evolved | ≤μs/cm | 2.5 | 1 | 2.5 | 1 | 2.5 | 1 |

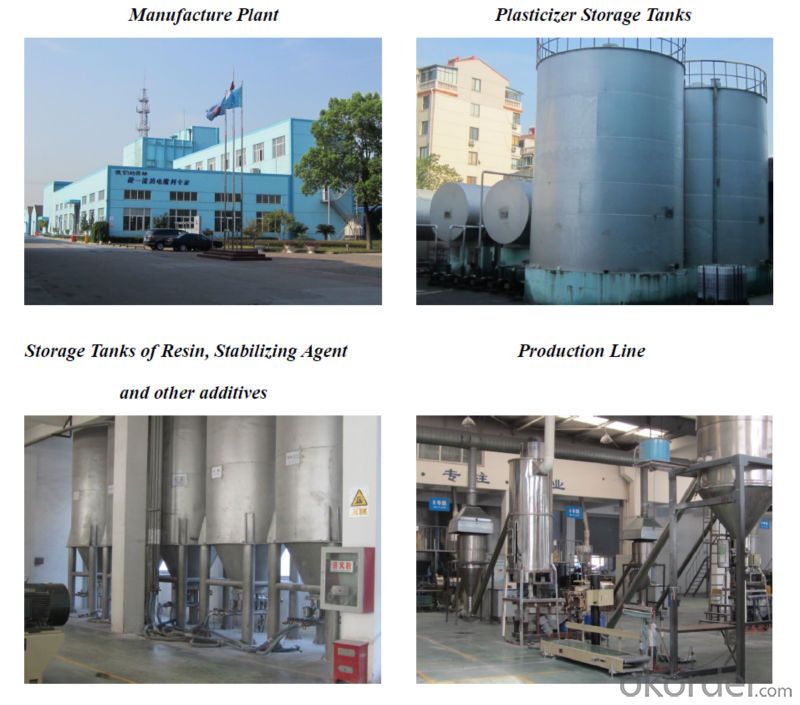

6. Company

- Q: I'd like to know what PP plastic material is PP plastic raw materials cleaning can not use ultrasonic cleaning machine to wash it?

- PP plastic raw material is a thermoplastic resin. Its density is small, strength, stiffness, hardness, heat resistance are better than low-pressure polyethylene, can be used in about 100 degrees. With good electrical properties and high frequency insulation, free of moisture, but brittle at low temperatures, wear and aging, suitable for making general mechanical parts, corrosion resistant parts and insulation parts.

- Q: What are the raw materials of foam plastics and how do they come out?

- Chemical blowing agents are mainly azo organic compounds such as azo two formamide (ADCA or AC), 2, 2 '- azo two, DAB, AIBN, etc.. This kind of foaming agent is cheap, and the products are non-toxic, odorless and colorless. In addition to sulfonylhydrazine, such as 4, 4 '- oxo benzene sulfonyl hydrazide (OBSH) etc.. Attention should be paid to the decomposition temperature. The properties of chemical foaming agents are as follows:Azo two formamide (AC, ADCA). Orange crystalline powder. A large amount of gas (N2, CO and a small amount of CO2) is decomposed at 120 DEG C, and the gas yield is 200 ~ 300mL/g in the standard state, which is an efficient foaming agent.

- Q: How many kinds of plastic do you have?

- B. foam:Foam plastics can be divided into three kinds of hard, semi hard and soft foam. Hard foam without flexibility, compression hardness is very big, only up to a certain stress deformation, stress the lifting of restitution; soft foam rich flexibility, compression hardness is very small, very easy to deformation, stress release after can restore the residual deformation small; semi rigid foam between flexibility and other properties between hard and soft foam.

- Q: Is the tableware made of PP raw material the best of those plastic tableware?

- 1 polyethylene terephthalate (PET) is made up of ethylene. Used as mineral water bottles, cola beverage bottles, fruit juice bottles, etc.. Because it can only heat 120 degrees, so only suitable for cold and warm drink, if installed high temperature liquid or heating deformation.2. High density polyethylene (HDPE), suitable for food and medicine bottles, cleaning supplies and bath products, shopping bags, garbage cans.3. Polyvinyl chloride (PVC) is polymerized from vinyl chloride. High temperature and contact with grease, PVC easily release phthalate two formic acid and incompletely polymerized toxic vinyl chloride monomer. PVC film made of PVC, transparent, difficult to break, strong adhesion, low prices, we see in the supermarket, supermarkets on the box firmly glued to the film is it. According to its characteristics, it is only suitable for vegetables and fruits refrigerated preservation, it is not appropriate to put meat, cakes and other foods containing more fat, it should not be used as microwave heating

- Q: PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- PP and PE plastic corrugated pipe in the role of the following two: 1, PP material can reduce the production of pipe, HDPE than PP pipe grade market sales price higher, the production of HDPE pipeline adding appropriate amount of PP, for the reduction of raw materials

- Q: What raw materials do plastic color printing plants use?

- PEBOPPOPS film, aluminum film and so on, the ink is usually water-based ink, polypropylene ink, etc., different films with different ink.

- Q: What are the raw materials for producing plastic bowls and cups?

- Now the plastic bowl is basically made of PP, the quality is better. What's more, the PP bowl can be baked in a microwave oven, and other plastics will not.

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: How to test plastic raw materials?

- Sample appearance quality. The plastic raw material is produced according to the normal production process, and the appearance quality of 10~20 parts is observed. The sample product shall not be cracked, deformed, foamed, broken, expanded or shrunk, and other defects that affect appearance. Smooth surface and clear surface.

- Q: Do you have plastic materials that are low in price instead of ABS?

- The H series of PP sells for only $13.5, and /KG and ABS are lower.

Send your message to us

Chemical Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches