Concrete Formwork Plywood

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Pieces cm²

- Supply Capability:

- 5000 Piece/Pieces per Day cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

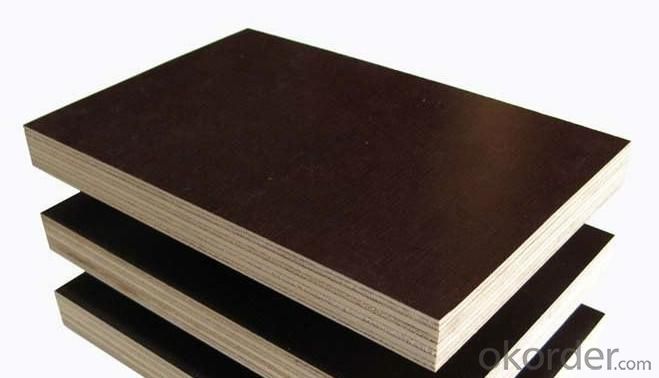

1 . Introduction of Concrete Formwork Plywood

High-grade raw materials;

High quality, low price;

Dimensional stability.

Concrete formwork plywood

2 . SPECIFICATION OF Concrete Formwork Plywood

1) Core:Poplar,Combi,Hardwood

2) Film: Brown,Black,Red

3) Size: 1220*2440/ 915*2135/ 1250*2500MM

4) Thickness: 18/21MM

5) Thickness tolerance:Minus or plus 0.2-0.5MM

6) Moisture content: 8%-12%

7) Quantity: 8pallets/20FT,16pallets/40FT,18pallets/40HQ

8) Packing: Negotiable

9) GLUE:WBP phenolic,MR,E1,E2.

10) Price advantage: 20-30% cheaper than others based on same quality

11) Design ability: We can offer you a general proposal based on your structural drawings

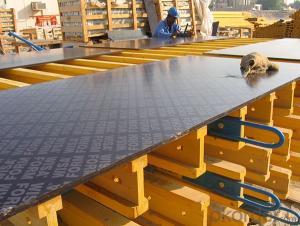

3 . CHARACTERISTICS OF Concrete Formwork Plywood:

This plywood can be used at timber beam system,steel formwork system,aluminum frame slab formwork.

Component with high standardization

Assembling in site,flexible application

Light weight,easy transportation and storage

Used with timber beam system step 1

Used with timber beam system step 2

Used with timber beam system step 3&4

4 . PROJECT APPLICATION OF Concrete Formwork Plywood

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change: one is the scaffold without turning over shelf, two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Advantages and disadvantages of climbing frame and floor type scaffoldPjal | browse 5789Recommended 2016-09-21 09:11:21 best answerClimbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. But it also has the disadvantage of fixed structure.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 1949 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 200 |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Formwork Plywood

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Pieces cm²

- Supply Capability:

- 5000 Piece/Pieces per Day cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords