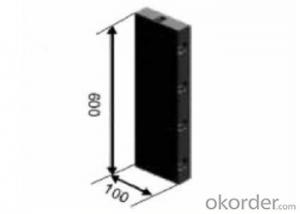

10 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

10 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

Description:

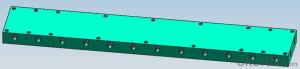

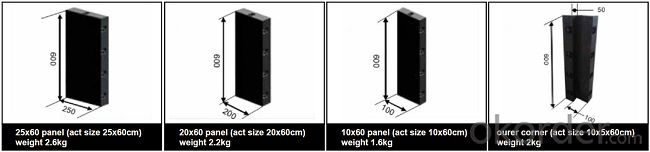

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm),25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

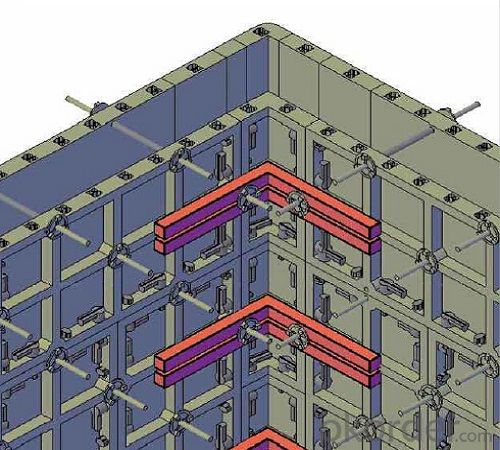

Walls and Corners

Using modular formwork, it is possible to pour up to 40cm thick and 3 meters high straight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gang forms by hand.

Project Gallery

Advantages:

1. Easy Set Up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2. Modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

3. Strength

The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures. The handles are made by high strength Nylon, each panel

locked by at least 4 handles, which makes the whole system strong enough to pour 40cm walls.

4. Environment Friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

5. Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- Plastic mold is better, light weight, high impact strength, easy assembly, high turnover rate, smooth surface, no moisture, no mildew, Naisuan Jian, no cracking, large plate, less joints, can be saw, can Nail, can be processed into any length and so on

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- In summary, what template to use depends on what your structure needs.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template made of what material

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- Q: Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- Can be ruled length processing, can be ruled length processing, can be ruled length processing

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

10 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords