concrete wall formwork system for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Q235 cold-rolled steel

Surface Treatment: Electro paint

Color: Gray/yellow

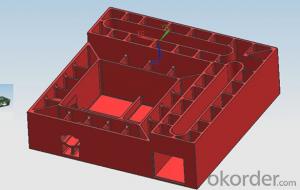

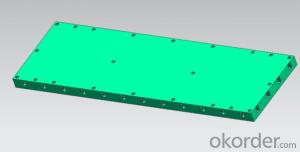

Combination: vertical beam, cross beam, tie rod &nuts, cross shape spacer, door way clip, connecting beam, corner beam, fastener.

Specification:

Packaging & Shipping

According to the customer's request, suitable for shipment.

Details:

Vertical Beam: it’s a single square tube with adjustable length, to be nailed on the plywood. The normal size is 2.2m-2.6m and 2.6m -3.0m. Two vertical beams can be connected together to reach any height you need.

Cross Beam: we have both single-tube cross beam and double-tube cross beam. It can be connected with the vertical beam by the tie rod & nut and cross shape spacer

Tie Rod & Nut: it is used along with the cross shape spacer to secure the plywood.

Cross shape spacer: it can be easily connected with the Tie Rod.

300*300 Corner Beam: it is used in the inside corner to ensure the corner is straight. One end of the inner corner beam is fixed, the other end is telescopic.

- Q: Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic construction template is not a good place to say, talk about the shortcomings of it, 1: the quality is too heavy, 2 intensity is not very satisfactory, 3, a little fee wooden side

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: Plastic mold dynamic template, the size of the template

- Bigger than the fixed model on the line, a good folder folder.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

Send your message to us

concrete wall formwork system for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 mm

- Supply Capability:

- 30000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords