Foam Concrete Pouring Plastic Formworks for House

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Plastic PVC Foam Board Formworks Introduction

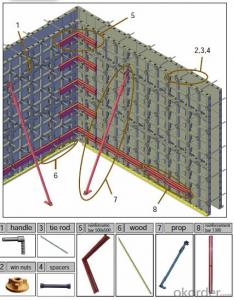

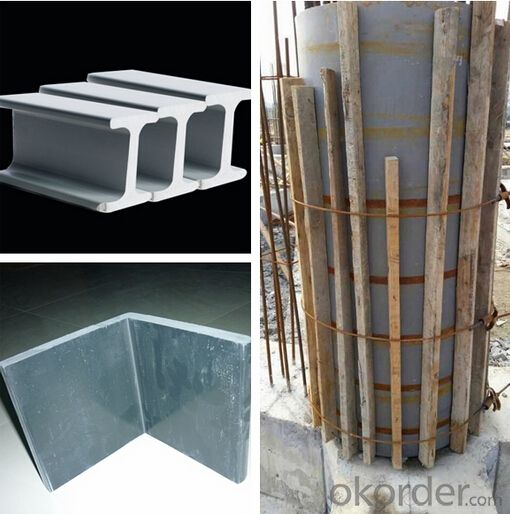

This kind of construction formwork can be special form like column and square.

They can be used in bridge, office building and roads construction.

Our products have characters such as energy conservation, environment-protection, and in low price. Another, turnovers can be up to 30 times, temperature adaptation range is wide. Plastic steel template can be any sizes so that it has wide adaptation.

easy installed and removed, sawed and drilled, and accessories complete.

save working hours more than 30% and increase efficiency more than 40%.

save construction template allocable cost over than 50%

Product features

1.Long lifespan& Cost effective –The experiment shows that our Plastic Formwork can be reused over 100 times, while the Plywood can only be reused 7 to 10 times. Therefore the Plastic Formwork increases the cost efficiency.

2.Waterproof – For the nature of plastic material, this item is a kind of anticorrosive material, especially suitable for underground and watery circumstances.

3. Easy reassembly– It is easy for worker to operate and split.

4. Pouring expediently-- The template will be separated easily from concrete.

5. Simple Installation – the mass of the product is light, at the same time it is safe to handle and easy to clean.

6. High Quality –it is hard to deformation.

7. Recyclable -- Waste scrap molding board could be recycled.

Product size

1.Wall panel :1200*600mm,100*600mm, 200*600mm,250*600mm, 600*10mm,600*20mm

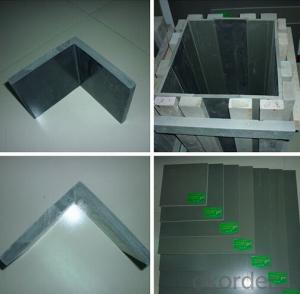

2.Corner:inner corner 200x200x600mm and outer corner 100x50x600mm

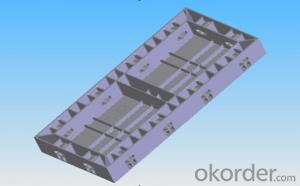

3.Square Column:750*730*70mm(thickness of wall can be adjusted from 200- 600mm with per 50mm increment)

4.Round Column:750*400mm,750*300mm

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.

- Q: Why the floor is not plastic building materials square wood and template

- Not people do not have this product is not humane is not perfect not to buy only to be used to solve the trouble of the workers with the boss's doubts

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- Hardware stores have, any one hardware store can buy, you can buy the nearest.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

Send your message to us

Foam Concrete Pouring Plastic Formworks for House

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords