Aluminum-frame Formwork for Concrete Processing

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork GK120 Description

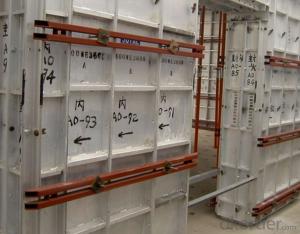

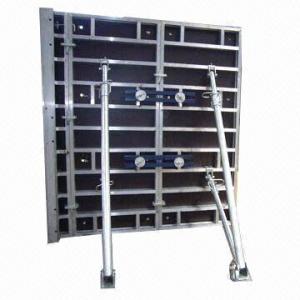

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand. Framed formwork is often used combining with the climbing formwork system or wall formwork system to substitute the timber beam formwork. Both combinations are acceptable on construction site.

2. Main Features of Steel Frame Formwork GK120

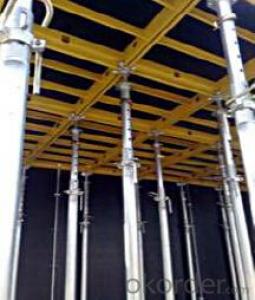

◆ The complete formwork system for slab casting, easy & quick assembly.

◆ Light panel weight, easy to carry.

◆ Economical, versatile & hi-speed formwork system; comes with a permissible slab

thickness of 400 mm.

◆The adjustable clamps are convenient to use and hold firmly.

◆There is a prizing part designed in the corner, which can help to position and remove formwork easily.

◆The formwork is screwed on from the back when connecting frame and plywood, and the surface of the finished concrete is perfect.

◆ Working efficiency is greatly improved by fast erection and dismantlement.

◆ The panel can be supported by both props and scaffolding.

◆ High standardization with components.

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120Specifications

Steel Frame Formwork GK120 is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork. 1050 series /750 series adjustable column formwork are used in the concrete pouring of square or rectangle column. The largest column dimension is 1050x1050mm and 750x750mm. Combined the two together, the rectangle column can be done,the largest dimension is 1050x750mm.

5.Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Steel Frame Formwork GK120 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Case Study of Aluminum Alloy Formwork

- Aluminum alloy template lighter than the steel template, the use of fast assembly and disassembly system, moving components, lightweight and flexible, greatly reducing the amount of artificial, easy construction management. Aluminum alloy template is one of the most advanced templates, the construction company image is good. Design advanced early demolition system, to speed up the construction progress.

Send your message to us

Aluminum-frame Formwork for Concrete Processing

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords