Economical Plastic Formwork for Rectangle Square Column Panels Modular Shuttering Panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Plastic Formwork Description

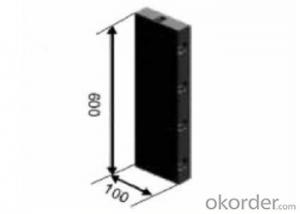

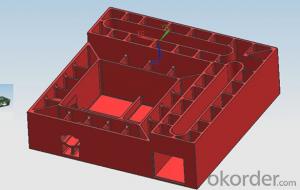

Column panel is a modular shuttering panel, made of high impact resistant PP plastic, for reinforced concrete columns, pile caps and walls.

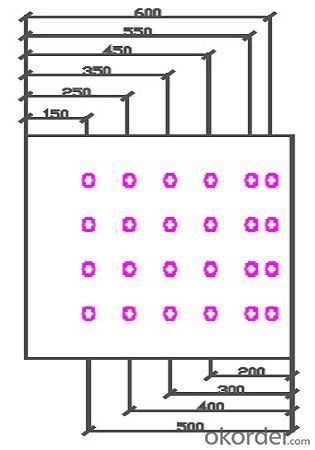

The panels are engineered to interconnect orthogonally in different positions, creating a “star”-shaped formwork of variable size.

The column panels are interconnected using the standard nylon locking handles.

Each panel will require 9 handles.

The forming face has 6 parallel rows of fixing holes to allow the orthogonal connection of the panels in a “star” shape.

The rows are placed at a distance of 100/50 mm the one from the other, allowing the forming of square and/or rectangular columns with side of 150 to 600 mm.

There is a series of holes in the middle of the panels for the passage of tie rods.

The position of the holes is asymmetric to avoid conflict between crossing tie rods.

All unused holes are closed with plugs.

2. Main Features of Plastic Formwork

- Easy Set Up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree.

The panels have rib on the back, which makes the system need not traditional wood blocks and nails.

The panels have holes to fit tie rod, guarantee the strength of the whole system.

- Strength

The material of modular formwork is PC ABS mixed with special glass fibers which enable panels to hold high pressures.

- Environment Friendly.

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

- Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water.

The surface of the wall which built by modular formwork is smooth, can be left without rework

We can special design according to any requirements.

3. Plastic Formwork Size

4. Plastic Formwork Images

5. FAQ of Plastic Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Pvc plate deformation are: physical deformation and chemical deformation.A physical deformation, the cause:???? High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems???? Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the rootTwo chemical deformation: mainly the molecular structure of raw materials change.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- To be honest, not very good. The Temporary use can be

- Q: Types of building templates? What is the water template?

- With the development of the economy, the emergence of new materials in the building materials industry, the increasing number of types of building classification, there are four types of building templates

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- With pliers slowly pull, or spray gun spray.

- Q: Plastic building template where there is an urgent need to solve

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

Economical Plastic Formwork for Rectangle Square Column Panels Modular Shuttering Panel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords