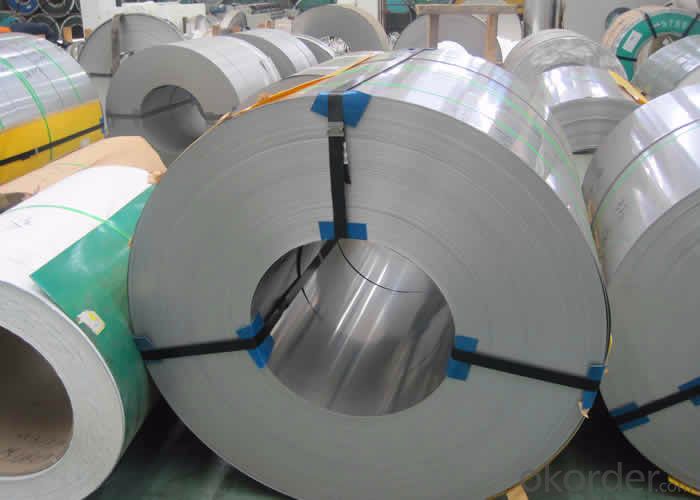

Stainless Steel Coil 201 Hot Rolled Narrow Coil J3

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil

201 Narrow/Wide Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: Can stainless steel strips be used in electronic applications?

- Stainless steel strips are indeed applicable for electronic purposes. Their exceptional corrosion resistance and mechanical properties render them suitable for a range of electronic components and devices. Connectors, terminals, springs, shields, and enclosures often utilize stainless steel due to its common usage. In electronic circuits, stainless steel strips guarantee dependable performance through their high strength and durability. Moreover, their non-magnetic properties make them an excellent fit for applications that demand minimal disruption to magnetic fields. All in all, stainless steel strips present numerous benefits for electronic use, which explains their popularity in the industry.

- Q: Can stainless steel strips be formed into different shapes?

- Yes, stainless steel strips can be formed into different shapes. Stainless steel is a malleable material that can be easily shaped and manipulated. It can be bent, folded, rolled, or stretched into various forms and configurations. This flexibility allows stainless steel strips to be used in a wide range of applications, such as in the manufacturing of appliances, automotive parts, construction materials, and more. The ability to form stainless steel strips into different shapes makes it a versatile material that can be customized to meet specific design requirements.

- Q: Can stainless steel strips be used in conveyor systems?

- Yes, stainless steel strips can be used in conveyor systems. Stainless steel is known for its durability, corrosion resistance, and high strength, making it suitable for conveying various materials in industries such as food processing, manufacturing, and mining. Stainless steel strips can withstand heavy loads and harsh environments, making them an ideal choice for conveyor applications.

- Q: What are the advantages of using precision rolled 111 stainless steel strips?

- There are several advantages of using precision rolled 111 stainless steel strips. Firstly, precision rolling ensures consistent thickness and width throughout the strips, resulting in uniform and reliable products. This uniformity is crucial in applications where precise measurements are required, such as in the manufacturing of electronic components or precision instruments. Secondly, 111 stainless steel is known for its excellent corrosion resistance. This makes it a highly suitable choice for applications where the strips are exposed to harsh environments, chemicals, or moisture. The resistance to corrosion helps to extend the lifespan of the strips, reducing the need for frequent replacements and maintenance. Another advantage of using precision rolled 111 stainless steel strips is their high strength-to-weight ratio. Despite being relatively lightweight, these strips offer exceptional strength, making them suitable for applications where strength and durability are essential. This characteristic is particularly beneficial in the aerospace, automotive, and construction industries, where weight reduction is crucial for achieving fuel efficiency and structural integrity. Furthermore, precision rolled 111 stainless steel strips exhibit excellent formability. This allows them to be easily shaped and molded into various configurations, making them versatile for a wide range of applications. Whether it's for decorative purposes or functional components, these strips can be bent, stamped, or formed to meet specific design requirements. Lastly, precision rolled 111 stainless steel strips are known for their aesthetic appeal. The smooth surface finish and lustrous appearance make them highly desirable for decorative applications, such as architectural accents, jewelry, or kitchenware. The strips can be polished or brushed to achieve different finishes, offering versatility in design options. In summary, the advantages of using precision rolled 111 stainless steel strips include consistent thickness and width, excellent corrosion resistance, high strength-to-weight ratio, exceptional formability, and aesthetic appeal. These qualities make them a preferred choice in various industries, ensuring reliable performance and longevity for the intended applications.

- Q: How do stainless steel strips resist intergranular corrosion in welding?

- Stainless steel strips resist intergranular corrosion in welding due to the presence of chromium in their composition. Chromium forms a protective oxide layer on the surface of the steel, preventing corrosive agents from attacking the grain boundaries. This oxide layer acts as a barrier, ensuring the integrity and durability of the stainless steel strips even in harsh welding environments.

- Q: Can stainless steel strips be used in the nuclear industry?

- The nuclear industry finds stainless steel strips highly useful. Its exceptional corrosion resistance and mechanical properties make stainless steel a popular choice for various applications in this industry. Stainless steel is commonly employed in the construction of nuclear power plants, nuclear reactors, and related equipment. In the nuclear industry, stainless steel strips serve numerous purposes. For example, they play a crucial role in fabricating nuclear fuel assemblies - essential components of nuclear reactors. These fuel assemblies house fuel rods that produce heat through nuclear fission. The use of stainless steel strips ensures the structural integrity and safety of the fuel assemblies by providing necessary support. Furthermore, stainless steel strips are utilized in constructing containment vessels and pressure vessels in nuclear plants. These vessels are responsible for containing radioactive materials and ensuring the safety of personnel and the surrounding environment. Stainless steel's resistance to corrosion and ability to withstand high temperatures make it an ideal choice for these critical applications. Moreover, stainless steel strips are employed in manufacturing various components like piping systems, heat exchangers, valves, and pumps in nuclear facilities. These components require materials that can endure harsh operating conditions, including high temperatures, radiation exposure, and corrosive environments. Stainless steel's durability and resistance to corrosion make it a reliable material for these applications. In conclusion, the nuclear industry extensively relies on stainless steel strips due to their exceptional properties, making them suitable for diverse applications. The industry depends on stainless steel's corrosion resistance, mechanical strength, and high-temperature tolerance to ensure the safety and efficiency of nuclear power generation.

- Q: What are the common weight tolerances for stainless steel strips?

- The common weight tolerances for stainless steel strips vary depending on the specific grade and thickness of the material. However, in general, stainless steel strips typically have weight tolerances ranging from +/- 5% to +/- 10%. This means that the actual weight of the strip may deviate by up to 5% or 10% from the specified weight. These tolerances are necessary due to the inherent variability in the manufacturing process and the possibility of slight variations in the thickness and density of the stainless steel. It is important to note that more precise weight tolerances may be achievable for custom-made or specialized stainless steel strips, depending on the manufacturer's capabilities and the customer's requirements.

- Q: What are the different surface treatments for stainless steel strips?

- Stainless steel strips come with a variety of surface treatments, each serving a specific purpose and offering unique advantages. The following are some of the most commonly used surface treatments: 1. Mill Finish: This is the untreated surface of stainless steel, which has a smooth, slightly reflective appearance. It is the standard finish that comes directly from the mill and is suitable for applications where aesthetics are not the main concern. 2. Polished Finish: This treatment involves polishing the stainless steel surface to achieve a high gloss or mirror-like finish. It enhances the material's appearance and is often used for decorative purposes, such as in architecture or interior design. 3. Brushed Finish: Also referred to as a satin finish, this treatment involves brushing the stainless steel surface with fine abrasive materials in one direction. It creates a textured, matte look that is resistant to fingerprints and scratches. Brushed finish is commonly used in appliances, kitchen equipment, and automotive trims. 4. Bead Blasted Finish: In this treatment, small glass beads are blasted onto the stainless steel surface at high pressure, resulting in a uniform, non-reflective finish. It provides a unique, textured appearance and is often used in industrial or architectural applications where a matte, low-glare surface is desired. 5. PVD Coating: Physical Vapor Deposition (PVD) is a process that applies a thin layer of coating to the stainless steel surface using vacuum deposition techniques. This coating can offer various colors, such as gold, black, or bronze, as well as enhanced durability and corrosion resistance. 6. Electropolishing: This treatment involves immersing the stainless steel strip in an electrolyte solution and applying an electrical current to remove a thin layer of material from the surface. It results in a smooth, shiny finish with improved resistance to corrosion and bacterial growth. Electropolishing is commonly used in medical, pharmaceutical, and food processing equipment. To ensure the most suitable surface treatment for your stainless steel strips, it is essential to consider the specific requirements of your application and seek advice from a stainless steel supplier or surface treatment specialist.

- Q: How do stainless steel strips handle exposure to acids?

- The high resistance of stainless steel strips to the corrosive effects of acids is attributed to the presence of chromium in their composition. This chromium forms a protective oxide layer on the metal's surface, acting as a barrier against direct contact with the acid and reducing the risk of corrosion. In addition to chromium, stainless steel also contains other alloying elements like nickel and molybdenum, which further enhance its acid resistance. However, it is important to consider that the performance of stainless steel strips may vary depending on the type and concentration of acid they are exposed to. Certain aggressive acids can still cause some degree of corrosion, particularly at elevated temperatures or with prolonged exposure. Therefore, it is recommended to seek advice from a corrosion specialist or consult specific guidelines to ensure the appropriate grade of stainless steel is chosen for a particular acid exposure application.

- Q: Can 111 stainless steel strips be coated with anti-galling coatings?

- Yes, 111 stainless steel strips can be coated with anti-galling coatings.

Send your message to us

Stainless Steel Coil 201 Hot Rolled Narrow Coil J3

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords