Stainless Steel Plate/Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 30000TON PER MONTH m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

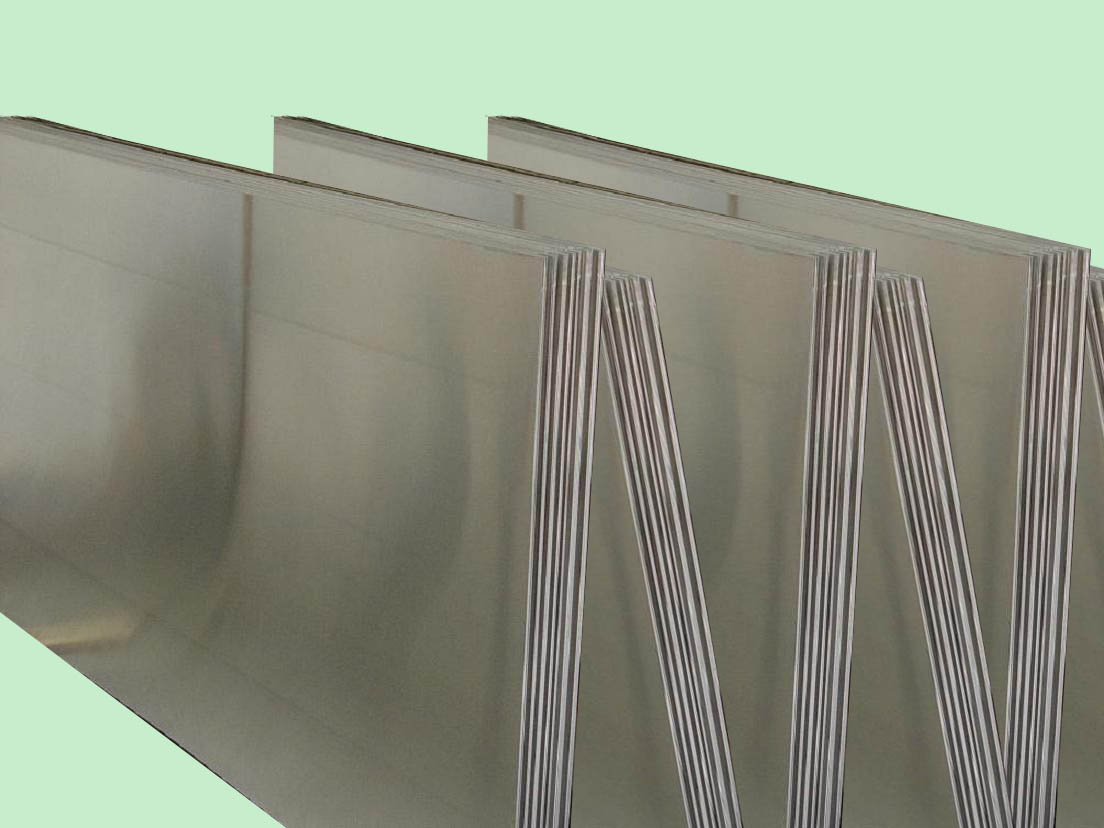

cold/hot rolled stainless steel plate, sheet

Standard: ASTM/AISI/JIS/EN

Grade: 201,202,304,304L,316, 310, 409,410,430 etc…

Thickness: 0.2 - 200mm

Width: 600, 1000, 1219, 1500mm,

width and length could be customized

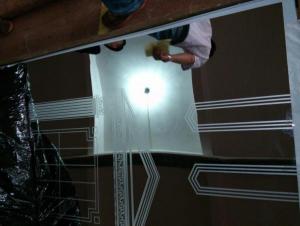

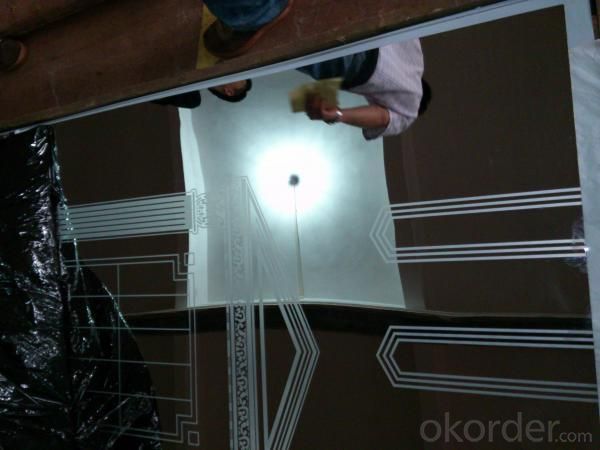

Surface finish: No.1, 2B, BA, mirror, hair line, etc...

- Q: How do you measure the hardness of a stainless steel strip?

- The hardness of a stainless steel strip can be measured using various methods, but the most commonly used method is the Rockwell hardness test. This test involves using a diamond cone or a hardened steel ball indenter to penetrate the surface of the strip under a specific load. The depth of indentation is then measured, and a hardness value is determined based on the Rockwell scale. To conduct the Rockwell hardness test, the stainless steel strip is securely placed on a testing machine with a flat and smooth surface. The indenter is then brought into contact with the surface of the strip, and a preliminary load is applied to set the initial position of the indenter. Once the preliminary load is set, the final load is applied, and the indenter penetrates the surface to a certain depth. After removing the load, the resulting indentation is measured using a microscope or an optical measuring device. The hardness value is determined by taking the difference between the depth of penetration under the final load and the depth of penetration under the preliminary load. This value is then converted to a Rockwell hardness number using a chart or a digital display on the testing machine. It is worth mentioning that the Rockwell hardness test provides a measure of the material's resistance to indentation, which is an indirect indication of its mechanical properties such as strength and toughness. Other methods, such as the Vickers or Brinell hardness tests, can also be used to measure the hardness of stainless steel strips, depending on the specific requirements and characteristics of the material.

- Q: Can stainless steel strips be used in chemical storage applications?

- Yes, stainless steel strips can be used in chemical storage applications. Stainless steel is highly resistant to corrosion and can withstand exposure to various chemicals, making it an excellent choice for storing chemicals safely. Additionally, stainless steel is durable, easy to clean, and has a high strength-to-weight ratio, making it suitable for storing and transporting chemicals in different environments. Its non-reactive nature ensures that the stored chemicals remain uncontaminated, and stainless steel's ability to withstand high temperatures further enhances its suitability for chemical storage applications.

- Q: How do stainless steel strips resist embrittlement in high-temperature applications?

- The exceptional resistance to embrittlement in high-temperature applications is a well-known characteristic of stainless steel strips. This resistance can primarily be attributed to the unique composition and microstructure of stainless steel. Stainless steel, being an alloy, contains a significant amount of chromium, typically ranging from 10-30%. The presence of chromium in stainless steel plays a crucial role in its ability to resist embrittlement. One of the reasons for this is that chromium forms a passive oxide layer on the surface of stainless steel, known as chromium oxide or Cr2O3. This oxide layer acts as a protective barrier, preventing the diffusion of harmful elements and reducing the vulnerability to embrittlement. In high-temperature environments, stainless steel strips are able to retain their resistance to embrittlement due to the stability of the chromium oxide layer. Even at elevated temperatures, this layer remains intact, providing a continuous barrier against the corrosive and embrittling effects of the surrounding environment. Moreover, stainless steel also contains other alloying elements such as nickel and molybdenum, which contribute to its strength at high temperatures and its resistance to embrittlement. These elements enhance the stability of the microstructure, preventing the formation of brittle phases and maintaining the ductility of the stainless steel strips. The fine-grained microstructure of stainless steel is another crucial factor in its resistance to embrittlement. The presence of fine grains inhibits the propagation of cracks and reduces overall susceptibility to fracture, even at high temperatures. Additionally, the presence of carbides, nitrides, or other precipitates within the stainless steel matrix can help immobilize dislocations and prevent their movement, further enhancing the resistance to embrittlement. In conclusion, the resistance of stainless steel strips to embrittlement in high-temperature applications is attributed to the protective chromium oxide layer, the presence of alloying elements, the stability of the microstructure, and the inhibiting effects of precipitates. These factors work together to ensure that stainless steel maintains its strength, ductility, and resistance to fracture, even under extreme temperature conditions.

- Q: What are the common uses of stainless steel strips in the automotive engine components?

- Due to their unique properties and advantages, stainless steel strips find widespread use in various engine components within the automotive industry. The following are some common applications of stainless steel strips in automotive engine components: 1. Exhaust Systems: Stainless steel strips are extensively employed in exhaust systems owing to their ability to withstand high temperatures and resist corrosion. By enduring the extreme heat and corrosive gases emitted by the engine, they ensure the exhaust system's durability and longevity. 2. Fuel Injection Systems: Stainless steel strips are utilized in fuel injection systems, particularly in the manufacturing of fuel rails and fuel lines. The corrosion resistance of stainless steel guarantees uncontaminated fuel and prevents any leakages, thereby enhancing the system's overall efficiency and reliability. 3. Heat Shields: The production of heat shields relies on the usage of stainless steel strips, as they protect sensitive engine components from excessive heat. With the high temperature resistance of stainless steel, the heat shield can effectively dissipate or reflect heat, preventing any harm to nearby components. 4. Engine Mounts and Brackets: The fabrication of engine mounts and brackets often involves the use of stainless steel strips due to their strength and durability. These strips provide structural support and ensure the secure attachment of various engine components, thereby enhancing the engine's overall stability and performance. 5. Valve Components: Valve components, such as valve springs and valve retainers, are commonly manufactured using stainless steel strips. The high strength and corrosion resistance of stainless steel enable these components to withstand the engine's high pressures and temperatures, ensuring efficient and seamless valve operation. In conclusion, stainless steel strips are of paramount importance in automotive engine components, as they provide durability, corrosion resistance, high temperature resistance, and structural support. These properties make them an ideal choice for various applications, thereby contributing to the performance, efficiency, and longevity of automotive engines.

- Q: What are the recommended cleaning agents for 111 stainless steel strips?

- Depending on the specific requirements and conditions of the stainless steel strips, the choice of cleaning agents recommended for 111 stainless steel strips may vary. However, there are some commonly suggested options for cleaning stainless steel, such as mild soap or detergent, non-abrasive cleaners, and specialized stainless steel cleaners. For regular cleaning of stainless steel strips, it is usually sufficient to use a mild soap or detergent along with warm water. This solution can be gently applied to the surface using a soft cloth or sponge. It is crucial to avoid using abrasive cleaners that contain bleach or chlorine, as they can harm the finish of the stainless steel. In case of tougher stains or stubborn dirt, non-abrasive cleaners specifically designed for stainless steel can be utilized. These cleaners are typically available in spray or liquid form and can be applied to the surface and wiped off with a clean cloth. It is essential to carefully follow the instructions provided by the manufacturer of the specific cleaner being used. Furthermore, there are specialized stainless steel cleaners available in the market that are formulated to eliminate fingerprints, smudges, and other marks from stainless steel surfaces. These cleaners are often available as sprays or wipes and can be used as needed to maintain the appearance of the stainless steel strips. It is always advisable to test any cleaning agent on a small and inconspicuous area of the stainless steel strips before applying it to the entire surface. This precaution ensures that the cleaning agent does not cause any damage or discoloration to the stainless steel. Additionally, it is important to adhere to the manufacturer's instructions for both the cleaning agents and the stainless steel strips to achieve optimal cleaning results and prevent any surface damage.

- Q: How do stainless steel strips perform in high humidity environments?

- Stainless steel strips perform exceptionally well in high humidity environments. Due to their inherent corrosion-resistant properties, stainless steel strips are highly resistant to rust and oxidation, making them ideal for use in humid conditions. The chromium content in stainless steel forms a protective layer on the surface, preventing moisture from penetrating and causing damage. This protective layer, known as the passive film, is self-repairing, ensuring long-term durability even in high humidity environments. Additionally, stainless steel strips are highly resistant to pitting and crevice corrosion, which can be common in humid conditions. Therefore, stainless steel strips are a reliable and preferred choice for various applications such as in marine environments, chemical processing plants, and outdoor structures where high humidity is prevalent.

- Q: Can stainless steel strips be used for automotive exhaust systems?

- Yes, stainless steel strips can be used for automotive exhaust systems. Stainless steel is highly resistant to corrosion, can withstand high temperatures, and has excellent durability, making it an ideal material for exhaust systems.

- Q: Are stainless steel strips suitable for food processing applications?

- Yes, stainless steel strips are suitable for food processing applications. Stainless steel is known for its resistance to corrosion, durability, and hygiene properties, making it a popular choice in the food industry. It does not react with food or alter its taste, ensuring product integrity. Additionally, stainless steel strips can be easily cleaned and sanitized, meeting the strict hygiene standards required in food processing.

- Q: Can stainless steel strips be used in the production of electrical enclosures?

- Yes, stainless steel strips can be used in the production of electrical enclosures. Stainless steel is a versatile and durable material that is widely used in various industries, including electrical engineering. It offers excellent corrosion resistance, high strength, and heat resistance, making it suitable for enclosing electrical components and protecting them from external elements. Stainless steel strips can be formed, cut, and welded into the desired shapes and sizes to create enclosures that meet the specific requirements of electrical applications. Additionally, stainless steel has good electrical conductivity, which is crucial for ensuring proper grounding and electromagnetic compatibility within the enclosure. Therefore, utilizing stainless steel strips in the production of electrical enclosures is a common and reliable choice.

- Q: Can stainless steel strips be used for decorative screens?

- Indeed, decorative screens can utilize stainless steel strips. Possessing durability and aesthetic charm, stainless steel is a versatile material that enjoys popularity in diverse applications, including decorative screens. By cutting and shaping the strips, one can fashion various patterns or designs, enabling the creation of customized and innovative screen options. Furthermore, stainless steel's resistance to corrosion and ability to endure outdoor conditions make it suitable for both indoor and outdoor decorative screens. Whether the objective is privacy, partitioning, or enhancing the visual allure of a space, stainless steel strips prove to be an outstanding choice for fashioning decorative screens.

Our company can provide stainless steel horizontal shear, slitting, CNC plasma cutting, sanding, 8K, oil mill, anti-fingerprint, embossed, red flowers, spare parts and other supporting services, and provide customized integration services to meet all customer needs.we have more than 10 years history, and have long maintained good cooperative relations with well-known domestic partners.

1. Manufacturer Overview

| Location | Wuxi,China |

| Year Established | 2000 |

| Annual Output Value | Above US$16 Million |

| Main Markets | Chinese, Europe,South Africa |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Plate/Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 30000TON PER MONTH m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords