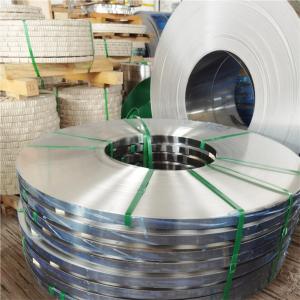

410S Heat treated stainless steel strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 3000 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

410S Heat treated stainless steel strip

Heat treated steel strip is a type of steel strip product that is processed through specific techniques to improve its performance.

Heat treated spring steel strip is a type of strip spring steel that is processed through a heat treatment process. It has the characteristics of high strength, good fatigue resistance, and low hydrogen embrittlement. In addition, the chemical composition of the steel strip is also very good, with high hardness and elasticity.

Heat treated steel strips are widely used in various industrial fields, including but not limited to:

Spring steel strip: such as 65Mn spring steel strip, commonly used for making springs and other components that require high elasticity.

Tool material: such as 440C stainless steel strip, commonly used for making cutting tools and wear-resistant parts.

Other industrial applications, such as conveyor belts, bundling goods, etc., meet the needs of different industrial sectors.

Specification: 0.1mm-3.0mm customizable

Processing technology: Cold rolling, hot rolling

Product Surface: Blue, Black, Silver White

Processing services: deep processing (stamping, bending, etc.), rough processing (cutting, slitting, etc.)

Delivery status: soft, semi hard, fully hard

- Q: What is the difference between hot rolled and cold rolled stainless steel strips?

- Hot rolled stainless steel strips are produced by passing the steel through a set of rollers at a high temperature, typically above 1,000 degrees Celsius. This process makes the steel more malleable and easier to form into various shapes. Hot rolled strips typically have a rough surface finish and can have a slightly rounded edge. On the other hand, cold rolled stainless steel strips are produced by passing the steel through a set of rollers at room temperature or slightly below. This process helps to improve the surface finish and dimensional accuracy of the strips. Cold rolled strips have a smoother surface finish and sharper edges compared to hot rolled strips. Another key difference between hot rolled and cold rolled stainless steel strips is the mechanical properties. Hot rolled strips tend to have a higher yield strength and are generally more ductile, making them suitable for applications that require shaping or bending. Cold rolled strips, on the other hand, have a higher tensile strength and are generally harder, making them ideal for applications that require strength and durability. In terms of cost, hot rolled stainless steel strips are generally cheaper to produce compared to cold rolled strips. However, due to the additional processing steps involved in cold rolling, the cost of cold rolled strips is often higher. Overall, the choice between hot rolled and cold rolled stainless steel strips depends on the specific requirements of the application. Hot rolled strips are suitable for applications where shaping or bending is necessary, while cold rolled strips are preferred for applications that require strength and a smooth surface finish.

- Q: How do stainless steel strips perform in cryogenic environments?

- Stainless steel strips are known for their exceptional performance in cryogenic environments. Due to their unique composition and properties, stainless steel strips exhibit excellent resistance to extreme low temperatures. At cryogenic temperatures, stainless steel strips retain their strength, toughness, and corrosion resistance, making them highly suitable for use in various applications. The inherent stability of stainless steel allows it to maintain its mechanical properties even under extreme cold conditions, preventing brittleness or cracking that can compromise its structural integrity. Stainless steel's resistance to corrosion is particularly advantageous in cryogenic environments, where moisture and other corrosive elements may be present. The passive oxide layer formed on the surface of stainless steel helps protect it from chemical reactions and oxidation, ensuring durability and longevity in cryogenic applications. Additionally, stainless steel strips offer good thermal conductivity, allowing for efficient heat transfer in cryogenic systems. This can be beneficial in applications such as cryogenic storage tanks, where maintaining the temperature of the stored materials is crucial. Overall, stainless steel strips demonstrate excellent performance in cryogenic environments, combining strength, toughness, corrosion resistance, and thermal conductivity. These properties make stainless steel a preferred choice in various industries, including aerospace, energy, medical, and research, where cryogenic conditions are prevalent.

- Q: Can stainless steel strips be used in the manufacturing of kitchen appliances?

- Yes, stainless steel strips can be used in the manufacturing of kitchen appliances. Stainless steel is a popular choice for kitchen appliances due to its durability, resistance to corrosion, and ease of cleaning. Stainless steel strips can be utilized to create various components and surfaces in kitchen appliances, ensuring a sleek and modern look while providing excellent functionality.

- Q: Can stainless steel strips be used in packaging machinery?

- Packaging machinery can utilize stainless steel strips effectively. Stainless steel, a versatile and long-lasting material, finds widespread use in machinery and equipment, including packaging machinery. Its exceptional resistance to corrosion, high temperature, and wear make it well-suited for diverse packaging applications. When integrated into packaging machinery, stainless steel strips enable tasks such as cutting, sealing, and forming packaging materials. Moreover, stainless steel's sleek surface and convenient cleaning properties make it an optimal choice for upholding hygiene and preventing contamination during the packaging process. In summary, stainless steel strips present a dependable and efficient solution for utilization in packaging machinery.

- Q: What is the maximum temperature that stainless steel strips can withstand?

- The maximum temperature that stainless steel strips can withstand depends on the specific grade of stainless steel. However, most stainless steel alloys can withstand temperatures up to 1500 degrees Fahrenheit (815 degrees Celsius) before significant structural changes occur.

- Q: Can stainless steel strips be used in watchmaking?

- Yes, stainless steel strips can be used in watchmaking. Stainless steel is commonly used in watchmaking due to its durability, corrosion resistance, and aesthetic appeal. It is often used for watch cases, bands, and other components.

- Q: Are stainless steel strips suitable for architectural applications?

- Yes, stainless steel strips are suitable for architectural applications. They are highly durable, corrosion-resistant, and have an aesthetically pleasing appearance, making them ideal for various architectural purposes such as cladding, decorative elements, and structural components.

- Q: Can stainless steel strips be used for medical implants?

- Yes, stainless steel strips can be used for medical implants. Stainless steel is a commonly used material in the medical field due to its excellent mechanical properties, corrosion resistance, and biocompatibility. It can be easily shaped into strips or other desired forms to meet the specific requirements of medical implants. Stainless steel strips are often used in orthopedic implants such as plates, screws, and wires, as well as in cardiovascular implants like stents and pacemakers. The material's ability to withstand sterilization processes and its long-term durability make it a suitable choice for medical implants. However, it is important to note that the specific grade of stainless steel used, as well as the design and surface finish of the strips, should be carefully considered to ensure compatibility with the human body and minimize the risk of adverse reactions or complications.

- Q: Are stainless steel strips suitable for appliance handles?

- Yes, stainless steel strips are highly suitable for appliance handles. Stainless steel is known for its durability, corrosion resistance, and sleek appearance, making it an ideal material for handles that are regularly used and exposed to moisture. Moreover, stainless steel can easily be cleaned and maintained, ensuring the longevity and cleanliness of the appliance handles.

- Q: What are the common thickness and width combinations for stainless steel strips?

- Depending on the specific applications and industry requirements, the common thickness and width combinations for stainless steel strips can vary. However, there are some standard thickness and width combinations that are frequently used. Thin stainless steel strips usually have a thickness ranging from 0.01mm to 3mm, and the width typically falls between 5mm and 500mm. These thin strips are commonly found in industries such as electronics, automotive, and medical. Medium thickness stainless steel strips, on the other hand, can have a thickness ranging from 3mm to 20mm, with a width that can vary between 100mm and 1500mm. These medium thickness strips are often utilized in applications such as construction, architecture, and machinery manufacturing. Thicker stainless steel strips, which are commonly used in heavy industries like oil and gas, petrochemical, and shipbuilding, can have a thickness exceeding 20mm and a width wider than 1500mm. It should be noted that these thickness and width combinations are not exhaustive and can be adjusted based on the specific requirements of each project. Manufacturers and suppliers of stainless steel strips are often able to customize the thickness and width according to the customer's needs and specifications.

Send your message to us

410S Heat treated stainless steel strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 3000 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches