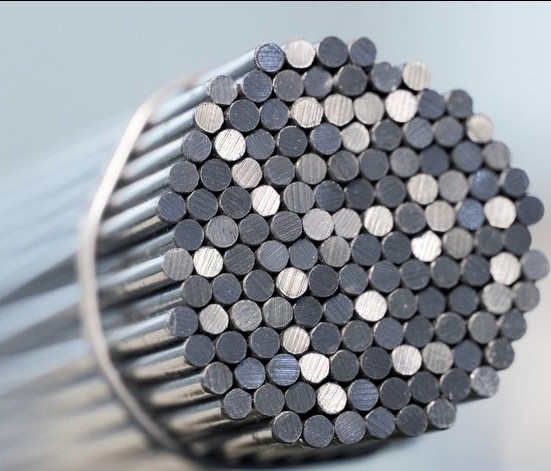

High Quality Stainless Steel Profile Pipe with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of High Quality Stainless Steel Profile Pipe:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of High Quality Stainless Steel Profile Pipe: 25 Tons/20FCL.

Grade of High Quality Stainless Steel Profile Pipe: 201, 306, 316 Etc.

Delivery Time of High Quality Stainless Steel Profile Pipe: 20 days Per Container.

Application of High Quality Stainless Steel Profile Pipe:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Packaging & Delivery of High Quality Stainless Steel Profile Pipe

| Packaging Detail: | standard seaworthy export package or as customers required |

| Delivery Detail: | Normally according to the order quantity or upon negotiation. |

Specification of High Quality Stainless Steel Profile Pipe:

1).Standard : GB,ASTM,AISI,JIS,SUS,EN

2).Material : 304,304L,304N,304LN,301,305,309S,310S,316,316L,316N,316LN,316Ti,

317,317L,321,347,201,202

3).Outside Diameter: From 4mm to 2500mm(1/8''inch-120''inch)

4).Wall Thickness : Sch5S-SchXXS(1mm-150mm)

5). Length : 3m,4m,5.8m,6m,12m or as required

6). Chemical composition:

7).Surface :Annealing ,polish,pickling,bright ,sand blast ,etc

8).Packing: 1.plastic cap with both ends 2.steel strip bundled package3.wooden case,wooden

pallet package4.container or bulk 5. as customers' requestment

9).Application:petroleum ,chemical industry,bolier ,heat exchange,high temperature

resistant transmission fluid pipe in power station,ship with pressure pipe,construction

and so on

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for both High Quality Stainless Steel Profile Pipe are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE High Quality Stainless Steel Profile Pipe samples are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- To prevent galvanic corrosion on stainless steel sheets, you can consider a few measures. Firstly, ensure that you use compatible metals when in contact with stainless steel to avoid creating a galvanic couple. Additionally, using insulation or separating materials, such as plastic or rubber gaskets, between dissimilar metals can help prevent galvanic corrosion. Regular cleaning and maintenance of stainless steel surfaces can also mitigate the risk of corrosion. Lastly, applying protective coatings or using corrosion inhibitors can provide an extra layer of defense against galvanic corrosion on stainless steel sheets.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties and versatility. Some of the most common uses include: 1. Construction: Stainless steel sheets are extensively used in the construction industry for roofing, cladding, and facades. They offer excellent durability, corrosion resistance, and a modern aesthetic appeal. 2. Automotive: Stainless steel sheets find applications in the automotive industry for manufacturing various components such as exhaust systems, grilles, trims, and decorative elements. Their resistance to heat, corrosion, and impact makes them ideal for these purposes. 3. Kitchen appliances: Stainless steel sheets are commonly used in the manufacturing of kitchen appliances like refrigerators, ovens, dishwashers, and sinks. Their hygienic properties, resistance to stains, and easy maintenance make them a popular choice for these applications. 4. Food processing: Stainless steel sheets are widely used in the food processing industry due to their non-reactive nature and ease of cleaning. They are used for making equipment such as storage tanks, conveyor systems, work surfaces, and food preparation tables. 5. Medical equipment: Stainless steel sheets are crucial in the manufacturing of medical equipment and devices. They are used for surgical instruments, dental tools, implantable devices, and hospital furniture due to their biocompatibility, corrosion resistance, and ease of sterilization. 6. Aerospace: Stainless steel sheets are utilized in the aerospace industry for constructing aircraft components like fuselage frames, engine parts, and landing gear. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance make them suitable for these demanding applications. 7. Energy and power generation: Stainless steel sheets are commonly used in power plants, oil refineries, and chemical processing plants for constructing equipment like heat exchangers, boilers, and storage tanks. Their ability to withstand high temperatures, pressure, and corrosive environments is essential in these industries. 8. Decorative purposes: Stainless steel sheets are also used for decorative purposes in architecture and interior design. They can be used to create unique and modern finishes on walls, ceilings, furniture, and decorative panels. Overall, stainless steel sheets are a versatile material used in various industries due to their exceptional properties like corrosion resistance, durability, hygienic properties, and aesthetic appeal.

- Q: What are the different types of stainless steel sheet thickness tolerances?

- The different types of stainless steel sheet thickness tolerances include standard, tight, and extra tight tolerances. Standard tolerances allow for slight variations in thickness, tight tolerances have lower permissible deviations, and extra tight tolerances have even smaller allowable variations in thickness.

- Q: What are the different types of stainless steel sheet surface finishes available?

- Some of the different types of stainless steel sheet surface finishes available include: 1. No.1 Finish: This is a rough, dull surface finish with visible grain lines. 2. No.2B Finish: It has a smooth, bright finish that is commonly used for appliances and architectural applications. 3. No.4 Finish: This finish has a brushed appearance with fine grain lines and is often used in decorative applications. 4. No.8 Mirror Finish: It provides a highly reflective surface that is used for decorative purposes. 5. Satin Finish: It has a smooth, silky appearance with low reflectivity and is commonly used in architectural and decorative applications. 6. Brushed Finish: This finish has a consistent linear grain pattern created by brushing the surface with abrasive materials. 7. Embossed Finish: It features raised patterns or textures on the surface, providing a decorative and tactile effect. 8. Bead Blast Finish: It creates a uniform, matte surface texture by blasting stainless steel sheets with fine glass beads. 9. Etched Finish: This finish involves chemically etching the surface to create patterns or designs. 10. Colored Finish: Stainless steel sheets can be coated or treated to achieve various colors and finishes, allowing for customization and aesthetic appeal.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Yes, stainless steel sheets can be used for oil and gas pipelines. Stainless steel is commonly used in the oil and gas industry due to its excellent corrosion resistance properties. It can withstand the harsh conditions of transportation and storage of oil and gas, including high-pressure, high-temperature, and corrosive environments. Stainless steel sheets are often utilized to fabricate pipeline components such as pipes, fittings, and flanges, as they offer durability, strength, and resistance to corrosion, which helps to prevent leaks and maintain the integrity of the pipeline.

- Q: What is the price range for stainless steel sheets?

- The price range for stainless steel sheets can vary depending on a few factors such as the thickness, size, and grade of the stainless steel. Generally, the price range for stainless steel sheets starts at around $30 per square foot for thinner sheets and can go up to $150 per square foot for thicker or higher-grade sheets. It's important to note that prices can also be influenced by market conditions and supplier pricing policies, so it's always a good idea to compare prices from different suppliers before making a purchase.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The quality and consistency of stainless steel sheets are ensured by several common manufacturing standards. One widely recognized standard is the ASTM International standard, formerly known as the American Society for Testing and Materials. Specifically, the ASTM A240 standard specifies the chemical composition, mechanical properties, and other relevant characteristics of stainless steel sheets. Another important standard is the EN standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers dimensions, tolerances, surface finishes, and more. Different countries also have their own national standards. For example, in Japan, stainless steel sheets are classified under specifications such as JIS G4304 and JIS G4305, which are part of the Japanese Industrial Standards (JIS). These standards define the chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in manufacturing, and their properties are defined by the AISI. Manufacturers and suppliers must adhere to these standards to ensure that stainless steel sheets meet quality requirements and can be reliably used in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across industries.

- Q: Are stainless steel sheets fire resistant?

- The fire resistance properties of stainless steel sheets are exceptional. With their high melting point and low thermal conductivity, stainless steel can endure prolonged exposure to high temperatures without experiencing significant structural alterations or losing strength. As a result, stainless steel sheets possess remarkable resistance to fire and heat harm. Furthermore, stainless steel does not emit toxic fumes when exposed to fire, further enhancing its safety in environments prone to fires. Consequently, stainless steel sheets are frequently employed in situations where fire resistance is of utmost importance, such as the construction of fire doors, fire escapes, and fire-resistant enclosures.

- Q: What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can vary depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability compared to other types of metals such as carbon steel or aluminum. This is mainly due to its higher strength, hardness, and work-hardening characteristics. Stainless steel has a tendency to work-harden during machining, leading to increased cutting forces and tool wear. It also has a lower thermal conductivity, which can result in higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and difficult-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to improve the machinability of stainless steel. For instance, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can exhibit varying machinability. Austenitic stainless steels, such as 304 and 316, are generally more difficult to machine compared to ferritic or martensitic stainless steels. This is due to their higher nickel and chromium content, which contribute to their superior corrosion resistance but also make them harder to machine. Overall, while stainless steel sheets may present some challenges in machining, with the right tools, techniques, and experience, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

Send your message to us

High Quality Stainless Steel Profile Pipe with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords