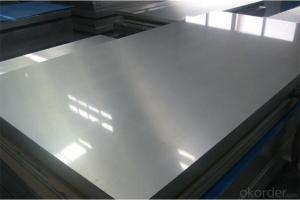

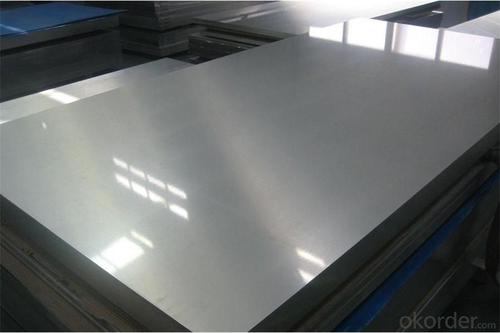

Zinc Coating Galvanized Sheets/ Coil/ GI Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

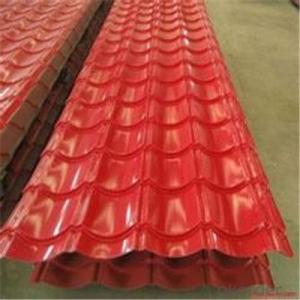

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

- Q: What are the different types of surface treatments available for steel sheets?

- Steel sheets have a variety of surface treatments available, each with specific purposes and unique advantages. 1. Hot-dip galvanizing: To prevent corrosion, steel sheets are immersed in molten zinc, forming a protective coating. This method offers excellent durability and corrosion resistance. 2. Electro-galvanizing: A thin, uniform layer of zinc is deposited onto the steel sheets through an electrochemical process. This treatment provides good corrosion protection and is often used for decorative purposes. 3. Powder coating: Dry powder is applied onto the steel sheets and then cured with heat. This treatment offers a durable and attractive finish while protecting against corrosion, UV rays, and chemicals. 4. Paint coating: Steel sheets can be coated with different types of paints, such as epoxy, polyurethane, and polyester. Paint coatings provide aesthetic appeal and protection against corrosion and weathering. 5. Phosphating: A phosphate coating is applied to enhance corrosion resistance and improve paint adhesion. This treatment is commonly used as a pre-treatment before painting or powder coating. 6. Chromate conversion coating: A thin layer of chromate is applied to enhance corrosion resistance and improve paint adhesion. This treatment is also known as chromating or passivation. 7. Anodizing: While primarily used for aluminum, anodizing can also be applied to steel sheets. This process creates an oxide layer that improves corrosion resistance and provides a decorative finish. 8. Pickling: Steel sheets are immersed in an acidic solution to remove impurities like scale and rust. Pickling leaves the steel sheets with a clean and smooth surface, ready for subsequent treatments. In conclusion, the choice of surface treatment for steel sheets depends on the intended application, desired appearance, and required level of corrosion resistance.

- Q: How do steel sheets compare to other materials like aluminum or plastic?

- Steel sheets offer several advantages over other materials such as aluminum or plastic. Firstly, steel is notably stronger and more durable than both aluminum and plastic. It possesses a higher tensile strength and can withstand significantly greater loads and impacts. As a result, steel sheets are more suitable for applications that demand high strength and structural integrity, like the construction, automotive, and aerospace industries. Secondly, steel exhibits greater resistance to extreme temperatures and fire compared to aluminum or plastic. With a higher melting point, steel sheets are less likely to deform or lose their structural integrity under high temperatures. This characteristic makes them ideal for applications involving exposure to heat or fire, such as industrial furnaces or fire-resistant structures. Moreover, steel sheets offer superior corrosion resistance when compared to aluminum or plastic. Steel can be coated with various protective layers like zinc or paint to prevent rusting and corrosion. Conversely, aluminum is prone to corrosion in specific environments, while plastic may degrade and become brittle over time. Consequently, steel sheets are a more reliable choice in applications where exposure to moisture or corrosive substances is a concern, such as marine environments or chemical processing plants. Lastly, steel sheets are more environmentally friendly than both aluminum and plastic. Steel is a recyclable material that can be reused indefinitely without losing its properties. On the other hand, aluminum recycling requires significantly more energy, and plastic has a known detrimental impact on the environment due to its slow decomposition. Therefore, for those seeking environmentally friendly options, steel sheets, being recyclable and sustainable, are the preferred choice. In conclusion, steel sheets surpass materials like aluminum or plastic in terms of strength, durability, resistance to extreme temperatures and corrosion, as well as being more environmentally friendly. However, the specific choice of material ultimately depends on the application requirements, cost considerations, and other factors.

- Q: Do steel sheets have any magnetic properties?

- Yes, steel sheets can have magnetic properties. The magnetic properties of steel sheets depend on the composition and processing methods used. Some steels, such as carbon steels, are not inherently magnetic, while others, such as stainless steels, can exhibit magnetic behavior.

- Q: How do steel sheets compare to other types of sheet materials?

- Steel sheets have several advantages over other types of sheet materials. Firstly, steel sheets are extremely durable and have a high strength-to-weight ratio, making them suitable for a wide range of applications. They also offer excellent resistance to corrosion, which is a significant advantage in harsh environments. Moreover, steel sheets can withstand high temperatures, making them ideal for applications that involve heat exposure. Additionally, steel sheets are highly versatile and can be easily customized to meet specific requirements. Overall, the superior strength, durability, and versatility of steel sheets make them stand out when compared to other sheet materials.

- Q: Can steel sheets be used for safety barriers or guardrails?

- Safety barriers or guardrails can indeed utilize steel sheets. The construction industry frequently employs steel sheets due to their robustness, durability, and ability to withstand impacts. These sheets can be molded into various forms, allowing for the creation of safety barriers or guardrails that effectively safeguard against accidents. Common applications of steel sheets in this context include road safety barriers, highway guardrails, and industrial safety barriers. Their purpose is to absorb the force of a collision, redirect the vehicle, and prevent it from crossing into oncoming traffic or hazardous zones. Moreover, steel sheets can be galvanized or coated to enhance their resistance to corrosion, making them suitable for outdoor usage in adverse weather conditions. In summary, steel sheets are widely chosen for safety barriers and guardrails due to their dependability and ability to provide protection.

- Q: Can steel sheets be used for manufacturing storage racks or shelves?

- Yes, steel sheets can be used for manufacturing storage racks or shelves. Steel is a strong and durable material, making it suitable for supporting heavy loads and providing long-lasting storage solutions. The versatility of steel sheets allows for customization in terms of size, shape, and design, enabling the creation of efficient and robust storage racks or shelves.

- Q: The difference between steel edge sealing strip and steel plate putty water stop belt

- The steel sealing strip is made of pure steel plate and can be divided into galvanized steel sheet, ordinary steel plate and stainless steel water stop belt.

- Q: Can steel sheets be used in the energy sector?

- Yes, steel sheets can be used in the energy sector. Steel is a versatile material that offers several advantages for various applications in the energy industry. It is commonly used in the construction of power plants, transmission towers, and infrastructure for renewable energy sources such as wind turbines and solar panels. In power plants, steel sheets are used in the fabrication of boilers, turbines, and other components. Steel's high strength and durability make it suitable for withstanding the high temperatures and pressures involved in power generation processes. It also offers resistance to corrosion and erosion, ensuring the longevity of critical equipment. Steel sheets are also utilized in the construction of transmission towers and substations. These structures support power transmission lines and facilitate the efficient flow of electricity across long distances. Steel's strong mechanical properties make it an ideal choice for these applications, as it can withstand the weight and stresses imposed by power transmission infrastructure. Furthermore, steel sheets are vital in the manufacturing of wind turbines and solar panels. In wind turbines, steel is used for the tower structure, which must be strong enough to support the weight of the rotor and withstand the loads from wind forces. Additionally, steel sheets are used in the construction of solar panel frames, providing rigidity and stability for the photovoltaic modules. Overall, steel sheets are widely used in the energy sector due to their strength, durability, and resistance to various environmental factors. The versatility of steel makes it a reliable choice for a range of applications, helping to support the generation and transmission of energy in both conventional and renewable energy sources.

- Q: Can the steel sheets be bent without cracking?

- Yes, steel sheets can be bent without cracking. The ability of steel sheets to be bent without cracking depends on a few factors such as the type and grade of steel, the thickness of the sheet, and the bending process used. Generally, steel sheets can be successfully bent without cracking as long as the bending radius and angle are within the recommended limits for that specific type and grade of steel. Additionally, preheating the steel sheet before bending can also help reduce the risk of cracking. It is important to follow proper bending techniques and use appropriate tools to ensure successful and crack-free bending of steel sheets.

- Q: Are steel sheets suitable for marine environments?

- Yes, steel sheets are suitable for marine environments. Steel is known for its high strength and durability, making it resistant to the harsh conditions found in marine environments, such as saltwater corrosion and extreme weather. Steel sheets are commonly used in shipbuilding, offshore structures, and other marine applications due to their ability to withstand the challenges posed by the sea. However, it is important to ensure proper maintenance and protective coatings to prevent corrosion over time.

Send your message to us

Zinc Coating Galvanized Sheets/ Coil/ GI Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords