Zinc Galvanized Corrugated Steel Iron Zinc Roof Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

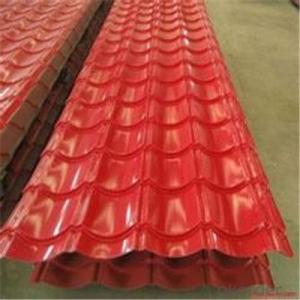

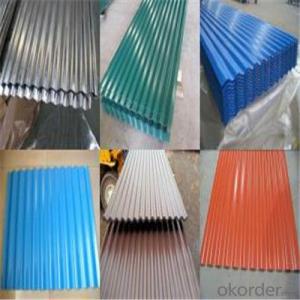

Description of Prepainted Corrugated Iron Sheet:

1. Hot-dipped galvanized

2. Color: All RAL color

3. Thickness: 0.23-1.0MM

4. Developed Width: 600mm to1200mm

Specifications of Prepainted Corrugated Iron Sheet:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Features of Prepainted Corrugated Iron Sheet:

(1) Novel and beautiful modeling , rich luster, strong adornment sex, flexible in combination, can express different architectural styles;

(2) Light weight (6 ~ 10 kg/m squared) high strength (yield strength 250 ~ 550 mpa) fine skin stiffness,fine seismic performance of waterproofing agent;

Images of Prepainted Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the different jointing methods for steel sheets?

- There are several different jointing methods that can be used for steel sheets, depending on the specific requirements and applications. Some of the most common jointing methods for steel sheets include: 1. Welding: Welding is one of the most widely used jointing methods for steel sheets. It involves melting the edges of the steel sheets and then joining them together by applying heat and pressure. Different welding techniques, such as arc welding, gas welding, or laser welding, can be used depending on the thickness and type of steel sheets. 2. Bolting: Bolting involves joining steel sheets together using bolts and nuts. This method is commonly used in applications where the joint needs to be easily disassembled or replaced. Bolting provides a strong and secure joint, and it can be used for both permanent and temporary connections. 3. Riveting: Riveting is a jointing method that involves using rivets to join steel sheets together. Rivets are cylindrical metal pins with a head on one end, and they are inserted through holes in the steel sheets. The rivet is then deformed to secure the joint. Riveting is often used in applications where high shear strength is required. 4. Adhesive bonding: Adhesive bonding involves using specialized adhesives to join steel sheets together. This method provides a strong and durable joint, and it is often used in applications where welding or other mechanical jointing methods are not suitable. Adhesive bonding also allows for a more uniform distribution of stress across the joint. 5. Mechanical fasteners: Mechanical fasteners, such as clips, clamps, or brackets, can also be used to join steel sheets together. These fasteners are designed to provide a secure and reliable connection without the need for welding or other permanent jointing methods. Mechanical fasteners are commonly used in applications where ease of assembly and disassembly is required. Overall, the choice of jointing method for steel sheets depends on factors such as the specific application, the desired strength and durability of the joint, and the ease of assembly and disassembly. It is important to carefully consider these factors and select the most appropriate jointing method to ensure a successful and reliable connection.

- Q: Can steel sheets be used for storage cabinets or lockers?

- Yes, steel sheets can be used for storage cabinets or lockers. Steel is a popular choice for these purposes due to its durability, strength, and resistance to damage. Steel sheets provide a sturdy and secure storage solution, making them ideal for cabinets and lockers. Additionally, steel is resistant to corrosion, which ensures that these storage units will last for a long time. The versatility of steel sheets allows for customization in terms of size, shape, and design, making it possible to create storage cabinets or lockers that meet specific requirements and fit seamlessly into any space.

- Q: What is the typical coefficient of thermal expansion of a steel sheet?

- The typical coefficient of thermal expansion of a steel sheet is around 10.8 x 10^-6 per degree Celsius.

- Q: Can steel sheets be used for railway applications?

- Yes, steel sheets can be used for railway applications. Steel sheets are commonly used in the construction of railway tracks, bridges, and other infrastructure due to their high strength, durability, and resistance to wear and tear. They provide a stable and reliable foundation for railway systems, ensuring safe and efficient transportation.

- Q: Are steel sheets resistant to rot or decay?

- Yes, steel sheets are highly resistant to rot or decay due to their inherent durability and resistance to moisture, fungi, and pests.

- Q: Can steel sheets be used for automotive suspension components?

- Yes, steel sheets can be used for automotive suspension components. Steel is a commonly used material in the automotive industry due to its strength and durability. It can provide the necessary support and stability required for suspension components to withstand various driving conditions and loads.

- Q: Are steel sheets resistant to UV rays?

- No, steel sheets are not inherently resistant to UV rays.

- Q: Steel plate for steel structure, what kind of steel plate is it?

- To make a steel plate, such a phrase, I think, is a little worse.This word is a relatively large range, according to that there is no special requirements, can use general steel: carbon steel structure can be, such as Q235, Q345, Q235 belong to ordinary carbon steel structure, Q345 is the last name 16Mn, belongs to low alloy series.But if it's special, it can be bridge, steel plate, Q235q, etc.. Q345q and so on.

- Q: How do steel sheets handle vibrations?

- Steel sheets have gained a reputation for their exceptional capacity to manage vibrations, primarily due to their high stiffness and strength. When exposed to vibrations, steel sheets have a tendency to absorb and diminish the energy of the vibration, thereby minimizing the transmission of these vibrations to other components of a structure or system. The inherent characteristics of steel, namely its high modulus of elasticity and limited damping capacity, play a significant role in its effectiveness in handling vibrations. The elevated modulus of elasticity allows steel sheets to resist deformation when subjected to external forces, thereby ensuring the maintenance of their structural integrity and stability during vibrations. Furthermore, the low damping capacity of steel allows it to efficiently dissipate the energy of the vibration, effectively preventing excessive oscillations or resonance. Steel sheets find widespread use in numerous applications that require resistance to vibrations, including industrial machinery, automotive components, and building structures. Their durability and dependable ability to handle vibrations make them a preferred choice in such scenarios. However, it should be noted that the specific performance of steel sheets in managing vibrations may vary depending on factors such as the thickness of the sheets, material composition, and design considerations.

- Q: How do steel sheets handle expansion and contraction?

- Due to its unique properties, steel sheets are capable of managing expansion and contraction in a predictable and controlled manner. Steel is renowned for its remarkable strength and durability, enabling it to endure the forces exerted during expansion and contraction without compromising its structural integrity. When steel sheets are exposed to high temperatures, such as those experienced during welding or in extreme environmental conditions, expansion occurs. This expansion is a result of the accelerated movement of steel molecules due to heat, leading to an increase in size. However, steel possesses a relatively low coefficient of thermal expansion, causing it to expand less compared to materials like concrete or wood. This property makes steel an advantageous choice for applications where dimensional stability is crucial. To effectively manage expansion, steel sheets are often designed with expansion joints or gaps that allow for movement. These joints can be found in structures such as bridges, buildings, or pipelines. They are strategically placed to accommodate the anticipated expansion and contraction of steel sheets without causing damage or deformation. Furthermore, the ability of steel to contract is equally significant. When exposed to lower temperatures, steel sheets shrink or contract. Although this contraction is typically less noticeable than expansion, it still needs to be taken into consideration in engineering designs. Fortunately, the contraction of steel is generally within acceptable limits and does not compromise the material's structural integrity. Overall, steel sheets are engineered to effectively handle expansion and contraction. The combination of a low coefficient of thermal expansion and the presence of expansion joints allows steel to accommodate temperature fluctuations without inducing significant stress or deformation. This makes steel a reliable and versatile material for numerous industries, including construction, manufacturing, and infrastructure.

Send your message to us

Zinc Galvanized Corrugated Steel Iron Zinc Roof Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords