Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Application of Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

Construction.

The manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

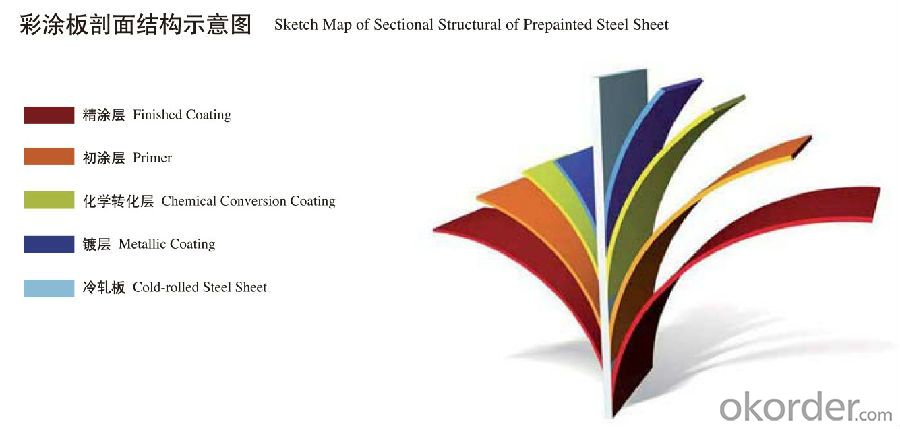

2.Features of Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

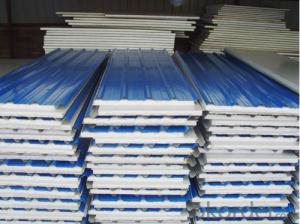

4. Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating image:

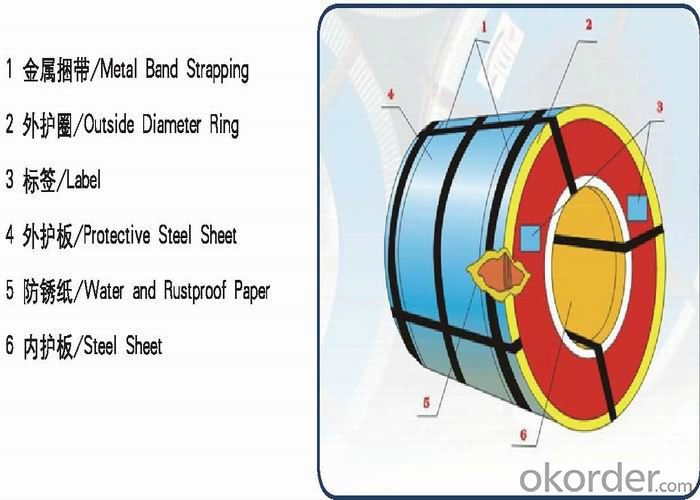

5.Packaging:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils coated for specific applications?

- Steel coils are coated for specific applications through a process called coil coating. This involves applying a protective layer of paint, polymer, or other coatings onto the steel coils using methods like roll coating or spray coating. The coating is carefully selected based on the desired properties such as corrosion resistance, durability, or aesthetic appeal required for the specific application.

- Q: What are the different methods of stretch leveling steel coils?

- There exists a variety of methods for stretch leveling steel coils, each possessing their own unique advantages and applications. 1. Roller Leveling: This method entails passing the steel coil through a sequence of rollers that apply pressure to stretch and flatten the material. It is a widely utilized technique for leveling steel coils and grants excellent control over the leveling process. Roller leveling proves suitable for thin and medium gauge steel coils. 2. Tension Leveling: In this approach, high tension forces are applied to the steel coil via a set of bridle rolls. The tension aids in elongating and flattening the material, resulting in a level and stress-free coil. Tension leveling proves particularly effective for thicker and harder steel coils. 3. Laser Leveling: Laser technology is harnessed in this method to assess and rectify any imperfections present in the steel coil. A laser scanner diligently scans the surface of the coil and detects variations, which are subsequently adjusted by a laser beam. Laser leveling provides exceptional precision and is suitable for leveling delicate and high-value steel coils. 4. Stretcher Leveling: This method involves exceeding the yield point of the steel coil, leading to permanent deformation and the elimination of residual stresses. Stretcher leveling is commonly employed for heavy gauge coils and is capable of achieving substantial improvements in flatness. 5. Tensionless Leveling: As the name implies, tensionless leveling is executed without the application of tension to the steel coil. Instead, hydraulic or pneumatic pressure is employed to stretch and flatten the material. This method is ideal for delicate or sensitive steel coils that may be susceptible to damage under high tension forces. Each method of stretch leveling steel coils possesses its own set of advantages, such as control, precision, or suitability for specific types of steel coils. The selection of the appropriate method relies on factors such as the thickness, hardness, and quality requirements of the steel coil, as well as the desired flatness and surface finish.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- 316L steel is the most basic metal used in body jewelry. It is the basic requirement of metal to be used in initial piercings and for healing. There are better grades but usually they cost more as well. For most people this grade of steel works just fine. Titanium is usually preferred over steel because it contains no nickel and it weighs almost 50% less than steel. Titanium can come in plain polish which looks just like steel AND it can come in a variety of colors (but NOT red or black). Titanium is super for people with sensitive skin to steel. It does cost a little more but is well worth it.

- Q: What are the common coil handling equipment used in the industry?

- Some common coil handling equipment used in the industry include coil cradles, coil cars, coil reels, coil straighteners, coil feeders, and coil tippers. These equipment are used to efficiently and safely handle coils of various sizes and weights during manufacturing processes.

- Q: How are steel coils used in the production of containers?

- Steel coils are used in the production of containers as they are the primary material for manufacturing container bodies. These coils are shaped and welded into the desired container shape, providing strength and durability to the final product.

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- Means you will have a nice booty, but the true question is... What does Buns of Steel mean by several times and SOON? Good luck.

- Q: How is steel different than iron?How many different kinds of steel are there?What type is the strongest?Which type is the weakest?

- steel has carbon in it instead of just iron there are hundreds if not thousands of different kinds of steel for different applications strength depends on the definition. some have stronger tensile (pull) strength than others.

- Q: I'm searching for the elastic modulus of ASTM A653 galvanized steel sheet. Max points for first person with a response that includes web address of reliable reference - I just haven't found it yet. thanks!

- Aluminum is non ferrous so a magnet won't persist with it, and this is softer than steel. once you have desperate that, if it has previous paint on it, this is particularly helpful to apply a primer that corresponds to the paint you would be utilising the two vinyl or oil based, then paint. this is possibly no longer Galvanized, yet whilst this is, the unpainted floor with have a 2 colour steel Spackle look.

- Q: Question about steel type used in bridges.?

- Do you mean galvanized steel?

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they serve as the primary material for constructing the bridge's structural components, such as beams and girders. These coils are processed through various stages, including cutting, shaping, and welding, to create the necessary structural elements that provide strength and support to the bridge. The durability and load-bearing capacity of steel coils make them ideal for withstanding the heavy loads and stresses experienced by bridges, ensuring their stability and longevity.

Send your message to us

Roofing Sheet / Prepainted Galvanized Steel Coil with Zinc Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords