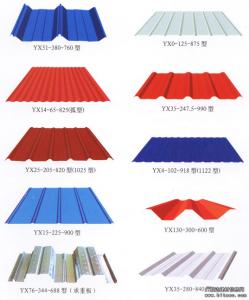

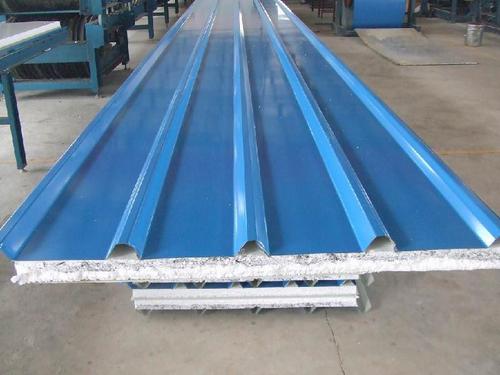

Color Coated Galvanized Steel Sheets for Corrugated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1) AVAILABLE DESIGNATION OF (Prepainted galvanized steel coils) printed PPGI coils

| Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

| EN 10327-2004 | (BASE PLATE) | |||

| (BASE PLATE) | ||||

| Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

| Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

| Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

| Steel | DX53D+Z/AZ | |||

| Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

| Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

2) OUR SPECIFICATION OF (Prepainted galvanized steel coils) printed PPGI coils

Available Size:

| Manufacturer | Thickness | Width | Length of plate | Inner diameter of coil |

| JIANGSU HUIYE STEEL SHEET CO.,LTD | 0.2-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass OF (Prepainted galvanized steel coils) printed PPGI coils:

| Base plate | Available Coated Mass(g/m^2) |

| Galvanized Steel | 80, 100, 120, 160, 180 |

| Galvalume Steel | 50, 70, 150 |

Available Painting OF (Prepainted galvanized steel coils) printed PPGI coils:

| Category of Painting | Item | Code | |

| Polyester | PE | ||

| High-durability polyester | HDP | ||

| Silicon modified polyesters | SMP | ||

| Polyvinylidene fluoride | PVDF | ||

| Easy-Cleaning | — | ||

| Painting Thickness | Top side: 20+5microns; | ||

| Bottom side: 5~7microns. | |||

| Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

| Painting structure | Top surface | Bottom surface | |

| Primer coating | No coating | 1/0 | |

| Primer coating | Primer coating | 1/1 | |

| Primer coating + Finish coating | No coating | 2/0 | |

| Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

| Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF OUR (Prepainted galvanized steel coils) printed PPGI coil

| Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

| Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

| Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

| Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

| Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils vary depending on the specific requirements and standards set by the industry. However, common tolerances for steel coils include thickness tolerances of +/- 0.001 to 0.005 inches, width tolerances of +/- 0.005 to 0.050 inches, and length tolerances of +/- 0.250 to 0.500 inches. These tolerances ensure that the steel coils meet the desired specifications and can be used effectively in various applications.

- Q: were iron age weapons made of steel?

- Even in very early iron, a small amount of steel was produced by carburization, where the iron picks up carbon by laying in hot coals before quenching. This produces a thin layer of steel on the surface of the iron. By about 300 BC Damascus steel was being produced by the crucible method on the Indian subcontinent, and the Romans used steel from Noricum. In the first century BC the Chinese were melting cast iron and wrought iron together to make steel.

- Q: What are the different types of steel coil storage racks?

- There are several different types of steel coil storage racks, including coil cradles, coil saddles, coil blocks, and coil storage bins. Each type is designed to safely and efficiently store steel coils based on their size, weight, and specific requirements.

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its dimensions and thickness. However, on average, a steel coil can weigh anywhere between 2 to 20 tons.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You could but you will have to run lower pressures and speed and thus lower power output. You should do some research the Me 262 the Nazi's built. I don;t know but I think they used steel. That's why the engine had to be serviced every few hours of flight.

- Q: How are steel coils used in the production of steel connectors?

- Steel coils are used in the production of steel connectors as they serve as the primary raw material. The coils are unrolled and then processed through various manufacturing techniques, such as cutting, stamping, and bending, to shape them into the desired connector forms. These connectors are crucial components used to join different steel structures together, ensuring strength, stability, and structural integrity in various applications like construction, automotive, and engineering industries.

- Q: How are steel coils used in the production of steel cables?

- Steel coils are used in the production of steel cables by being uncoiled and straightened, then fed into a machine that twists and braids them together to create the cable.

- Q: Steels like YHB-2, MVS-8, and SK-5. Also if you know anything about these steels that would be helpful.

- White steel is a common shorthand name for white paper steel (shirogami hagane) which can be any of several fairly simple high carbon, water hardening steel grades. The carbon content varies by grade, and runs from 0.8 to 1.4%. The range of carbon content within a grade is a tight 0.1%. For example, the carbon content of Shirogami Hagani No1A is specified to be between 1.3 and 1.4%. Each grade also contains 0.1-0.2% silicon and 0.2-0.3% manganese, and only trace amounts of the impurities sulfur and phosphorus. Blue paper steel (aogami hagane) is also offered in several grades, with carbon content ranging similarly to the white grades. However, blue steel contains the additional alloying elements chromium and tungsten, and one grade (aogami super) also contains molybdenum and vanadium. The blue steels can be quenched in water or oil, whereas most of the white grades need a faster quench and require water.

- Q: What are the challenges in welding steel coils?

- In order to guarantee successful and high-quality welds, it is necessary to address various challenges encountered when welding steel coils. One primary challenge involves achieving appropriate joint preparation. Steel coils often exhibit different surface conditions, such as rust, scale, or oil, which must be cleaned or eliminated before welding. This demands extensive cleaning and preparation to establish a clean and reliable welding surface. Another challenge lies in controlling the heat input. Due to the thin nature of steel coils, excessive heat can result in distortion, warping, or even burn-through. Welding operators must exercise careful control over the heat input to prevent such issues and uphold the integrity of the coils. Additionally, the presence of residual stresses poses a significant difficulty. Steel coils typically endure various stresses during the manufacturing, transportation, and handling processes, which can lead to distortion or cracking during welding. To mitigate these stresses and prevent potential defects, sufficient preheating and post-weld heat treatment may be necessary. Ensuring proper weld penetration is also of utmost importance. Steel coils often possess varying thicknesses, making it challenging to achieve consistent and adequate weld penetration throughout the joint. Welding operators must select appropriate welding parameters and techniques to guarantee complete fusion and a robust bond. Lastly, the size and weight of steel coils can create logistical challenges during welding. Specialized equipment and precise positioning are required to handle large and heavy coils, ensuring safe and efficient welding. Additionally, the length of the coils may necessitate multiple passes or continuous welding, demanding skilled operators and meticulous coordination. In conclusion, welding steel coils necessitates careful attention to joint preparation, heat control, stress relief, weld penetration, and logistical considerations. Overcoming these challenges guarantees the production of welded steel coils that are of high quality and durability.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

Send your message to us

Color Coated Galvanized Steel Sheets for Corrugated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords