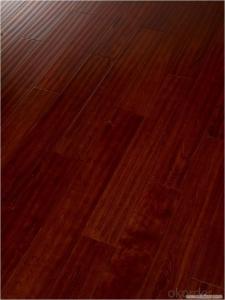

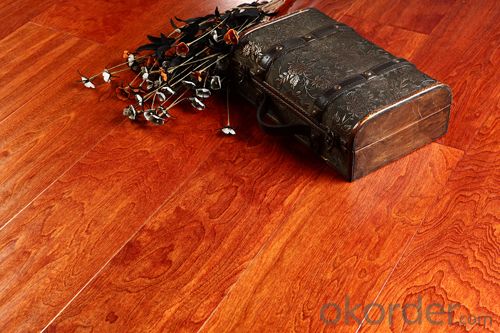

Yongsen Red Maple Antique Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Maple is divided into two kinds of hard and soft maple maple, is a temperate wood, wood is gray brown to gray and scarlet, the ring is not obvious, pipe hole and the small number of uniform distribution. Staggered maple wood, kidney structure is fine and uniform, soft and hard, fine pattern. Easy to process, the surface is not smooth, dry, easy to warp. Good performance, strong bonding strength. Mainly used for sheet metal plate.

2、Product Characteristic

1、 maple wood in the staggered, kidney structure is fine and uniform, lightweight and relatively hard, excellent pattern, color coordination, no scar knot, is a high-grade wood decoration. The world's best Canadian maple maple, also has the characteristics of warm in winter and cool in summer.

2、 Maple is a wonderful natural landscape, is the construction of decorative wood. It is easy to process, the surface is not smooth, dry, easy to warp. Good performance, strong bonding strength. Grip strength, strong, firm, durable, beautiful and high-grade.

White maple is a maple, now facing a lot of on floors and furniture, give people a fresh, simple feeling. More suitable for young people's aesthetic taste

3、Parameter

Material: Maple

Style: Modern

Standard: National Standards

Scope of application: Corridor

Pattern: Wood

Special purpose: wear resistant

Plate finish: good

Surface shape: hand grasp pattern

Residual depression: no

Formaldehyde release rate: E0

Resistance: good

Wear layer thickness: 3cm

Abrasion resistance: good

Fading (stage): 1

Floor thickness: 18mm

Color: Red

Specifications: 910*122*18

4、Reference pictures

- Q: What happens to the solid wood floor

- If the water is relatively large, alreadysoaked below, has obvious phenomenon of wet on the floor, I suggest you remove a part, buy some seasonings, absorb water on the ground, keep indoor ventilation, do not pay attention to the floor after exposure, water soaked or damp floor, if the sun will be the floor deformation, arch.

- Q: What is the difference between solid wood flooring and solid wood flooring

- Laminate flooring and solid wood flooring in raw materials, decoration effect, price, maintenance are very different.

- Q: i dont want to ruin it, i bought this stuff called scotts liquid gold that just smells delicious! it was like five dollars for this can of spray. is it safe to use? my flooring is called thomasville mahogany. i got it at home depot.

- Check with the manufacturer or where you bought them.

- Q: I have 2 small dogs and one big dog, which one would be the best? do they scratch easy? I defiantly don't want laminate, it looks too cheap.

- Hi, Hardwoods can be sanded if needed whereas engineered cannot. My dogs normal activity does not scratch my oak hardwood but when my son wrestles with the dog it does. We are going for the rustic look and do not worry about every little scratch as stuff happens. My neighbor has hardwood upstairs and laminate down and he says that the laminate does not get scratched by the dog. Every little mark bothers him so hardwood is not for him and he prefers tile or laminate. Hope this helps.

- Q: What is the difference between solid wood flooring and solid wood flooring? What are the advantages and disadvantages of each

- Advantages and disadvantages of solid wood flooring:(1) advantages:Humidity: wood floor by absorbing and releasing moisture, so the wooden floor can automatically adjust the indoor temperature and humidity, reduce rheumatic diseases, and because of its small coefficient of thermal conductivity, with Dongnuanxialiang effect (thermal insulation effect is very good). No matter any time of year, if a man sitting on the wooden floor, feel very comfortable, not cold, cold feeling, especially for families with children at home. Scientific research shows that the long-term residence of wooden huts, the average life expectancy can be extended for 10 years.Insulation material: solid wood flooring wood fiber structure is hard, careful, low thermal conductivity, sound barrier and heat effect is better than that of cement, steel and ceramic tile. Therefore, the wood floor has the functions of sound absorption, sound insulation, sound pressure reduction and short time function, and reduces the pollution effect of noise pollution.

- Q: Engineered wood flooring -- Durability and attractiveness in a 500+ patients/week in physicians' office?

- I don't see why not. Some of the laminates are extremely tough. You can almost put out a cigarette on some and they have great warranties.

- Q: What's the difference in quality!!!

- Solid wood flooring: Korea and Japan to the heating is very developed, the vast majority of the residents are solid wood flooring. I started on the floor and later through the study, found that absolutely ignorant of, wood flooring is the best choice for the following reasons: we all know that multi-layer solid wood flooring (parquet) in addition to advantages with wood floors but also has solid wood flooring lack such as: not easy to deformation, anti Alice good maintenance, not fragile.

- Q: engineered hardwood flooring = how good?

- i had to use because of concrete it marks and scratches easily go with hardwood if you can comparable price

- Q: Cork, 2-in-1 or something else? What are the advantages/disadvantages of each? Also, are these types of floors okay for installation in a kitchen?All installation is at or above grade. 30 year-old home with concrete slab.

- I would strongly suggest that you use the same manufacturer's underlayment. most of them come with attached moisture barrier (or thicker plastic). If not, make sure you install one first since you are installing on concrete slab. I have installed laminate wood on kitchen floors. but I personally prefer tiles in the kitchen, most durable, applicable, and appropriate kind of flooring for kitchen which is subject to extensive use and water contact. If you don't have kids in the house and not too many people, it's alright. I would recommend laminate wood though, very durable and easy to install. good luck!

- Q: Solid wood flooring environmental protection? How about the quality?

- Today, in order to survive the environment is no longer deteriorating, countries around the world attach great importance to the protection of forest resources, solid wood flooring and solid wood flooring can save rare timber resources. Experts remind friends wood flooring installation is simple, usually without a keel

Send your message to us

Yongsen Red Maple Antique Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords