Solid Merbau Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Quality Indoor Solid Merbau Flooring

1. Pre-finish: Treffert UV from German, natural oil or un-finished

2. Surface: normal; ha

Quality Indoor Solid Merbau Flooring

1. Pre-finish: Treffert UV from German, natural oil or un-finished

2. Surface: normal; hand scratched; archaized; brushed;

3. Joints: 4 sides T&G, with mirco bevel

Name: Solid Hardwood Flooring

Sizes (mm):

15/18 x 75/83/90/120/125/150/180/189 x RL

15/18 x 75/83/90/120/125/150/180/189 x 900 (FL)

Grade: A/AB/ABC/ABCD/BCD/CD

Technical Specification:

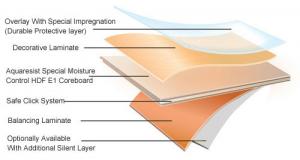

1. Varnishing: 7 layers coating of Treffert Aluminum Oxide finish, T&G, MR<12%.

2. Glue: Dynea Glue, exceed E1 standard.

3. Packing: Export Standard Carton & IPPC Pallets.

4. Pre-finish: Treffert UV from German, natural oil or un-finished

5. Surface: normal; hand scratched; archaized; brushed;

6. Gloss: semi-gloss: 35 +/- 5% High-light:75 +/- 5%

7. Joints: 4 sides T&G, with micro bevel

8. Packing: 8-20 Pcs in a carton, then packed in pallet, the pallet is shrink wrapped and strengthened, which means about 23 M3 per 20' container

9. Lead time: monthly production capacity is 80,000 M2.

- Q: which brand engineered wood floor is best?

- www.okorder / There's lots of good brands.

- Q: All my boards are in 3ft lengths. Do I need to cut them to various lengths before starting? What lengths should I cut them in? Does it look weird having a 3ft borad then a 8 inch board? Please help!

- If you don't want glue(Chemicals,formaldehyde)in the house you can use a rubber membrane on top of the concrete beneath the wood. It will give you a more solid floor than just floating it.Home depot has a product its a green roll membrane.

- Q: The year before the shop's solid wood floor, in the restaurant, the study of some of the surface of the floor, there is a small piece of transparent uplift, as if there is a bubble in the inside, with the hand can be pulled under the transparent coating, coating is very brittle. Is this coating a wax on the floor or a protective coating on the surface? After these coatings have gone off, there are a lot of marks on the floor. What should we do? Looking for a professional cleaning company to re waxing can solve it?

- If it is wax off, you can buy a new floor wax, according to the instructions to fight again. If it is the surface of the varnish off, to find a painter to deal with, the first wooden floor polished surface, and then paint, the paint on a few layers, the specific can consult the painter.

- Q: Home decoration, would like to use wood floors, I would like to ask you what is the difference between solid wood flooring and composite floor ah? Which brand is good

- Theory: solid wood flooring is wood drying, after the formation of the ground decoration materials. It has a pattern of natural, comfortable and safe use of. Solid wood flooring decorative style natural, suitable for modern people close to the needs of nature. From the point of view of environmental protection, solid wood flooring is better than the composite floor. Because wood floors Juegan good, step up feeling very thick, not like flooring as empty.

- Q: Solid wood floor price is probably now?

- The price of solid wood flooring is currently in the general quality of 240 yuan / square meter. High grade is more than 300 yuan. This is my understanding and division, in case of business discounts, may buy the original price of more than 200 yuan after the discount of about 160-180 yuan, which is good

- Q: Remodeling -- getting wood floors --- should I do solid or engineered wood flooring?

- solid wood all the way , it looks better and will add more value,and if you can afford it look into re claimed wood floors ...they are really nice

- Q: What should I look for in a quality engineered wood floor? Where is the best place to buy flooring if I'm installing it myself?

- Things to look for are the thickness of the wear layer, as well as the warranty. Engineered floors can be installed floating, or they can be glued, stapled, or nailed down. If they have the click-lock joint, they must be installed as a floating floor. If the joints are simple tongue and groove, and you install them as a floating floor, the joints must be glued. There are a lot of different places to get flooring. You can go to a home center, such as Lowe's or HD, or you can go to a flooring store. Do some shopping around, and pick up samples when you can so you can compare the floors. Hope this helps.

- Q: whats the different between this two type of wood for flooring??i don't really understand ... as i know hardwood was cut from timber and engineered wood was like few wood plank stack together...is that correct??which one better for flooring?? as in maintenance or pricewhich one worth??

- Engineered wood flooring is essentially plywood with a hardwood veneer for the top layer. It comes pre-finished, is stable, and easy to install. The thickness of the veneer layer can vary. Usually, there's enough so that the floor can be sanded and refinished....one time. Hardwood flooring is solid wood. It comes both pre-finished or unfinished. Being solid, it can be sanded and refinished many times. Installation is a bit more difficult than engineered wood. Some of the pieces develop a slight warp and it takes a lot of work to force them into a tight fit.

- Q: I'm looking at a hand-scraped birch engineered floor for my new house. My current house has solid Daru-Daru, an Indonesian hardwood near maple on the hardness scale. I've been very happy with my current floor. Will the engineered floor be comparable in durability?

- most new engineered flooring products are more durable, last longer, require less maintenance than natural products.

- Q: I read that some engeneered hardwood floor panels have high-density particle board layered in.There are also engeneered hardwood flooring that only has plywood layers and a natural-wood on top. Isn't particle-board worthless sawdust & glue that falls apart, looks shabby, puffs out.. over time? Doesn't it dissentigrate when wet? Is this really a good idea to put in flooring? Is High-density particle board worth anything as a component in engineered hardwood flooring? Is it better to avoid it like the plague?If I do use it, what sort of moisture-barrier should I put over the cement foundation? The house is about 15 years old, so, it's up to code & should have a moisture barrier under the cement foundation, according to the contractor I talked to, but, with PARTICLE-BOARD should I take extra precautions?How can you tell which engineered hardwood floors have HDPB, which have only plywood, and which are waterproof? I plan on getting it at Home Depot or Lowes. Thanks

- I agree with you that MDF or high-density particle board is not a good substrate. It swells up more than plywood when it gets wet or moist (just atmospheric moisture can be a problem; best to have air conditioning, but if that's impossible, use the plywood-based flooring). Glue is a component of plywood, too, but the plies are actual wood, not just chips of wood. Check out Bostik's products for sealers/adhesives to prepare a concrete slab for wood flooring. It's very important that you or your contractor use the recommended notched trowel to apply the sealer/adhesive.

1. Manufacturer Overview

| Location | Mudanjiang, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | 70.00% North America 10.00% Western Europe 10.00% Middle East 10.00% Domestic |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

Solid Merbau Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords