Teak Plywood

Teak Plywood Related Searches

Resin Plywood Mahogany Plywood Overlaid Plywood Marine Plywood Commercial Plywood Steel Laminated Plywood Plyron Plywood Blockboard Plywood Container Plywood Metal Laminated Plywood Colored Laminated Plywood Single Ply Plywood Beech Plywood Price Natron Plywood Foil Faced Plywood Fin Ply Plywood Phenolic Resin Ply Plywood 1.5 Inch Plywood Used Plywood For Sale Cost Of Plywood Impregnated Plywood Plywood For Sale Cheap 15Mm Plywood Roofing Plywood Sheets 5 X 7 Plywood Sign Board Plywood Fin Form Plywood White Plywood Sheets Wacky Board Plywood Plywood Per Square Foot PriceTeak Plywood Supplier & Manufacturer from China

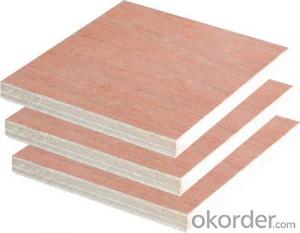

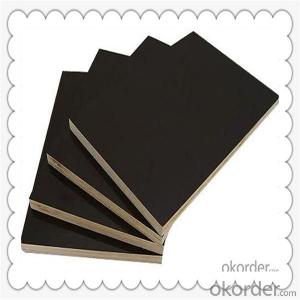

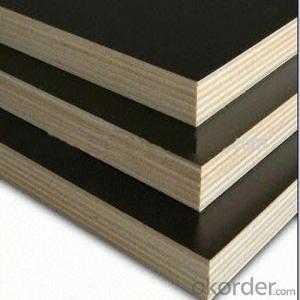

Teak Plywood is a high-quality wood product that boasts a combination of durability, strength, and aesthetic appeal. Made from layers of teak veneers bonded together with adhesives, this plywood is known for its resistance to decay, rot, and insect infestations. The unique properties of teak plywood make it suitable for a wide range of applications and usage scenarios. It is commonly utilized in the construction of marine vessels, outdoor furniture, and high-end interiors, where its natural resistance to harsh environmental conditions is particularly beneficial.Teak Plywood's versatility and resilience have made it a popular choice for various industries, including yacht building, luxury furniture manufacturing, and architectural design. Its natural beauty and rich coloration add a touch of elegance to any project, while its strength and durability ensure long-lasting performance. This makes teak plywood an ideal material for applications that require both aesthetic and functional qualities.

Okorder.com is a reputable wholesale supplier of Teak Plywood, offering a vast inventory of this sought-after product. With a commitment to providing high-quality materials at competitive prices, Okorder.com has established itself as a trusted source for teak plywood and other wood products. Their extensive inventory ensures that customers can find the exact specifications and quantities they need, making Okorder.com the go-to supplier for both large-scale projects and smaller, specialized applications.

Hot Products