Window Blinds Applied Prime Prepainted Galvanized Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:TDC51D+Z

Standard:ASTM, JIS, DIN, BS

Steel Grade:DC51d+Z

Certification:ISO

Surface Treatment:Coated

Technique:Hot DIP Galvanized

Application:Window Blinds Applied

Edge:Slit edge

Stock:Stock

Product Description:Prepainted Galvanized Steel

Brand Name:Cheeho & OEM

Base Metal:DC51d+Z

Available Dipped Layers:50-150G/M2

Inner Diameter:508mm

Temper Type:Ca

Available Coating Colors:off White & Sea Blue & Others

Approved Certificate:SGS & ISO & BV & TUV

Export Markets:Global

Additional Info.

Trademark:CheeHo & OEM

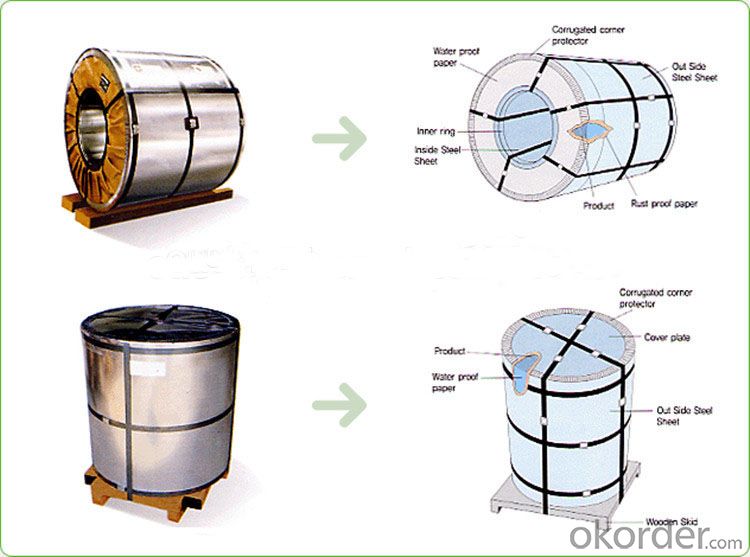

Packing:Standard Seaworthy Package with Wooden Pallet

Standard:SGS & ISO & BV & TUV Approved

Origin:Jiangyin, Jiangsu, China

HS Code:72107000

Production Capacity:150000mt/Year

Product Description

Brief Introduction

1. Prepainted Galvanized Steel is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metal for Prepainted Galvanized Steel is HDGI steel.

The finish coats of Prepainted Galvanized Steel can be classified into groups as follows: Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Galvanized Steel has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Galvanized Steel can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Specification

1. Thickness: 0.3-0.8mm

2. Width: 914-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Available Dipped Layer: 50-150G/M2

6. Surface Texture: Normal Coated

7. Type of coating structure: 2/1 Coat the top surface of the steel sheet twice, coat the bottom surface once, and bake the sheet twice.

8. Front Side Paint Thickness: 15-25μ M (bottom paint + top paint)

9. Back Side Paint Thickness: 5-10μ M

Common performance of front coating

1. Thickness: ≥ 20μ M

2. Pencil Hardness: 2H

3.60° Specular glossiness of coating: >60

4.180° Bend: ≤ 3T

5. Impact: ≥ 9J

6. Salt Fog Resistant: ≥ 500h

7. Color difference:<3Δ E

Packing

We use Seaworthy Package to make sure Prepainted Galvanized Steel is well-protected during the long ocean voyage.

Application

1. Construction: (Outside) workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door

(Inside) door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter

2. Electrical appliance: Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

3. Furniture: Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf

4. Carrying trade: Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

5. Others: Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

Superiority

1. We had already passed the authentification by the ISO9001 and established a completed set of quality assurance system.

2. Under such a complete set of quality assurance systems, there is a complete set of regulations for ordering, order handling, quality design, purchasing raw materials, working out production plan, production, test and inspection, packaging, storage, delivering, etc.

3. The PC-based production and marketing system not only improves the working efficiency but also assures the quality of product.

4. Our Prepainted Galvanized Steel lines are equipped with a large amount of online test instruments so that they can ensure and improve the quality of product.

5. We also have a complete set of equipment and techniques for testing and controlling the performance of the Prepainted Galvanized Steel products, which ensures our product quality to take a leading position among the fellow products at home and reach the international standard.

Mechanical properties of base metal

| Grade | Tensile Test | ||

| Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

| DC01 | 280-325 | 320-500 | 22 |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the different methods of perforating steel coils?

- There are several methods of perforating steel coils, including rotary punch, laser cutting, and stamping. Each method offers its own advantages and is chosen based on factors such as the desired hole size, material thickness, and production volume. Rotary punch involves using a rotating tool to create holes in the steel coil, while laser cutting uses a high-powered laser beam. Stamping, on the other hand, involves using a die and press to create holes by applying pressure to the steel coil.

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, the main factors to consider include the supplier's reputation and reliability, the quality of their products, their pricing and payment terms, their delivery options and lead times, their customer service and support, as well as their ability to meet your specific requirements and specifications.

- Q: Can steel coils be coated with epoxy?

- Yes, steel coils can be coated with epoxy. Epoxy coating provides a protective layer that enhances the durability and corrosion resistance of steel coils.

- Q: What are the different methods of levelling steel coils?

- There are several methods used for leveling steel coils, depending on the specific requirements and applications. Some of the common methods include: 1. Roller Leveling: This method involves passing the steel coil through a series of rollers that exert pressure on the material, effectively reducing any residual stresses and removing any waviness or curvature. Roller leveling is commonly used for thinner gauge coils where a high degree of flatness is desired. 2. Stretch Leveling: This method involves stretching the steel coil beyond its yield point to eliminate any shape defects. The coil is subjected to tension in a stretcher leveler machine, which elongates the material and removes the inherent stresses. Stretch leveling is often used for thicker gauge coils where a higher degree of flatness is required. 3. Temper Milling: This method involves passing the steel coil through a temper mill, which is a cold reduction mill equipped with work rolls on top and bottom. The temper mill imparts tension on the coil, flattening it and improving its shape and surface quality. This method is typically used for higher strength steel grades. 4. Corrective Leveling: This method is employed when the steel coil has significant shape defects, such as wavy edges or center buckles. Corrective leveling involves selectively removing material from specific areas of the coil to achieve a flat and uniform surface. This process is often done using laser or plasma cutting machines. 5. Tension Leveling: This method is similar to stretch leveling, but it involves applying tension to the coil without exceeding its yield point. Tension leveling utilizes a series of bridle rolls to stretch the material, thereby removing any internal stresses and leveling the coil. This method is commonly used for higher strength and thinner gauge coils. These methods can be used individually or in combination depending on the specific requirements of the steel coil and the desired end product. Each method has its advantages and limitations, and the choice of leveling method will depend on factors such as the coil thickness, material properties, and desired flatness.

- Q: How are steel coils used in the production of roofing sheets?

- Steel coils are used in the production of roofing sheets by being processed through a series of steps, including rolling, cutting, and shaping. The steel coils are uncoiled and then passed through a roller system to flatten and shape them into thin sheets. These sheets are then cut to the desired length and width. Finally, they undergo various treatments, such as galvanization or coating, to enhance their durability and resistance to corrosion. Overall, steel coils serve as the primary raw material for manufacturing high-quality roofing sheets.

- Q: How are steel coils used in the production of steel framing systems?

- Steel coils are used in the production of steel framing systems as they are unrolled and fed into a machine that shapes and cuts the steel into the desired lengths and profiles. These coils provide a continuous supply of high-quality steel, allowing for efficient and precise manufacturing of steel framing components, which are then assembled to create sturdy and durable steel structures.

- Q: I also heard Stainless holds up better againts rust, blue steel needs more care.

- They have different properties. Bluing on steel is a surface treatment that helps inhibit rust, but doesn't prevent it. It will wear off with use over time, but can be redone. Stainless steel refers to a particular type of steel alloy, usually incorporating nickel and chromium, that is highly resistant to rust on its own, so doesn't need a surface treatment. Because the steel itself is what is rust resistant, that property can't wear off. All other things held equal, the carbon steel that bluing is typically applied to tends to be slightly more rigid and brittle than stainless steel. It may hold an edge better than stainless. In most applications, those differences are small enough not to matter for practical purposes. For example, both knives and guns are made with blued steel and stainless steel. Which a person gets is usually a matter of preference (unless you're, say, a professional restaurant chef whose knives have to hold a fine edge through constant hard use).

- Q: I have samurai sword that is a replica of the kill bill sword. It says on the blade stainless steel, what can i use to shine and protect blade. It had and still does a wax.like coating on the blade sine i received it. Thx for ur help

- Normally okorder

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- I know nothing about Superman nor have I watched the other films or read the comics. Man Of Steel was a CGI-fest, maybe a little bit too much, though it is Zack Synder's style. I actually fell asleep for most of the movie, seeing only the first 30 minutes and last 45 minutes? So that might be a good indication or it could just be me. There were loads of action scenes but overall, the movie wasn't that impressionable to me. The storyline was quite standard and had nothing outstanding, not even humour. Lois Lane and Superman barely had much screen time together to establish any chemistry. The other characters were pretty flat as well. I did like the dark psychological themes of Superman's struggles and coming to terms with his abilities though.

- Q: I would like to build steel galvanization plant.

- That's depending on what type of metal you want to cover the steel parts in the galvanization process. The galvanization in words refers only to that kind of process which is using electric deposition of a metal through a bath of a electrolyte from a plate containing pure metal needing to be deposed on steel tide at the anode electrode or + polarity and at the other side (other electrode, cathode or - polarity). There needs to be a certain recipe of mixed salts for creating very tight and uniform growth crystals, for not being corroded or leafed away with time. There are certain salts which provide this king of growing in the same time with the polished look of the piece galvanized. This salts can be dissolved in water, for creating the electrolyte or being melt (which is not so safe technique) and used and kept like that. The dipping is no so used any more and it can not be called galvanization. More recent techniques use hot plasma blowers, meaning a torch with plasma and a wire of the specific metal to be deposited being melt in the plasma and blown to the surface of the steel part. Anything you'll do you have to deal with the local Environmental Agencies and with the tap water supply/ sewerage administrator, because you;ll have to make a contract with them for you to show that you retain the hard metals from the water dropped to sewerage, if any. Dfriend:)

Send your message to us

Window Blinds Applied Prime Prepainted Galvanized Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords