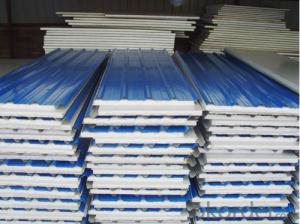

Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet/Pre-painted Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted steel coil

Specifications

1.Standard: ASTM,GB,JIS

2.Grade : DX51D+Z

3.Thickness: 0.18-1.5mm

4.Width:914-1250mm

5.Top paint:20mil,Black paint:7mil

6. Technical/Surface treatment: color coated/galvanized/galvalume

7..Useage: widely used in construction,home,appliance,decoration,wear resistant steel,etc.

Advantages:

1. more than 10 years experiences in steel b2usiness

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

Company :

CNBM is the specialized manufacturer of the prepainted steel coil ,

including the PPGI and PPGL . And our products have exported to Korea , Southeast Asia ,

Russia , Middle East ,South America ,South Africa ,Northern Europe and do on .

Product :

Commodity : | Prepainted steel coil /PPGI /PPGL |

Materials Grade: | SGCC ,CGCC ,DX51D+Z ,SGLCC |

Thickness : | 0.17-1.2mm |

Width : | 914mm,1219mm,1000mm,1220mm,1250mm ( can cut to strip above 30mm width ) |

Zinc coating : | 60-275g/sqm |

Surface Structure: | Galvanized Or Aluzinc |

Color : | RAL No. or Sample color |

Painting : | Top : 5micron primer +15-20microns polyester |

Coil Weight : | 2-6mts |

Payment term : | TT ,L/C AT SIGHT , USANCE L/C ,D/P |

Shipment : | 20 feet container or bulk ship |

Remark : | We accept the third-party inspection ,such as SGS , |

- Q: How does coil slitting work?

- Coil slitting is a process used to cut large coils of material, such as metal or plastic, into narrower strips. It involves feeding the coil through a set of rotating circular blades that make longitudinal cuts along the length of the coil. The blades are set at predetermined widths to achieve the desired strip thickness. The process is usually automated and ensures efficient and precise cutting, resulting in multiple narrower coils that can be used for various industrial applications.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- I agree with everything that Lester said. Another thought is to consider starting on a lap steel guitar rather than a pedal steel - its related, a little easier to learn on, and less expensive. Once you get proficient on the lap steel, you can move up to the pedal steel. Good luck!

- Q: I wanna strip down my bike and take off all the paint... im thinking of leaving it just the steal color... Do i need to put anythinng on the steel to coat it or can i just leave it like that... Will it rust or anything?

- There is another thing you can do to inhibit corrosion on bare metal surfaces. Use a good quality automotive wax. Apply it with diligence, and keep the bike in the garage when you're not using it so it stays dry. Touch up the wax job every now and then to maintain the protective finnish.

- Q: How do steel coils contribute to the automotive industry?

- Steel coils play a significant role in the automotive industry by contributing to the manufacturing of various components and structures in vehicles. These coils are made from high-quality steel and undergo a series of processes, including hot rolling, cold rolling, and annealing, to achieve the desired properties. One of the primary uses of steel coils in the automotive industry is in the production of body panels and frames. The high strength and durability of steel make it an ideal material for these applications, providing structural integrity and protection to the vehicle. Steel coils are transformed into sheets through a stamping process, allowing manufacturers to create complex shapes and designs for different vehicle models. Moreover, steel coils are also used in the production of suspension systems, including springs and shock absorbers. The elasticity and resilience of steel allow these components to withstand the constant impact and weight of the vehicle, ensuring optimal performance and comfort for the driver and passengers. Additionally, steel coils are utilized in the manufacturing of engine components, such as crankshafts, camshafts, and cylinder heads. These components require the strength and thermal resistance that steel provides, ensuring the efficient operation and longevity of the engine. Furthermore, steel coils are crucial in the production of exhaust systems, which play a vital role in reducing emissions and noise levels. Steel's resistance to heat and corrosion make it an ideal material for exhaust pipes, mufflers, and catalytic converters, ensuring their durability and functionality. Overall, steel coils are indispensable in the automotive industry as they contribute to the production of various components and structures that are essential for the performance, safety, and longevity of vehicles. The high strength, durability, and versatility of steel make it a preferred material choice, enabling manufacturers to create reliable and efficient automobiles.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- another name is Grey iron, come from groups of ferrous alloys

- Q: What are the challenges in coil blanking for complex shapes?

- Coil blanking for complex shapes presents several challenges that need to be addressed in order to achieve accurate and efficient results. One significant challenge lies in the precise positioning and alignment of the coil material. Complex shapes often require intricate cutting patterns, and any misalignment or deviation can lead to inaccurate cuts and wasted material. Another challenge is the selection and optimization of the blanking tooling. Complex shapes often require specialized dies and punches, which need to be carefully designed and manufactured to ensure accuracy and consistency. This not only involves the selection of appropriate tooling materials but also the consideration of factors such as cutting forces, wear resistance, and tool life. The complexity of the shapes also poses challenges in terms of material deformation and springback. During the blanking process, the material undergoes various deformations and stresses, which can cause distortions and dimensional variations in the final product. Achieving the desired shape while minimizing these deformations requires a thorough understanding of material properties and advanced techniques such as compensation and adjustment in the die design. Furthermore, the high-speed nature of coil blanking for complex shapes can lead to increased vibration and noise levels. The dynamic forces involved in cutting intricate shapes can result in tool chatter and excessive noise, which not only affects the quality of the cut but also the overall operational efficiency. Implementing effective damping and vibration control measures, such as tool coatings and optimized cutting parameters, is crucial to mitigate these challenges. Lastly, the complexity of the shapes can also impact the overall production efficiency. Complex shapes often require longer tool setup times and more frequent tool changes, which can lead to increased downtime and reduced productivity. Additionally, the intricate nature of the cuts may require multiple passes or additional machining operations, further adding to the production time and complexity. To overcome these challenges, manufacturers need to invest in advanced technologies, such as computer-aided design and simulation software, to optimize the blanking process. Additionally, continuous research and development efforts focused on improving tooling materials, cutting techniques, and process control can help address the challenges associated with coil blanking for complex shapes.

- Q: I know the law regarding selling steel core ammo, but is it possible to buy a steel core bullet and load it yourself?

- Please okorder / You're likely to find steel core ammunition from any of those manufacturers, and many more. Have fun... but steel core ammo is no more effective than lead ammunition, unless you're planning a crime spree and want to attempt to punch through a ballistic vest, and even that's not guaranteed.

- Q: I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- Welcome to the life of stainless steel cookware. Make sure you have plenty of steel wool handy. It took my wife and I some getting used to, but we now love our set.

- Q: What are the common surface treatments for galvanized steel coils?

- Some common surface treatments for galvanized steel coils include passivation, chromate conversion coating, and painting. Passivation helps to enhance the corrosion resistance of the galvanized coating, while chromate conversion coating provides additional protection and improves adhesion for subsequent paint coatings. Painting can be done to enhance aesthetics or to provide additional corrosion protection, depending on the specific requirements of the application.

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in the manufacturing of agricultural equipment. Steel coils are used to fabricate various components such as frames, chassis, and structural parts that require strength and durability in agricultural machinery.

Send your message to us

Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet/Pre-painted Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords