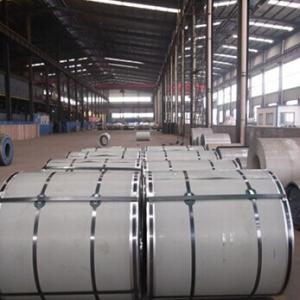

High Quality Cold Rolled Steel for Buildings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Certification:ISO

Technique:Cold Rolled

Standard:GB

Application:Container Plate

Edge:Slit edge

Stock:Stock

Steel Grade:SPCC DC05

Export Markets:Global

Additional Info.

Packing:According to The Customer Request

Standard:SGS. ISO

HS Code:72099000

Production Capacity:250000ton/Year

Product Details

Basic Info.

Technique:Cold Rolled annealing skim

Steel Grade:spcc dc05

Technique:Cold Rolled

Export Markets:Global

Approved Certificate:SGS & ISO

Surface Treatment:Oiled

Additional Info.

Trademark:xianghe

Packing:Standard Seaworthy Packing, Bundle or Pallet

Origin: Zibo,Shandong,China

HS Code:72099000

Product Description.

1.Thickness: 0.2mm-1.3mm

2. Width:660mm~1000mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed

6. Surface Quality: FB&FC

7. Surface Status: SB & SD

| Skim the steel plate | Cold rolled steel sheet | ||

| width | Thickness(mm) | width | Thickness(mm) |

| 660mm~1000mm | 0.2mm-1.3mm | 660mm~1000mm | 0.2mm-1.3mm |

Cold Rolled Steel is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel is then passed through rollers to reduce its thickness.

- Q: Just wondering how good are forge steel screw drivers, tool boxes(organisers) and pliers are, as screw fix are having a january sale, and looking to add to my tool collection. Thanks in advance

- Forge Steel

- Q: I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- No, you will damage the guitar,it was not create to stand the force on the neck that steel strings will put on it.

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing typically include factors such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards set by organizations like ASTM or ISO.

- Q: What are the challenges in coil blanking?

- In order to achieve efficient and accurate production, coil blanking, a process used to cut flat metal sheets from coiled stock, must tackle several challenges. Some of the key challenges include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality, which can impact the cutting process and result in inconsistent blanks. To ensure consistent quality and dimensional accuracy, it is crucial to carefully select and control the material. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature), which can cause alignment issues during cutting. Minimizing these imperfections requires the use of specialized equipment and techniques, such as straighteners and leveling systems. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Employing proper edge conditioning techniques, like deburring or edge trimming, is necessary to ensure clean and straight edges. 4. Slitting and shearing forces: The forces exerted during coil blanking can induce stresses and strains in the material, potentially leading to deformation or springback. To minimize these effects and maintain dimensional accuracy, careful consideration of slitting and shearing forces, along with proper tooling design and machine settings, is necessary. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and reducing material waste is crucial to optimize production efficiency and minimize costs. Efficient nesting algorithms and real-time monitoring systems can help achieve this. 6. Automation and productivity: Due to market demands, coil blanking often requires high-speed and high-volume production. Enhancing productivity can be achieved through the implementation of automation systems, such as robotic material handling and advanced control systems. However, integrating and synchronizing these components with the cutting process requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking necessitates proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- Weldable steel is a generic term for steel with low carbon content which makes it easy to weld, form, and machine. If you're looking for a knife blade material, you need either a stainless steel or a high carbon steel which is not at all weldable. The more carbon in steel, the better it responds to heat treatment like hardening, tempering, etc. Plus, the high carbon steel will hold an edge better. Hope this helped.

- Q: What are the common coil finishes available for steel coils?

- Steel coils can be finished in various ways to serve different purposes and achieve different aesthetic appearances. Some popular coil finishes include: 1. Hot-dip galvanized: By immersing the steel coil in molten zinc, a protective layer is formed on its surface. This finish is ideal for outdoor applications like roofing, fencing, and automotive parts due to its excellent corrosion resistance. 2. Galvannealed: Achieved by annealing the hot-dip galvanized coil, this finish gives a matte gray appearance. Galvannealed coils have enhanced paint adhesion, making them suitable for subsequent painting or powder coating in applications like appliances and furniture. 3. Electro-galvanized: A thin layer of zinc is electroplated onto the surface of the steel coil in this process. Electro-galvanized finishes offer good corrosion resistance and are commonly used indoors, such as in electrical enclosures, HVAC systems, and automotive components. 4. Pre-painted or coated: These finishes involve applying a layer of paint or a coating system to the steel coil, improving its appearance and providing extra protection. Pre-painted coils are extensively used in construction, appliances, and automotive industries due to their aesthetic appeal and corrosion resistance. 5. Bare or mill finish: This refers to the untreated, raw steel coil without any additional coatings or finishes. Bare steel coils are commonly used in applications where corrosion resistance is not the main concern, such as structural components, pipes, and tubes. These are just a few examples of the many coil finishes available for steel coils, each offering unique properties and advantages depending on the intended use. Carefully considering the specific requirements of the application is important when choosing the most suitable coil finish.

- Q: What is the average turnaround time for processing steel coils?

- The average turnaround time for processing steel coils can vary depending on various factors such as the complexity of the process, size of the coils, and the efficiency of the manufacturing facility. However, in general, the average turnaround time for processing steel coils ranges from a few days to a few weeks.

- Q: How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q: What are common uses for steel coils?

- Common uses for steel coils include manufacturing automobiles, construction materials, appliances, pipes, and various industrial applications such as manufacturing machinery and equipment.

- Q: How are steel coils protected from humidity?

- Steel coils are protected from humidity by applying a layer of corrosion-resistant coating, such as zinc or aluminum, to the surface of the coils. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and reducing the risk of corrosion. Additionally, the coils are often stored in a controlled environment with low humidity levels to further minimize the impact of moisture.

Send your message to us

High Quality Cold Rolled Steel for Buildings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords