Wholesale Anodized Aluminum Extrusion Profiles in Color RAL from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Anodized Aluminum Perfile in Color RAL from China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Anodized Aluminum Perfile in Color RAL from China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Anodized Aluminum Perfile in Color RAL from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

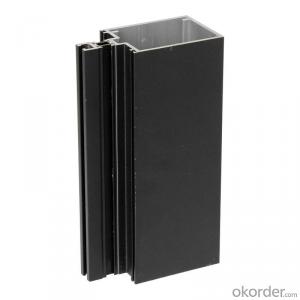

5. Image of Anodized Aluminum Perfile in Color RAL from China

6. Package and shipping of

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles generally exhibit good heat resistance. Aluminum has a high thermal conductivity, allowing it to efficiently dissipate heat. Additionally, aluminum profiles can withstand high temperatures without deforming or losing structural integrity. However, extreme temperatures, especially above 600°C, can cause aluminum to gradually lose strength. Therefore, it is important to consider the specific application and temperature requirements when evaluating the heat resistance of aluminum profiles.

- Q: How do aluminum profiles perform in terms of weather resistance?

- Aluminum profiles exhibit remarkable weather resistance due to the unique qualities of aluminum itself, such as its resistance to corrosion and ability to endure harsh environmental conditions. To enhance their weather resistance, aluminum profiles are typically coated or anodized, providing long-lasting durability and protection against different weather elements. The corrosion resistance of aluminum is especially advantageous for outdoor applications. When exposed to oxygen, aluminum naturally forms an oxide layer, serving as a protective barrier against rust and deterioration. Consequently, aluminum profiles are highly resistant to moisture, rain, and humidity, making them suitable for use in coastal areas or regions with high levels of precipitation. Moreover, aluminum profiles also possess resistance against UV radiation. The application of surface treatments, such as powder coating or anodizing, adds an extra layer of defense against the sun's harsh rays. Consequently, aluminum profiles do not fade, chip, or crack when exposed to prolonged sunlight, ensuring their original appearance and structural integrity are preserved over time. Concerning extreme weather conditions, aluminum profiles are specifically designed to withstand high winds, extreme temperatures, and even severe storms. They possess excellent mechanical properties, including high strength and stiffness, enabling them to bear heavy loads and resist deformation. As a result, aluminum profiles are ideal for applications in construction, architecture, and outdoor infrastructure projects where weather resistance is of utmost importance. In conclusion, aluminum profiles exhibit exceptional weather resistance. Their inherent corrosion resistance, combined with the availability of various surface treatments, ensures their ability to endure a wide range of weather conditions while maintaining their structural integrity and aesthetic appeal.

- Q: How do you ensure proper alignment and accuracy when using aluminum profiles?

- To achieve accurate alignment and precision when utilizing aluminum profiles, there are several crucial measures that can be implemented: 1. Opt for top-notch aluminum profiles that are manufactured with utmost precision and possess consistent dimensions. This will minimize profile variations and facilitate the attainment of accurate alignments. 2. Before commencing any assembly, meticulously cleanse the profile surfaces and any connecting elements like brackets or connectors. This will eliminate any dirt, dust, or debris that may hinder the alignment process. 3. Employ precise measuring tools such as rulers, calipers, or laser levels to meticulously measure and mark the intended positions for the profiles. This will guarantee correct alignment from the outset. 4. When connecting or joining multiple profiles, utilize alignment aids such as alignment pins or clamps. These aids will assist in holding the profiles in place while adjustments are carried out to achieve proper alignment. 5. Dedicate ample time to meticulously inspect and adjust the alignment at various points along the profile length. This will aid in identifying any inconsistencies or misalignments that may have occurred during the assembly process. 6. Prior to finalizing any connections or securing the profiles in place, thoroughly recheck all measurements and alignments. This will help prevent potential issues or errors that may arise later on. 7. If necessary, utilize shims or spacers to fine-tune the alignment. These minor adjustments can compensate for slight variations or inconsistencies in the profiles or installation surface. 8. Lastly, ensure that all connections and fasteners are securely tightened, without excessive force. Over-tightening can lead to misalignments or distortions, while loose connections can compromise the integrity and accuracy of the assembly. By diligently following these steps and paying meticulous attention to detail, it is possible to achieve proper alignment and precision when utilizing aluminum profiles. This will result in a robust and accurate structure that meets the desired specifications.

- Q: This question asks for an explanation of the various methods employed in the manufacturing of aluminum profiles.

- <p>Aluminum profiles are produced using several manufacturing processes, each suited to different applications and profile shapes. The primary methods include: Casting, where molten aluminum is poured into molds to form profiles; Extrusion, the most common process, where aluminum is pushed through a die to create long, continuous shapes; Rolling, used for creating flat or curved sheets and plates; Forging, which involves shaping aluminum by applying compressive forces; and Machining, where aluminum profiles are cut and shaped using tools. Each process has its advantages and is chosen based on the desired profile's complexity, strength, and cost-effectiveness.</p>

- Q: The aluminum panel is the cart, ordinary nylon plate, the wheel is not conductive wheel, why use aluminum surface will be static, but not in the nylon plate, not easy to produce electrostatic in high resistance material?

- To protect its surface finish!These thin film aluminum surface coverage of excellent conductivity and it is insulated! Then in normal environment and similar objects formed aluminum will static capacitance effect! This principle is that it can form the electrostatic charge accumulation!

- Q: Can aluminum profiles be used in the construction of exhibition booths?

- Yes, aluminum profiles can be used in the construction of exhibition booths. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular exhibition booths. These profiles can be easily assembled and disassembled, allowing for easy transportation and reconfiguration of the booth layout. Additionally, aluminum profiles offer a sleek and modern aesthetic, providing a professional and visually appealing display for exhibitors. They can be used to create frames, partitions, shelving, signage, and various other components required for exhibition booths. Overall, aluminum profiles offer a cost-effective and efficient solution for constructing exhibition booths.

- Q: Can aluminum profiles be used in the production of industrial machinery?

- Yes, aluminum profiles can be used in the production of industrial machinery. Aluminum is a lightweight yet strong material that offers excellent strength-to-weight ratio, corrosion resistance, and machinability. It can be easily formed into various shapes and profiles, making it suitable for constructing frames, enclosures, support structures, and other components in industrial machinery. Additionally, aluminum profiles are highly customizable and can be engineered to meet specific design and functional requirements, making them a preferred choice in many industrial applications.

- Q: Can aluminum profiles be used in the production of agricultural machinery?

- Yes, aluminum profiles can be used in the production of agricultural machinery. Aluminum is a lightweight and durable material that can withstand harsh environmental conditions, making it suitable for various components and structures in agricultural machinery. Additionally, aluminum profiles offer flexibility in design and can be easily customized to meet specific requirements, enhancing the efficiency and performance of agricultural equipment.

- Q: Can aluminum profiles be used for display systems?

- Yes, aluminum profiles can be used for display systems. They are lightweight, durable, and versatile, making them ideal for creating custom display structures such as exhibition booths, retail displays, and signage. Aluminum profiles can be easily assembled, disassembled, and reconfigured, allowing for flexibility and easy transportation. Additionally, they can be powder-coated or anodized in various colors to match the desired aesthetic. Overall, aluminum profiles offer a reliable and cost-effective solution for display system applications.

- Q: Can aluminum profiles be used in roofing systems?

- Yes, aluminum profiles can be used in roofing systems. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an ideal choice for roofing applications. Aluminum profiles can be used to create various roofing components, such as gutters, downspouts, and flashing, which help to channel water away from the roof and prevent leaks. Additionally, aluminum profiles can be easily fabricated and customized to fit the specific requirements of a roofing system. Overall, aluminum profiles offer numerous advantages for roofing systems, including strength, durability, and resistance to weathering, making them a popular choice for both residential and commercial roofing projects.

Send your message to us

Wholesale Anodized Aluminum Extrusion Profiles in Color RAL from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords