20x40mm Aluminum Profiles for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Extrusion for Electric Power Engineering Sector Description

Aluminum Extrusion for Electric Power Engineering Sector is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminum Extrusion for Electric Power Engineering Sector

Aluminum Extrusion for Electric Power Engineering Sector | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminum Extrusion for Electric Power Engineering Sector

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminum Extrusion for Electric Power Engineering Sector

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminum Extrusion for Electric Power Engineering Sector

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

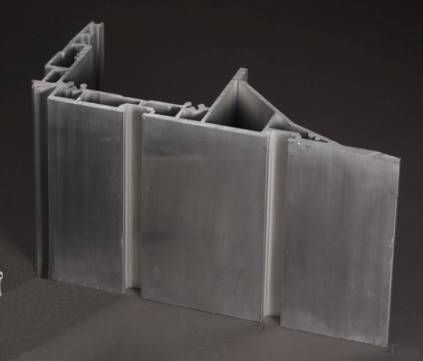

6. Image of Aluminum Extrusion for Electric Power Engineering Sector

7. Package and shipping of Aluminum Extrusion for Electric Power Engineering Sector

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- The price of the equipment is not primary, mainly because of the technical requirements of oxidation. "This is not as simple as you think."

- Q: How to deal with the mechanical surface of aluminum profile?

- Mechanical texture removal also has mechanical methods, chemical methods can not remove deeper texture, if sand blasting effect is acceptable, you try sand blasting or shot peening

- Q: Can aluminum profiles be used for modular exhibition booths?

- Indeed, modular exhibition booths can utilize aluminum profiles. Being light in weight, durable, and simple to assemble, aluminum profiles prove to be an excellent selection for crafting such booths. Customization and reconfiguration of these profiles to meet specific design needs is effortless. Moreover, these profiles provide a polished and professional look and can be employed in constructing walls, frames, panels, and display shelves within the booth. Furthermore, aluminum profiles are easily transportable and storable, rendering them a pragmatic choice for exhibition booths that require frequent setup and dismantling.

- Q: in addition to the groove width is not the same as other well differentiated? Is there any difference in wall thickness?

- There must be a difference. There is a distinction between rice weight and wall thickness. For example, Jing Teng Aluminum CompanyJT-8-5050W meters weight is 3.25KG,,JT-10-5050 meters weight is 2.95KG. Specific parameters, you can go to consult the next business

- Q: This question asks for a list of various materials that are used in the production of aluminum profiles.

- <p>Aluminum profiles are primarily made from aluminum alloys, which are composed of aluminum combined with other elements to enhance their properties. Common materials used include 6063 aluminum alloy, known for its excellent extrudability and weldability, making it ideal for a wide range of applications. 6061 aluminum alloy is also used for its high strength and good corrosion resistance, suitable for structural components. Other alloys such as 6082 and 7075 are utilized for their superior strength-to-weight ratios, often found in aerospace and automotive industries. Additionally, aluminum profiles may incorporate materials like magnesium, silicon, copper, and manganese to achieve specific mechanical properties or corrosion resistance tailored to particular applications.</p>

- Q: Are aluminum profiles suitable for gym equipment?

- Yes, aluminum profiles are suitable for gym equipment. Aluminum is a lightweight and durable material that can withstand heavy use and provide excellent structural support. Its strength-to-weight ratio makes it ideal for gym equipment as it allows for easy maneuverability while still maintaining stability and durability. Additionally, aluminum is resistant to corrosion, making it suitable for environments with high humidity or moisture levels, such as gyms or fitness centers. The versatility of aluminum profiles also enables the customization of gym equipment to fit specific needs and requirements. Overall, aluminum profiles offer numerous benefits for gym equipment, making them a suitable choice for fitness facilities.

- Q: Are aluminum profiles suitable for conveyor rollers?

- Conveyor rollers can benefit from the use of aluminum profiles. Aluminum, known for its lightweight and durability, offers several advantages for conveyor systems. Firstly, the strength-to-weight ratio of aluminum profiles is outstanding, making them an ideal choice for conveyor rollers. They possess enough strength to handle the weight of transported materials while being light enough to reduce the overall weight of the conveyor system. This results in energy savings and easier installation and maintenance. Additionally, aluminum profiles exhibit excellent resistance to corrosion, which is crucial for conveyor systems operating in harsh environments, such as those exposed to moisture or chemicals. This corrosion resistance ensures the longevity and reliability of the conveyor rollers, reducing the need for maintenance and associated costs. Furthermore, aluminum profiles can be easily customized and fabricated to meet specific requirements of the conveyor system. They can be extruded into various shapes and sizes, allowing for the creation of conveyor rollers that perfectly match the application's needs. This versatility makes aluminum profiles adaptable and suitable for a wide range of conveyor systems in industries like manufacturing, packaging, and logistics. Moreover, aluminum is highly sustainable as it can be 100% recycled, making it an environmentally friendly choice for conveyor rollers. By utilizing aluminum profiles, companies can contribute to their sustainability goals and decrease their carbon footprint. In conclusion, aluminum profiles are indeed a suitable option for conveyor rollers because of their lightweight, durable, corrosion-resistant, customizable, and sustainable characteristics.

- Q: What are the different sizes and dimensions of aluminum profiles?

- The different sizes and dimensions of aluminum profiles can vary greatly depending on the specific application and manufacturer. They can range from small, narrow profiles with dimensions of a few millimeters to larger, wider profiles with dimensions of several inches or more. The length of the profiles can also vary, typically ranging from a few feet to several meters.

- Q: This question asks about the impact of aluminum profiles on the sound insulation properties of a building.

- <p>Aluminum profiles can significantly affect the sound insulation of a building. They are often used in construction for their strength and lightweight properties. However, aluminum is a good conductor of sound, which can lead to sound transmission through the building structure. To enhance sound insulation, aluminum profiles are often combined with soundproofing materials such as acoustic foam or rubber seals. These materials help to absorb or block sound waves, reducing noise transmission. Additionally, the design and installation of aluminum profiles can also impact sound insulation; proper sealing and insulation techniques are crucial to minimize sound leakage.</p>

- Q: Can aluminum profiles be an alternative to wood in construction?

- Yes, aluminum profiles can be a viable alternative to wood in construction. Aluminum profiles offer several advantages over wood, making them a popular choice in many construction projects. Firstly, aluminum profiles are lightweight yet strong, allowing for easy handling and installation. This characteristic makes them suitable for various applications, including frames for doors, windows, curtain walls, and partitions. Additionally, aluminum profiles have excellent durability and resistance to weathering, corrosion, and pests, making them a long-lasting and low-maintenance option. Furthermore, aluminum profiles have inherent fire-resistant properties, which can enhance safety in construction. Unlike wood, aluminum does not burn, and it has a high melting point, making it less likely to contribute to the spread of fires. In terms of sustainability, aluminum profiles can offer environmental benefits. Aluminum is a highly recyclable material, meaning that it can be reused and repurposed multiple times without losing its properties. This recyclability reduces the environmental impact associated with construction projects and supports the circular economy. Another advantage of using aluminum profiles is their design versatility. Aluminum can be easily shaped and extruded into various profiles and sizes, allowing for customization and flexibility in architectural designs. This adaptability makes aluminum profiles suitable for both functional and aesthetic purposes in construction. However, it is important to note that aluminum profiles may have higher upfront costs compared to wood. Additionally, the thermal conductivity of aluminum is higher than that of wood, which means that aluminum profiles may require additional insulation to provide optimal thermal performance. In conclusion, aluminum profiles can be a viable alternative to wood in construction due to their lightweight, durability, fire resistance, sustainability, and design versatility. While there may be some considerations regarding cost and thermal conductivity, the benefits of aluminum profiles make them an attractive option for various construction applications.

Send your message to us

20x40mm Aluminum Profiles for Electric Power Engineering Sector

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords