Bosch Aluminum Extrusion Profiles for Construction Application - Aluminum Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Anodizing for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Anodizing for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

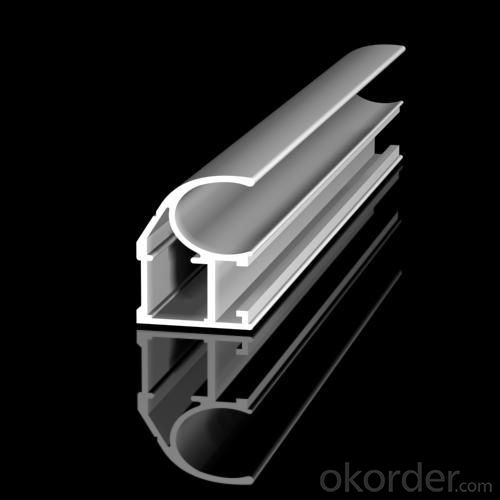

Images of the Aluminium Anodizing for Construction Application:

Aluminium Anodizing for Construction Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks for a list of various uses of aluminum profiles within the construction industry.

- <p>Aluminum profiles have a wide range of applications in the construction industry due to their strength, durability, and lightweight properties. They are used in window and door frames for their resistance to corrosion and ease of maintenance. They are also employed in curtain walls, which are the outer coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are utilized in the construction of scaffolding for their high strength-to-weight ratio, ensuring safety and stability. Additionally, they are used in the manufacturing of modular buildings and prefabricated structures due to their ease of assembly and disassembly. Other applications include roofing systems, flooring structures, and as support beams in various construction projects.</p>

- Q: You need is the extrusion machine section now has Liaoning Zhong Wang Liaoyuan Midas Nanshan aluminum aluminum Hunan Sheng Guangxi jungle SWA South northeast light alloy etc. they have more than 4500 tons of extrusion machine mainly produces large section comprises a track body profile LED lamp shell container ship with large cross section conductor rail section I is a seamless tube a market analyst if you have aluminum industrial material need to be aware of the problem you can consult me as friends.

- 4500T is not very large extrusion machine, a little aluminum factory are generally, in the hope of Liaoning, Qinghai Guoxin, Yun ore has more than 10000 tons of production lines, more than sixty percent domestic aluminum production is Guangdong Foshan, there are several manufacturers have the production line, such as Albert, Jianmei so, need to understand the aluminum things to find the best side to understand

- Q: A curtain wall predecessors?For example, under the transverse frame section, with 6m specifications, why should the material processing and minus 50mm? Insert plate, plate to cut 100mm head? What is the law?

- The column beam rod in the visual profile factory when surface treatment to hang up or put the spraying profile in oxidation tank, in sections at each end of the play of a hole, so that the hook, in the cutting process, in order to avoid the holes will be seen after the installation and so on when will the cutting part of the section cut ends, this is to cause less 50mm. As you said the core insert to reduce 100mm plate plate, this is because the length of processing of these parts is relatively small, some ten centimeters in length, the process if you use a single head saw or double saw large mechanical cutting, base metal processing machinery in a relatively short time finally can not be cut, that is to say the last 100mm~150mm machine cannot continue cutting, it is useless.

- Q: How to sell aluminum profile and accessories, how to find customers online?

- Go to the home network. There are all factories inside

- Q: This question asks for guidance on selecting the appropriate aluminum profiles for a construction project.

- <p>Choosing the right aluminum profiles for your building project involves several steps. First, consider the specific requirements of your project, such as load-bearing capacity, aesthetic preferences, and environmental conditions. Consult with engineers or architects to determine the appropriate strength, size, and shape of the profiles. Next, evaluate the quality of the aluminum, ensuring it meets industry standards for durability and resistance to corrosion. Look for profiles with good thermal insulation properties and UV resistance to maintain performance over time. Finally, consider the cost-effectiveness and availability of the profiles, as well as the ease of installation and maintenance. Always opt for reputable suppliers to ensure you receive high-quality products that meet your project's needs.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials commonly used for roofing, focusing on their characteristics and performance.

- <p>Aluminum profiles for roofing are known for their durability, corrosion resistance, and lightweight nature. Compared to materials like steel, they are less prone to rust and offer a longer lifespan with minimal maintenance. When compared to traditional materials like wood or clay tiles, aluminum profiles are more resistant to weathering and do not rot or warp. They also have a high strength-to-weight ratio, making them ideal for structures that require lighter roofing materials. Additionally, aluminum profiles can be easily recycled, contributing to sustainability efforts. However, they may not offer the same aesthetic appeal as traditional materials and can be more expensive upfront.</p>

- Q: Are aluminum profiles durable?

- Yes, aluminum profiles are highly durable.

- Q: What are aluminum profiles used for?

- Aluminum profiles are commonly used in construction, manufacturing, and industrial applications. They are used for framing structures, such as doors, windows, and curtain walls, providing strength and durability while maintaining a lightweight design. Additionally, aluminum profiles are used in the production of machinery, electrical enclosures, automotive parts, and various consumer products, due to their corrosion resistance, heat conductivity, and versatility in shaping.

- Q: Is it possible to incorporate recycled aluminum extrusions into a construction project?

- <p>Yes, you can use recycled aluminum extrusions in your building project. Recycled aluminum is not only environmentally friendly but also offers the same strength and durability as new aluminum. It is commonly used in construction for framing, window and door profiles, and structural components. Ensure that the recycled aluminum meets the required industry standards for your project to guarantee quality and performance.</p>

- Q: Are aluminum profiles suitable for balcony railings?

- Indeed, balcony railings can be effectively made using aluminum profiles. Aluminum is a favored material for balcony railings because it possesses qualities such as resilience, robustness, and minimal upkeep requirements. Its resistance to rust and corrosion makes it exceedingly appropriate for outdoor applications. Moreover, aluminum profiles can be effortlessly tailored and molded to match any desired design or architectural style. Although lightweight, they offer ample strength to ensure necessary support and safety for balcony railings. Additionally, aluminum railings are obtainable in a plethora of finishes and colors, providing limitless possibilities for design. On the whole, aluminum profiles are a dependable and fashionable choice for balcony railings.

Send your message to us

Bosch Aluminum Extrusion Profiles for Construction Application - Aluminum Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords