Welding PVC Strip Curtains

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

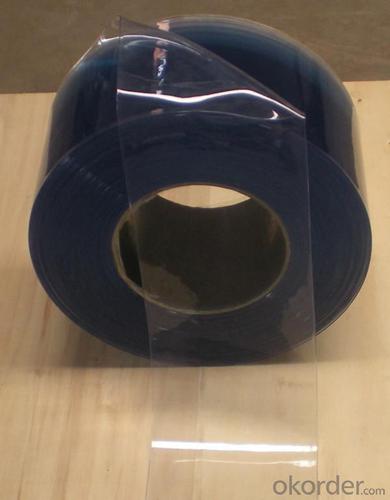

Specifications of Factory Sale Welding PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Factory Sale Welding PVC Strip Curtains

The Welding PVC strip curtain used in workplaces where both bystanders and the welder must be protected against the harmful radiation emitted during welding work.

Welding PVC strip curtain is extremely durable and will stand up to heavy use including a long period of concentrated sparks/splatter.

Welding PVC strip curtain can be used to replace existing welding screens in mobile frames, hung as a sliding partition or used as a durable and solid barrier where access is not required.

Package& Delivery of Factory Sale Welding PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Factory Sale Welding PVC Strip Curtains

Dark green,red,black

Data sheet of Factory Sale Welding PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: Can plastic parts in home appliances be damaged by exposure to sunlight?

- Yes, plastic parts in home appliances can be damaged by exposure to sunlight. Sunlight contains ultraviolet (UV) rays that can cause plastic to become brittle, fade in color, warp, or crack over time. Therefore, it is advisable to protect home appliances with plastic parts from direct sunlight to maintain their longevity and functionality.

- Q: How can I prevent discoloration or yellowing of plastic parts in home appliances?

- There are a few steps you can take to prevent discoloration or yellowing of plastic parts in home appliances. Firstly, avoid exposing the plastic to direct sunlight or heat sources as this can cause fading or yellowing. Secondly, regularly clean the plastic parts using mild soap and water, avoiding harsh chemicals that can potentially damage the plastic. Additionally, consider applying a protective coating or using a plastic polish to maintain the plastic's original appearance. Finally, storing the appliances in a cool, dry place when not in use can also help prevent discoloration.

- Q: How does plastic impact the overall ease of programming and settings of home appliances?

- Plastic has minimal impact on the overall ease of programming and settings of home appliances. The primary role of plastic in appliances is to provide a lightweight and durable casing for the internal components. It does not directly affect the programming or settings functionality. The ease of programming and settings is determined by the design and functionality of the control panel, software, and user interface, which are separate from the material used for the appliance's casing.

- Q: Can plastic home appliances be safely used in households with allergies or sensitivities?

- Yes, plastic home appliances can be safely used in households with allergies or sensitivities. Most plastic appliances are made from materials that are hypoallergenic and do not release harmful substances into the air. However, it is always recommended to check the product labels and choose appliances that are specifically designed for allergy-sensitive individuals or have been certified as allergy-friendly. Additionally, regular cleaning and maintenance of the appliances can help minimize any potential allergens or irritants.

- Q: Can plastic home appliances be easily repaired?

- No, plastic home appliances are generally not easily repaired as they often have complex designs and are not designed to be easily disassembled or repaired.

- Q: How do plastic home appliances compare in terms of energy efficiency?

- Plastic home appliances vary in terms of energy efficiency depending on their design, construction, and usage. While plastic materials can contribute to energy savings due to their lightweight nature, the overall energy efficiency of a plastic appliance is determined by factors such as the efficiency of the components, insulation, and energy-saving features. Therefore, it is essential to consider the specific model and brand when comparing the energy efficiency of plastic home appliances.

- Q: What are the typical thicknesses of home appliance plastics?

- The typical thicknesses of home appliance plastics can vary depending on the specific appliance and its components. However, in general, they range from around 1-3 millimeters for smaller parts like buttons or knobs to 4-6 millimeters for larger components such as panels or housings.

- Q: How does the chemical compatibility of plastic affect the performance of home appliances?

- The chemical compatibility of plastic plays a crucial role in determining the performance of home appliances. Plastics used in appliances need to be compatible with the chemicals or substances they come into contact with, such as cleaning agents or food. If the plastic is not chemically compatible, it may react with these substances, leading to degradation, discoloration, or even the release of harmful substances. This can not only affect the aesthetics of the appliance but also compromise its functionality and lifespan. Therefore, ensuring the chemical compatibility of plastic is essential for maintaining the performance and durability of home appliances.

- Q: What are the considerations for using dishwasher-safe plastic in home appliances?

- When using dishwasher-safe plastic in home appliances, there are a few considerations to keep in mind. Firstly, it is important to ensure that the plastic is indeed labeled as dishwasher-safe, as not all types of plastic can withstand the high temperatures and harsh detergents used in dishwashers. Secondly, it is crucial to follow the manufacturer's instructions regarding temperature limits and cycle options to prevent damage to the plastic. Additionally, it is advisable to avoid using abrasive scrubbers or harsh chemicals that may degrade the plastic over time. Regular inspection of the plastic for any signs of wear or damage is also recommended to ensure its continued safety and effectiveness.

- Q: What are the considerations for using heat-insulating plastic in home appliances?

- There are several considerations when using heat-insulating plastic in home appliances. Firstly, the plastic used should have a high thermal resistance to effectively insulate heat and prevent it from escaping the appliance. Additionally, the plastic should be durable and resistant to high temperatures to avoid melting or deforming over time. It is also important to ensure that the plastic used is non-toxic and safe for use in home appliances, as it may come into contact with food or other sensitive materials. Finally, the cost and availability of the heat-insulating plastic should also be taken into consideration when deciding whether to use it in home appliances.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1991 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 40.00% Southeast Asia 15.00% Mid East 10.00% South America 5.00% Southern Europe 5.00% Northern Europe 5.00% Western Europe 5.00% Oceania 5.00% Africa 5.00% Eastern Europe 5.00% North America |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Welding PVC Strip Curtains

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords