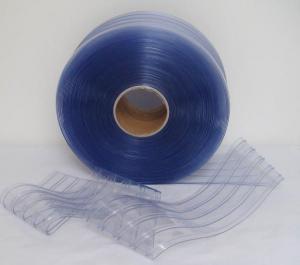

Anti Insect PVC Strip Curtain

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Anti-insect PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Anti-insect PVC Strip Curtains

Windows in commercial food preparation areas need to comply with the latest food and Hygiene Regulations by fitting a screen which prevents the entry of insects, birds and other infestations. Insect-Proof PVC strip curtain is an ideal solution for anywhere that insects aren’t welcome. Insect proof PVC strip curtain made with a specially formulated repellent material that wards off insects. Sanitation authorities are highly concerned with the hygiene conditions of food and drug handling areas.

Ideal solutions for

- Back doors of restaurants

- Personnel doors at commercial and manufacturing locations

- Open air concessions at parks, sports arenas and other outdoor facilities

- Any open area where flying insects are a pest

Package& Delivery of Anti-insect PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Anti-insect PVC Strip Curtains

Yellow is the only color available in proof insect. It emits special light which dispels insects.

- Q: What are the considerations for using recycled plastic in home appliance components?

- Some considerations for using recycled plastic in home appliance components include the quality and purity of the recycled plastic, its compatibility with the appliance's function and durability requirements, the cost-effectiveness of using recycled plastic compared to virgin plastic, and the environmental benefits of reducing plastic waste and promoting a circular economy. Additionally, the availability and accessibility of a consistent supply of recycled plastic and the potential for consumer acceptance and perception of products made with recycled plastic are important factors to consider.

- Q: How does the new Juicer remove the plastic flavor of the fuselage?

- Pay attention to using ah..1. You can wash it with Taomi shui..2. If it still tastes, rub it with alcohol and rinse it with water.

- Q: Are plastic components in home appliances recyclable?

- Yes, plastic components in home appliances are generally recyclable. However, it is important to check with your local recycling facilities to ensure they accept these materials and to follow their specific guidelines for proper recycling.

- Q: Can plastic home appliances be easily repaired?

- Plastic home appliances can generally be easily repaired depending on the extent of the damage and availability of spare parts. However, some appliances may have complex internal components that might require professional expertise for repair.

- Q: What glue does the hard plastic bond with?

- HY-302ABPP glue is mainly used in all kinds of plastic products, PP/PE/POM/, nylon and other kinds of difficult to glue plastic adhesive, requiring high products, different materials, rapid adhesion between each other, Super Sticky relay.

- Q: Are there any specific cleaning products that should be avoided on plastic surfaces of home appliances?

- Yes, there are certain cleaning products that should be avoided on plastic surfaces of home appliances. Avoid using harsh chemicals such as bleach, ammonia, or abrasive cleaners as they can cause discoloration, cracking, or damage to the plastic. Instead, opt for mild soapy water or non-abrasive cleaners specifically formulated for plastic surfaces.

- Q: How do plastic home appliances compare in terms of noise levels?

- Plastic home appliances generally have lower noise levels compared to their metal counterparts. The plastic material helps to dampen vibrations and reduce noise transmission, resulting in quieter operation. However, noise levels can still vary depending on the specific appliance and its design features, so it is recommended to check the product specifications for accurate information on noise levels.

- Q: Are plastic home appliances resistant to electrical shocks or accidents?

- No, plastic home appliances are not inherently resistant to electrical shocks or accidents. The resistance to electrical shocks or accidents depends on the design, construction, and materials used in the appliance. While some plastic appliances may have safety features and insulation to protect against electrical shocks, it is essential to ensure that they meet safety standards and carry appropriate certifications.

- Q: Are there any specific regulations or standards regarding the use of food-grade plastic in home appliances?

- Yes, there are specific regulations and standards in place for the use of food-grade plastic in home appliances. These regulations ensure that the plastic used in contact with food is safe and does not leach harmful chemicals. Standards such as the FDA's Food Contact Notification (FCN) program and the European Union's Regulation (EC) 1935/2004 provide guidelines and approval processes for manufacturers to comply with. These regulations help protect consumers by ensuring that food-grade plastics meet the necessary safety requirements.

- Q: Are plastic home appliances resistant to electromagnetic interference?

- No, plastic home appliances are not typically resistant to electromagnetic interference.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Insect PVC Strip Curtain

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches