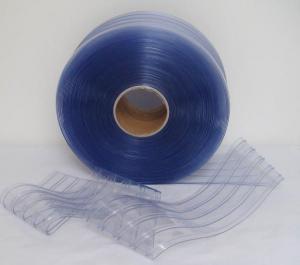

Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

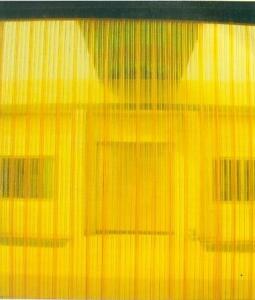

Applications of Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

Package& Delivery of Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

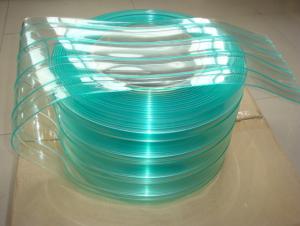

Colors of Anti-static PVC Strip Curtains

Green,Clear.

Data sheet of Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: Are there any safety concerns with plastic parts in electric steamers?

- Yes, there can be safety concerns with plastic parts in electric steamers. Plastic parts may release harmful chemicals when exposed to high temperatures, posing health risks. Additionally, plastic parts may not be as durable or heat-resistant as other materials, potentially leading to melting, warping, or even fire hazards. It is important to choose electric steamers with high-quality, food-grade, and heat-resistant plastic parts to minimize safety concerns.

- Q: Are there any specific guidelines for recycling plastic parts from home appliances?

- Yes, there are specific guidelines for recycling plastic parts from home appliances. It is recommended to check with your local recycling center or municipality for specific instructions. Generally, plastic parts should be separated from other materials, cleaned, and sorted according to their resin codes. Some centers may require you to remove any non-plastic components, such as screws or wires. It's essential to follow the guidelines to ensure proper recycling and minimize environmental impact.

- Q: How does the electrical insulation properties of plastic used in home appliances affect their safety?

- The electrical insulation properties of plastic used in home appliances play a crucial role in ensuring their safety. Plastic materials with good insulation properties prevent the flow of electric current, reducing the risk of electrical shocks or short circuits. By effectively isolating electrical components, plastic insulation helps to safeguard users from potential electric hazards. Additionally, plastic insulation can provide protection against moisture and chemicals, enhancing the durability and overall safety of home appliances.

- Q: Can plastic parts in home appliances be customized or personalized?

- Yes, plastic parts in home appliances can be customized or personalized. Plastic is a highly versatile material that can be easily molded or modified to meet specific design requirements. This allows manufacturers to create unique and customized plastic parts for home appliances, whether it's changing the color, adding logos, or modifying the shape to fit individual preferences.

- Q: How does the chemical compatibility of plastic used in home appliances affect their resistance to corrosion?

- The chemical compatibility of plastic used in home appliances plays a crucial role in determining their resistance to corrosion. When the plastic is not chemically compatible with the substances it comes into contact with, it can lead to chemical reactions that corrode the appliance. On the other hand, if the plastic is chemically resistant to the substances it encounters, it acts as a protective barrier, preventing corrosion from occurring. Therefore, choosing the right plastic with good chemical compatibility is essential for ensuring the longevity and resistance to corrosion of home appliances.

- Q: How does plastic contribute to the insulation properties of home appliances?

- Plastic contributes to the insulation properties of home appliances by providing a barrier that helps to reduce heat transfer. Its low thermal conductivity helps to prevent heat loss or gain, making appliances more energy efficient. Additionally, plastic is a good electrical insulator, reducing the risk of electrical shock and ensuring the safety of users.

- Q: What are the considerations for choosing the appropriate plastic color for an appliance?

- There are several considerations for choosing the appropriate plastic color for an appliance. One important factor is the aesthetic appeal and overall design of the appliance. The color should align with the brand image and target audience preferences. Additionally, the practicality and functionality of the color should be considered. For example, a light-colored plastic may show dirt and stains easily, while a dark-colored plastic may absorb heat. The durability and longevity of the color should also be assessed, as it should be resistant to fading, scratching, and other forms of wear and tear. Finally, any specific industry regulations or standards related to the appliance may also influence the choice of plastic color.

- Q: How long does plastic in home appliances typically last before it starts to degrade?

- The lifespan of plastic in home appliances can vary depending on several factors such as the quality of the plastic, the conditions it is exposed to, and the specific appliance. However, on average, plastic in home appliances can last for several years, typically around 5 to 10 years, before it starts to degrade.

- Q: What are the considerations for using heat-insulating plastic in home appliances?

- There are several considerations for using heat-insulating plastic in home appliances. Firstly, the plastic should have a high thermal resistance to effectively insulate heat and prevent it from escaping or entering the appliance. Additionally, the plastic should be able to withstand high temperatures without deforming or melting, ensuring the appliance's safety and longevity. It is also important to consider the overall cost-effectiveness of the plastic, as well as its environmental impact during production and disposal. Finally, the aesthetic appeal and compatibility of the plastic with the appliance design should be considered to maintain a visually appealing and cohesive look.

- Q: How does plastic contribute to the overall convenience of home appliances?

- Plastic contributes to the overall convenience of home appliances by providing lightweight, durable, and flexible components that make appliances easier to handle, transport, and use. It also allows for the manufacturing of sleek and stylish designs, as well as the incorporation of various features and functionalities. Furthermore, plastic is resistant to corrosion and can be easily molded into complex shapes, enabling the creation of intricate appliance parts and facilitating efficient production processes.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords