Welding PVC Strip Curtains in Dark Green Colors

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

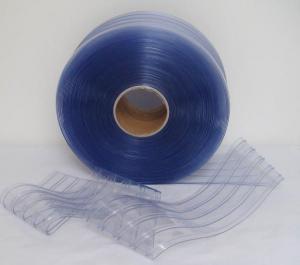

Specifications of Welding PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Welding PVC Strip Curtains

The Welding PVC strip curtain used in workplaces where both bystanders and the welder must be protected against the harmful radiation emitted during welding work.

Welding PVC strip curtain is extremely durable and will stand up to heavy use including a long period of concentrated sparks/splatter.

Welding PVC strip curtain can be used to replace existing welding screens in mobile frames, hung as a sliding partition or used as a durable and solid barrier where access is not required.

Package& Delivery of Welding PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Welding PVC Strip Curtains

Dark green,red,black

Data sheet of Welding PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: How does the chemical inertness of plastic affect the safety of home appliances?

- The chemical inertness of plastic plays a crucial role in ensuring the safety of home appliances. Since plastic is resistant to chemical reactions and does not readily react with other substances, it helps prevent the release of harmful chemicals or toxins into the environment or food items stored in appliances. This inertness reduces the risk of contamination, making plastic a safe choice for housing electrical components and food storage in home appliances.

- Q: How does plastic contribute to the overall ease of use of home appliances?

- Plastic contributes to the overall ease of use of home appliances by providing lightweight and durable components that make appliances easier to handle and transport. Plastic parts are often designed to be ergonomic, allowing for comfortable grips and easy maneuverability. Additionally, plastic is a versatile material that can be molded into various shapes and sizes, enabling manufacturers to create user-friendly designs and streamline the functionality of home appliances.

- Q: Can plastic parts in air purifiers release chemicals into the air?

- Yes, plastic parts in air purifiers can release chemicals into the air. Some plastic materials used in air purifiers may contain volatile organic compounds (VOCs), which can off-gas and potentially pollute the air. It is important to choose air purifiers with high-quality, low-emission plastic components to minimize any potential release of harmful chemicals.

- Q: How do plastic parts in fans and heaters handle constant temperature changes?

- Plastic parts in fans and heaters are designed to handle constant temperature changes by using materials that have a high thermal stability. These materials can withstand a wide range of temperatures without deforming or deteriorating. Additionally, the components are often engineered with thermal expansion and contraction in mind, allowing them to accommodate the changes without causing any damage to the overall structure or performance of the fan or heater.

- Q: Can home appliance plastics be easily molded into desired shapes and forms?

- Yes, home appliance plastics can be easily molded into desired shapes and forms through various molding techniques such as injection molding, blow molding, and rotational molding. These processes allow for precise shaping and customization of the plastics to meet specific design requirements.

- Q: Can plastic parts in home appliances be easily modified or repaired by consumers themselves?

- No, plastic parts in home appliances are typically not easily modified or repaired by consumers themselves. They often require specialized tools, knowledge, and skills to effectively repair or modify plastic components. It is generally recommended to seek professional assistance or contact the manufacturer for any repairs or modifications to ensure safety and proper functioning of the appliance.

- Q: Can plastic home appliances be easily operated and controlled?

- Yes, plastic home appliances can be easily operated and controlled. The use of plastic in the manufacturing of appliances allows for lightweight and user-friendly designs. Additionally, the incorporation of modern technologies and intuitive control interfaces further enhances the ease of operation for users.

- Q: What are the main considerations in choosing the water resistance of plastic for home appliances?

- The main considerations in choosing the water resistance of plastic for home appliances include the intended use and environment of the appliance, the level of exposure to water or moisture, the durability and lifespan required, and the overall cost-effectiveness.

- Q: Can plastic parts in coffee makers resist staining and discoloration over time?

- Yes, plastic parts in coffee makers can generally resist staining and discoloration over time. However, it is important to note that the extent of resistance may vary depending on the quality of the plastic used and the maintenance practices followed. Regular cleaning and proper care can help preserve the appearance of plastic parts in coffee makers and prevent staining or discoloration.

- Q: Are there any specific guidelines for using home appliances with plastic parts in environments with high electromagnetic interference?

- Yes, there are specific guidelines for using home appliances with plastic parts in environments with high electromagnetic interference. It is recommended to use appliances with plastic parts that are designed and certified to meet electromagnetic compatibility (EMC) standards. These standards ensure that the appliances can operate safely and reliably in high electromagnetic interference environments. Additionally, it is advisable to keep such appliances away from sources of high electromagnetic fields or use shielding techniques to minimize interference.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Welding PVC Strip Curtains in Dark Green Colors

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches