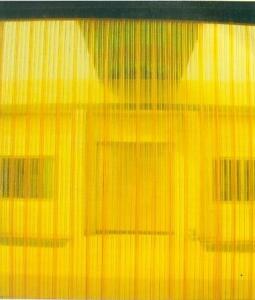

Anti Static PVC Strip Curtains in Green Color

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory-sale Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Factory-sale Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

Package& Delivery of Factory-sale Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale Anti-static PVC Strip Curtains

Green,Clear.

Data sheet of Factory-sale Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: How do home appliance plastics impact the overall design and aesthetics of the appliance?

- Home appliance plastics play a significant role in shaping the overall design and aesthetics of the appliance. These plastics offer versatility in terms of colors, finishes, and textures, allowing manufacturers to create appliances that seamlessly blend with various interior styles. Additionally, plastics enable the creation of sleek and streamlined designs, resulting in modern and visually appealing appliances. Furthermore, the use of durable and high-quality plastics ensures that appliances maintain their aesthetic appeal and functionality over time.

- Q: Are all home appliance plastics recyclable?

- No, not all home appliance plastics are recyclable. The recyclability of plastics depends on their type and composition. While some home appliance plastics can be recycled, others may not have a recycling infrastructure in place or may be made from non-recyclable materials. It is important to check the recycling guidelines in your local area to determine which plastics can be recycled.

- Q: How does plastic impact the overall aesthetic appeal of home appliances?

- Plastic impacts the overall aesthetic appeal of home appliances by providing a sleek and modern look. It allows for smooth and clean lines, which enhance the overall design and make appliances visually appealing. Additionally, plastic can be molded into various shapes and colors, giving manufacturers the freedom to create unique and eye-catching designs. However, if not properly designed or finished, plastic can also give an impression of cheapness or lack of durability, which can negatively affect the aesthetic appeal of the appliances.

- Q: Can plastic parts in home appliances be affected by exposure to abrasive materials?

- Yes, plastic parts in home appliances can be affected by exposure to abrasive materials. These materials can cause scratches, wear, and even structural damage to the plastic components, leading to reduced performance and potentially compromising the functionality of the appliance.

- Q: How does the choice of plastic material impact the overall performance of home appliances?

- The choice of plastic material significantly impacts the overall performance of home appliances. The selection of a suitable plastic can determine the durability, strength, and resistance of the appliance to various factors such as heat, chemicals, and impacts. Additionally, the choice of plastic can affect the aesthetics, weight, and cost of the appliance. Therefore, selecting the right plastic material is crucial in ensuring the overall performance and longevity of home appliances.

- Q: Are there any limitations in terms of chemical resistance for plastic parts in home appliances?

- Yes, there are limitations in terms of chemical resistance for plastic parts in home appliances. While plastics are generally resistant to many common household chemicals, they may be prone to damage or degradation when exposed to certain chemicals, such as strong acids, alkalis, solvents, or abrasive cleaners. It is important to consult the manufacturer's guidelines and use compatible cleaning agents to ensure the longevity and performance of plastic parts in home appliances.

- Q: Are there any specific guidelines for using home appliances with plastic parts in dusty environments?

- Yes, there are specific guidelines for using home appliances with plastic parts in dusty environments. It is recommended to regularly clean and remove dust from the appliances to prevent it from accumulating and affecting their performance. Additionally, placing the appliances in enclosed areas or using covers when not in use can help minimize the amount of dust that settles on them.

- Q: Are there any disadvantages of using plastic in home appliances?

- Yes, there are several disadvantages of using plastic in home appliances. Firstly, plastic is not as durable or long-lasting as materials like metal, which can lead to a shorter lifespan for the appliance. Additionally, plastic is prone to cracking, warping, or melting under high temperatures, which can be a safety hazard. Furthermore, the production and disposal of plastic appliances contribute to environmental pollution and waste, as plastic takes a long time to decompose and often ends up in landfills or oceans.

- Q: What's wrong with making tea with a rubber cup?

- In addition to heating the plastic cup will precipitate some chemicals, but also very easy to breed bacteria. Although the plastic surface looks smooth, but in fact there are many gaps, easy to shelter evil people and countenance evil practices. In the office, most people clean the cups only with clean water, and the cups can not be thoroughly cleaned and disinfected. Experts suggest that the office is best to use stainless steel cups or glass, wash every day, it is best to use detergent, and rinse with hot water.

- Q: What are the considerations for using heat-resistant plastic in kitchen appliances?

- When considering the use of heat-resistant plastic in kitchen appliances, several factors need to be taken into account. First and foremost, the plastic material should have a high melting point to withstand the temperatures commonly found in kitchens, such as those used for cooking or baking. It is also important to ensure that the plastic is food-safe and does not release harmful chemicals when exposed to heat. Additionally, the material should be able to maintain its structural integrity, resisting deformation or warping when subjected to high temperatures. Finally, the plastic should be durable and resistant to wear and tear, as kitchen appliances are frequently used and handled.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Static PVC Strip Curtains in Green Color

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords