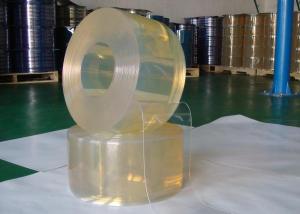

Anti Insect PVC Strip Curtain in Yellow Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory-sale Anti Insect PVC Strip Curtain

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

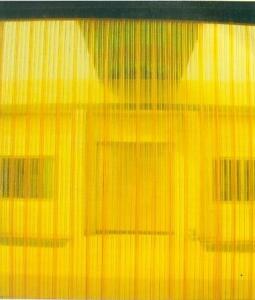

Applications of Factory-sale Anti Insect PVC Strip Curtain

Windows in commercial food preparation areas need to comply with the latest food and Hygiene Regulations by fitting a screen which prevents the entry of insects, birds and other infestations. Insect-Proof PVC strip curtain is an ideal solution for anywhere that insects aren’t welcome. Insect proof PVC strip curtain made with a specially formulated repellent material that wards off insects. Sanitation authorities are highly concerned with the hygiene conditions of food and drug handling areas.

Ideal solutions for

- Back doors of restaurants

- Personnel doors at commercial and manufacturing locations

- Open air concessions at parks, sports arenas and other outdoor facilities

- Any open area where flying insects are a pest

Package& Delivery of Factory-sale Anti Insect PVC Strip Curtain

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale Anti Insect PVC Strip Curtain

Yellow is the only color available in proof insect. It emits special light which dispels insects.

- Q: How do home appliance plastics impact the overall design and aesthetics of the appliance?

- Home appliance plastics play a critical role in shaping the overall design and aesthetics of the appliance. They offer flexibility in terms of color, texture, and finish, allowing manufacturers to create sleek, modern, and visually appealing designs. Additionally, plastics enable the creation of complex shapes and forms, enhancing the functionality and ergonomics of the appliance. The use of plastics also contributes to lightweight construction, making appliances easier to handle and install. Overall, home appliance plastics significantly influence the design and aesthetics, elevating the consumer experience.

- Q: PE what kind of glue do you use for acrylic boards?

- Different materials with the glue is not the same as ordinary instant glue, AB glue, silicone can. If it's PP, PE, use a special glue.

- Q: How do plastic home appliances compare in terms of recyclability rates?

- Plastic home appliances have varying recyclability rates depending on their composition and design. While some appliances are made of highly recyclable plastics, others may incorporate mixed materials or complex components that make recycling more challenging. Additionally, the availability and accessibility of recycling facilities also affect the overall recyclability rates. Therefore, it is important to consider the specific appliance and local recycling capabilities when assessing their recyclability.

- Q: How do home appliance plastics affect the overall design and aesthetics of the appliance?

- Home appliance plastics play a crucial role in shaping the overall design and aesthetics of the appliance. They offer flexibility in terms of molding, allowing for sleek and modern designs that can complement any home decor. The choice of plastics also affects the appliance's color options, texture, and transparency. Additionally, plastics can be made to mimic other materials like metal or glass, giving appliances a premium look at a more affordable cost. Overall, the selection of home appliance plastics greatly influences the visual appeal and functionality of the product.

- Q: How long do plastic components in home appliances typically last?

- The lifespan of plastic components in home appliances can vary depending on several factors such as usage, maintenance, and quality of materials. However, on average, plastic components in home appliances tend to last anywhere from 5 to 15 years.

- Q: How can I clean plastic parts in my home appliances without damaging them?

- To clean plastic parts in your home appliances without causing any damage, first, unplug the appliance and remove any detachable parts. For general cleaning, use a mixture of mild dish soap and warm water. Gently scrub the plastic parts using a soft sponge or cloth, avoiding abrasive materials or harsh chemicals. Rinse thoroughly and ensure they are completely dry before reassembling and plugging in the appliance.

- Q: Can plastic turntable plates in microwaves crack or become damaged over time?

- Yes, plastic turntable plates in microwaves can crack or become damaged over time. The constant exposure to heat and the weight of the food being heated can weaken the plastic, leading to cracks or breakage. It is important to handle and maintain the turntable plate carefully to avoid any potential damage.

- Q: What considerations are taken into account when selecting the color of plastic parts in home appliances?

- When selecting the color of plastic parts in home appliances, several considerations are taken into account. Firstly, the color should align with the overall design and aesthetic of the appliance, ensuring it complements the intended style and target market. Secondly, the color choice may be influenced by the psychological impact it has on consumers, as certain colors can convey specific emotions or create a sense of trust and reliability. Additionally, practical aspects such as color durability, resistance to fading or staining, and ease of maintenance are important factors when choosing the color of plastic parts in home appliances.

- Q: Are there any specific safety considerations when using plastic in home appliances?

- Yes, there are specific safety considerations when using plastic in home appliances. It is important to ensure that the plastic used is heat resistant and non-toxic, as some plastics may release harmful substances when exposed to high temperatures. Additionally, the plastic should be durable and able to withstand mechanical stress to prevent breakage or malfunctioning. Regular maintenance and proper disposal of plastic parts are also crucial to prevent any hazards or environmental pollution.

- Q: How does the choice of plastic in humidifiers affect moisture output?

- The choice of plastic in humidifiers can affect moisture output in several ways. Firstly, the type of plastic used can determine its resistance to heat and humidity. Certain plastics may withstand high temperatures and humidity levels better than others, resulting in more efficient and consistent moisture output. Additionally, the quality and composition of the plastic can impact the overall performance of the humidifier. If the plastic is of low quality or prone to degradation, it may release harmful chemicals or particles into the air, reducing the effectiveness and safety of the device. Furthermore, the design and construction of the humidifier, including the type of plastic used in key components such as the water tank or misting mechanism, can influence how effectively moisture is dispersed. A well-designed humidifier with high-quality plastic components is more likely to provide consistent and optimal moisture output. In conclusion, the choice of plastic in humidifiers plays a vital role in determining the device's durability, efficiency, and overall moisture output.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Insect PVC Strip Curtain in Yellow Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches