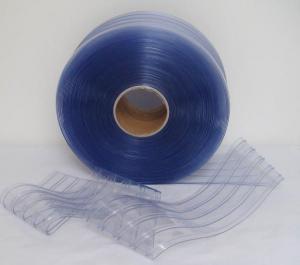

PVC Strip Door Curtain Used for Warehouse

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Warehouse Use PVC Strip Door Curtain

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Warehouse Use PVC Strip Door Curtain

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Warehouse Use PVC Strip Door Curtain

Wooden pallet,shirnk film according to custom requires.

Colors of Warehouse Use PVC Strip Door Curtain

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: What are the main considerations in choosing the recyclability of plastic for home appliances?

- The main considerations in choosing the recyclability of plastic for home appliances include the type of plastic used, its compatibility with existing recycling processes, the availability of recycling facilities, the demand for recycled plastics in the market, and the environmental impact of recycling versus other disposal methods.

- Q: Are there any specific guidelines for cleaning home appliances with plastic parts?

- Yes, there are specific guidelines for cleaning home appliances with plastic parts. It is generally recommended to use mild soapy water or a non-abrasive cleaner and a soft cloth or sponge to clean the plastic parts. Avoid using harsh chemicals, abrasive cleaners, or scrub brushes that can cause damage or scratches to the plastic surfaces. Additionally, it is important to check the manufacturer's instructions or user manual for any specific cleaning recommendations for your particular appliance.

- Q: How do home appliance plastics contribute to the overall safety of the appliance?

- Home appliance plastics play a crucial role in enhancing the overall safety of appliances. These plastics are designed to be fire-resistant, reducing the risk of ignition and potential fire hazards. Additionally, they are often used to insulate electrical components, preventing electrical shocks and ensuring user safety. Furthermore, these plastics are durable and impact-resistant, protecting internal mechanisms and preventing any potential hazards due to their failure.

- Q: What are the typical thicknesses of home appliance plastics?

- The typical thicknesses of home appliance plastics can vary depending on the specific appliance and its components. However, in general, the plastic parts used in home appliances can range from a few millimeters to several centimeters in thickness.

- Q: How do plastic home appliances compare in terms of noise reduction features?

- Plastic home appliances generally have good noise reduction features due to their ability to absorb vibrations and minimize sound transmission. However, the effectiveness of noise reduction may vary depending on the specific appliance and its design.

- Q: Do home appliance plastics have any electrical conductivity?

- No, home appliance plastics generally do not have electrical conductivity as they are designed to be insulators to prevent electrical currents from passing through them.

- Q: Are there any specific guidelines for recycling or disposing of plastic parts from upgraded home appliances?

- Yes, there are specific guidelines for recycling or disposing of plastic parts from upgraded home appliances. It is recommended to check with local recycling centers or waste management authorities for their specific guidelines. In general, plastic parts should be separated from other materials and recycled separately. If recycling is not an option, they can be disposed of in accordance with local waste disposal regulations.

- Q: How do you clean plastic surfaces on home appliances?

- To clean plastic surfaces on home appliances, you can start by preparing a mixture of mild dish soap and warm water. Use a soft cloth or sponge to dip into the soapy water and gently scrub the plastic surfaces. Ensure not to use abrasive scrubbers or harsh chemicals that can damage the plastic. Rinse the surfaces with clean water and dry them thoroughly with a soft towel.

- Q: Can plastic parts in home appliances be easily recycled through municipal recycling programs?

- Plastic parts in home appliances can generally be recycled through municipal recycling programs, but it may vary depending on local recycling guidelines and the specific type of plastic used in the parts.

- Q: Are there any limitations in terms of pressure resistance for plastic parts in home appliances?

- Yes, there are limitations in terms of pressure resistance for plastic parts in home appliances. Plastic materials used in home appliances have specific pressure ratings that determine their ability to withstand different levels of pressure. Exceeding these pressure limits can result in deformation, cracking, or even failure of the plastic parts. Therefore, it is important to ensure that the pressure exerted on plastic components in home appliances remains within the specified limits to avoid any potential damage.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Door Curtain Used for Warehouse

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords