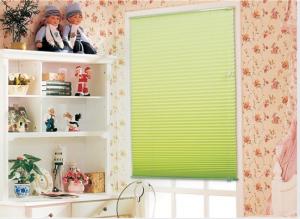

PVC Strip Doors of Different Colors

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High quality PVC Strip Doors

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of High quality PVC Strip Doors

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of High quality PVC Strip Doors

Wooden pallet,shirnk film according to custom requires.

Colors of High quality PVC Strip Doors

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: What are the common plastic components found in air conditioners?

- Some common plastic components found in air conditioners include fan blades, housing panels, condensate drip trays, air ducts, and control knobs.

- Q: What are the main factors that affect the lifespan of plastic parts in home appliances?

- The main factors that affect the lifespan of plastic parts in home appliances include the quality and type of plastic used, exposure to heat and moisture, frequency and intensity of use, maintenance and care, as well as the overall design and construction of the appliance.

- Q: Are there any limitations or drawbacks to using plastic in home appliances?

- Yes, there are limitations and drawbacks to using plastic in home appliances. Firstly, plastic is not as durable as materials like metal or glass, making it more prone to breakage or damage over time. Additionally, certain plastics can be affected by heat, causing them to warp or melt, which can be a safety concern. Moreover, plastic is non-biodegradable and can contribute to environmental pollution, especially when disposed of improperly. Lastly, the production of plastic involves the use of fossil fuels and harmful chemicals, contributing to carbon emissions and environmental degradation.

- Q: What are the typical manufacturing processes for home appliance plastics?

- The typical manufacturing processes for home appliance plastics include injection molding, blow molding, and thermoforming. Injection molding involves injecting molten plastic into a mold cavity and allowing it to cool and solidify, creating the desired shape. Blow molding is used to create hollow plastic parts by blowing air into a molten plastic tube, expanding it to match the shape of the mold. Thermoforming involves heating a plastic sheet and shaping it using a mold and vacuum or pressure, resulting in a formed part. These processes are commonly used in the production of various home appliances such as refrigerators, washing machines, and microwave ovens.

- Q: How does the use of plastic in home appliances impact the overall safety of the appliance?

- The use of plastic in home appliances can impact the overall safety of the appliance both positively and negatively. On one hand, plastic can provide insulation and reduce the risk of electrical hazards. It is also lightweight, making appliances easier to handle and maneuver. Additionally, plastic is non-conductive, which can prevent the transmission of electric shocks. On the other hand, plastic may pose a fire hazard if it is not heat-resistant or if it comes into contact with hot components. Moreover, some plastics may release harmful chemicals when heated, potentially affecting air quality. Overall, the impact of plastic on appliance safety depends on the specific type and quality of plastic used, as well as proper design and manufacturing standards.

- Q: What are the main factors that determine the dimensional stability of plastic parts in home appliances?

- The main factors that determine the dimensional stability of plastic parts in home appliances are the type and quality of the plastic material used, the design and thickness of the part, the molding process and conditions, as well as the post-molding cooling and annealing processes.

- Q: What are the considerations for using fire-resistant plastic in fans and heaters?

- The considerations for using fire-resistant plastic in fans and heaters primarily revolve around safety and performance. Fire-resistant plastic should meet specific industry standards and regulations to ensure it can withstand high temperatures without melting or releasing toxic fumes. It should also be durable and resistant to ignition, minimizing the risk of fires. Additionally, the chosen plastic should not compromise the fan or heater's functionality, airflow, or heat distribution capabilities, ensuring optimal performance while maintaining safety standards.

- Q: How does plastic affect the overall noise levels of home appliances?

- Plastic can have a significant impact on reducing noise levels in home appliances. Its properties, such as its sound-absorbing abilities and ability to dampen vibrations, help to minimize noise produced by the appliance components. By incorporating plastic components or coatings in appliances, manufacturers can effectively reduce noise pollution and enhance the overall acoustic experience for users.

- Q: Are there any health concerns associated with using plastic in home appliances?

- Yes, there are potential health concerns associated with using plastic in home appliances. Certain plastics, such as those containing bisphenol A (BPA) or phthalates, may leach harmful chemicals into food or drinks, especially when exposed to heat or acidic substances. These chemicals have been linked to various health issues, including hormonal disruptions, reproductive problems, and certain cancers. It is advisable to opt for BPA-free or phthalate-free plastics or consider alternatives like glass or stainless steel whenever possible to minimize these risks.

- Q: What adhesive effect is best for plastic and plastic bonding?

- Jujian G-977 ABS special glue is a one component solvent based adhesives with vinyl polymer as the main body. The utility model has the advantages of convenient use, quick positioning, high bonding strength, non-toxic curing agent, etc.. Glue all solid, waterproof, heat-resistant, cold resistant, oil resistance, corrosion resistance, and ABS engineering plastics, for the current bonding ABS, acrylic, PC, PS, GP, AS and other hard plastic works of the best glue.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Doors of Different Colors

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 sets roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches