Welding PVC Strip Curtains in High Quality

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

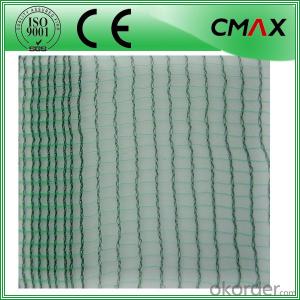

Specifications of High Quality Welding PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of High Quality Welding PVC Strip Curtains

The Welding PVC strip curtain used in workplaces where both bystanders and the welder must be protected against the harmful radiation emitted during welding work.

Welding PVC strip curtain is extremely durable and will stand up to heavy use including a long period of concentrated sparks/splatter.

Welding PVC strip curtain can be used to replace existing welding screens in mobile frames, hung as a sliding partition or used as a durable and solid barrier where access is not required.

Package& Delivery of High Quality Welding PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of High Quality Welding PVC Strip Curtains

Dark green,red,black

Data sheet of High Quality Welding PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q: Can home appliance plastics be easily sanitized to maintain hygiene?

- Yes, home appliance plastics can be easily sanitized to maintain hygiene. Plastics used in home appliances are typically designed to be resistant to chemicals and can be effectively cleaned using mild soap and water, disinfecting wipes, or sanitizing sprays. Regular cleaning and sanitization of home appliance plastics can help eliminate bacteria, viruses, and other contaminants, ensuring a hygienic environment in the home.

- Q: Can home appliance plastics be easily recycled into other plastic products?

- Yes, home appliance plastics can be easily recycled into other plastic products.

- Q: What are the main factors that determine the scratch resistance of plastic parts in home appliances?

- The main factors that determine the scratch resistance of plastic parts in home appliances are the type and quality of the plastic material used, the surface treatment or coating applied, and the external forces or conditions the appliance is exposed to during use and handling.

- Q: How do home appliance plastics contribute to the overall energy efficiency of the appliance?

- Home appliance plastics play a crucial role in enhancing the energy efficiency of the appliance by reducing heat loss, improving insulation, and increasing overall durability. These plastics are often used for insulation purposes, preventing the loss of heat or cold air from appliances such as refrigerators or air conditioners. Additionally, lightweight plastics are employed in manufacturing to reduce the appliance's weight, making it more energy-efficient during transportation and reducing carbon emissions. Furthermore, plastics enable the design of more durable and longer-lasting appliances, minimizing energy consumption associated with manufacturing and disposal. Overall, home appliance plastics significantly contribute to improving energy efficiency, resulting in reduced energy consumption and environmental impact.

- Q: What are some innovations in plastic technology that have impacted home appliance design?

- Some innovations in plastic technology that have impacted home appliance design include the development of lightweight and durable plastics, such as polycarbonate and ABS, which have allowed for sleek and modern designs. Additionally, advancements in plastic molding techniques have enabled the creation of complex shapes and intricate details, enhancing the aesthetic appeal of home appliances. The use of heat-resistant plastics has also revolutionized the design of appliances like coffee makers and toasters, making them safer and more efficient. Moreover, the integration of recycled or biodegradable plastics in appliance manufacturing has contributed to eco-friendly designs and sustainability in the industry.

- Q: How does the transparency or opacity of plastic parts in home appliances affect their functionality?

- The transparency or opacity of plastic parts in home appliances can affect their functionality in several ways. Firstly, transparent plastic parts can allow users to easily monitor and observe the functioning of the appliance. For example, in a blender, transparent housing allows users to see the blending process and ensure that the ingredients are mixed properly. This enhances the user experience and helps in achieving the desired results. Secondly, transparency can also play a role in safety. In appliances like electric kettles or coffee makers, transparent water level indicators allow users to accurately measure the amount of liquid inside, preventing overflows or potential hazards. Additionally, transparency can help users identify any potential issues or malfunctions within the appliance, such as leaks or blockages, leading to timely repairs or replacements. On the other hand, opacity in plastic parts can also be advantageous. In certain appliances, such as dishwashers or washing machines, opaque plastic panels or doors can help conceal the inner workings and protect delicate components from dust, moisture, or accidental damage. This adds to the overall durability and longevity of the appliance. In conclusion, the transparency or opacity of plastic parts in home appliances can greatly impact their functionality, either by enhancing user experience and safety through transparency or by providing protection and durability through opacity.

- Q: How long do home appliance plastics typically last?

- Home appliance plastics typically have a lifespan of 10 to 20 years, depending on usage and maintenance.

- Q: Are there any disadvantages to using plastic in home appliances?

- Yes, there are several disadvantages to using plastic in home appliances. Firstly, plastic is not as durable as other materials like metal or glass, making it more prone to breakage or wear and tear over time. Secondly, plastic can release harmful chemicals when exposed to heat or certain conditions, posing health risks. Additionally, plastic is not biodegradable and contributes to pollution and environmental degradation when not recycled properly. Lastly, the production of plastic appliances requires significant amounts of fossil fuels, contributing to greenhouse gas emissions and climate change.

- Q: Can plastic parts in washing machines be affected by water and detergent?

- Yes, plastic parts in washing machines can be affected by water and detergent. Water and detergent can cause deterioration, warping, discoloration, and weakening of plastic components over time, especially if they are exposed to harsh chemicals or high temperatures. It is important to use compatible detergents and avoid using excessive amounts to minimize the potential damage to plastic parts.

- Q: What are the main considerations in choosing the cost-effectiveness of plastic for home appliances?

- The main considerations in choosing the cost-effectiveness of plastic for home appliances include the initial cost of plastic materials, manufacturing efficiency, durability and lifespan of the appliance, energy efficiency, and the overall cost of maintenance and repairs. Additionally, the environmental impact of plastic production and disposal should also be taken into account when evaluating the cost-effectiveness of using plastic in home appliances.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Welding PVC Strip Curtains in High Quality

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords