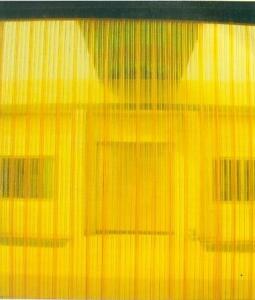

Pvc Strip Curtain Hardware

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 5 Containers Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Strip Curtain Hardware

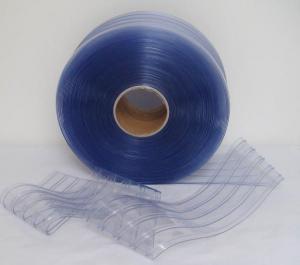

Specifications of PVC Strip Curtain Hardware

1. Rail Size: 1m(length)x25px(thickness)

2. Clip Size:

150mm(w)x1mm(t)

200mm(w)x1mm(t)

300mm(w)x1mm(t)

Material: SS201,SS304,G.I

Application:

Applications of PVC Strip Curtain Hardware

One set of hanger include 3 ways

A. 1m rail, 8sets clips and 24 pcs screws, be applicable for 150mm and 200mm wide PVC strip

B. 1m rail, 6sets clips and 18 pcs screws, be applicable for 200mm and 300mm wide PVC strip

C. 1m rail, 4sets clips and 16 pcs screws, be applicable for 300mm and 400mm wide PVC strip

Package& Delivery of PVC Strip Curtain Hardware

Wooden pallet,Carton box according to custom requires.

Installation of PVC Strip Curtain Hardware

1.Cutting

Measure the size of door and cut the PVC strip curtain accordingly. Make sure the angle is 90 degree; Be carful with the cutter

2. Punch hole

a) Pushing holes in one side of PVC strip curtain

b) 200mm width door curtain need 3 holes

c) 300mm width door curtain need 4 holes

3. Install holders

a) Butt holders to the PVC strip with Screw.

b) Make sure the angle between strip and holders is 90 degree

4.Install hangers

Choose the best tool to punch hole according to the material of wall

- Q: How does plastic impact the overall efficiency of home appliances?

- Plastic can have both positive and negative impacts on the overall efficiency of home appliances. On one hand, plastic components in appliances can help reduce weight, making them easier to handle and transport. Plastic insulation can also improve energy efficiency by reducing heat loss or gain. Additionally, plastic parts are often more durable and resistant to corrosion, leading to longer appliance lifespan. However, excessive use of plastic in appliances can also hinder their efficiency. Poor-quality plastic components may degrade quickly, leading to reduced performance and potential breakdowns. Moreover, plastic casings can impede heat dissipation, causing appliances to overheat, which in turn reduces their efficiency and lifespan. Additionally, plastic waste generated from appliances contributes to environmental issues, including pollution and resource depletion. Hence, it is crucial to strike a balance in using plastic in appliances, prioritizing high-quality materials and eco-friendly practices to minimize negative impacts on efficiency.

- Q: Can plastic home appliances be safely used in households with pets?

- Yes, plastic home appliances can be safely used in households with pets. However, it is important to ensure that the appliances are pet-proofed and kept out of the reach of pets, especially if they have a tendency to chew on things. Additionally, regular cleaning and maintenance of the appliances will help prevent any potential hazards to both pets and humans.

- Q: Are there any limitations in terms of ultraviolet (UV) resistance for plastic parts in home appliances?

- Yes, there are limitations in terms of ultraviolet (UV) resistance for plastic parts in home appliances. Plastic materials used in appliances can degrade and become brittle when exposed to prolonged UV radiation, leading to discoloration, cracking, and reduced performance. To mitigate this, manufacturers often incorporate UV stabilizers or additives into the plastic formulation to enhance its resistance to UV radiation. However, even with these measures, plastic parts may still have a limited lifespan when exposed to intense or continuous UV exposure.

- Q: How does the weight of plastic parts in home appliances affect their functionality?

- The weight of plastic parts in home appliances can affect their functionality in various ways. Firstly, a heavier plastic component may provide better stability and durability, increasing the overall robustness of the appliance. On the other hand, excessive weight can make the appliance cumbersome and difficult to move or handle. Additionally, the weight of plastic parts can impact the energy efficiency of the appliance, as heavier components may require more power to operate. Therefore, finding the right balance between weight and functionality is crucial in designing efficient and user-friendly home appliances.

- Q: Are plastic home appliances compatible with smart home technology?

- Yes, plastic home appliances can be compatible with smart home technology. The material of the appliance does not restrict its compatibility with smart home features, as the integration of smart technology is primarily dependent on the internal components and connectivity options.

- Q: What are the main factors considered when selecting plastic for home appliance production?

- When selecting plastic for home appliance production, the main factors considered are the material's durability, heat resistance, electrical properties, chemical resistance, and cost-effectiveness. Other factors include the plastic's ability to be molded into complex shapes, its aesthetic appeal, and its environmental impact.

- Q: Are there any health concerns associated with using plastic in home appliances?

- Yes, there are potential health concerns associated with using plastic in home appliances. Some types of plastic, such as polycarbonate, can leach harmful chemicals like bisphenol A (BPA) into food or beverages when exposed to heat or acidic conditions. BPA has been linked to various health issues, including hormonal imbalances, reproductive problems, and certain cancers. To minimize these risks, it is advisable to choose appliances made from BPA-free plastics or alternative materials, such as stainless steel or glass.

- Q: How does plastic impact the overall reliability of home appliances?

- Plastic can impact the overall reliability of home appliances in a few ways. Firstly, the use of plastic components in appliances can lead to decreased durability and longevity. Plastic parts may be more prone to wear and tear, resulting in a higher likelihood of breakage or malfunction. Additionally, plastic may not withstand high temperatures or excessive stress as well as other materials, further reducing the reliability of appliances. Furthermore, plastic can contribute to electrical insulation problems or interfere with the proper functioning of components, affecting the overall reliability and performance of home appliances.

- Q: How does the cost of producing home appliances with plastic compare to other materials?

- The cost of producing home appliances with plastic generally tends to be lower compared to other materials such as metal or glass. This is primarily due to the lower cost of raw materials, easier manufacturing processes, and the ability to produce complex shapes and designs more efficiently with plastic. Additionally, plastic appliances often require less maintenance and have a longer lifespan, which can also contribute to their overall cost-effectiveness.

- Q: Are there any specific regulations regarding the use of plastic in home appliances for industrial purposes?

- Yes, there are specific regulations regarding the use of plastic in home appliances for industrial purposes. These regulations vary depending on the country and region. In many cases, there are standards and guidelines that manufacturers must adhere to, specifying the types of plastics that can be used, the levels of certain chemicals allowed, and the overall safety and environmental requirements. These regulations aim to ensure that plastic components used in home appliances meet certain quality, safety, and sustainability criteria.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Pvc Strip Curtain Hardware

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 Sets set

- Supply Capability:

- 5 Containers Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords