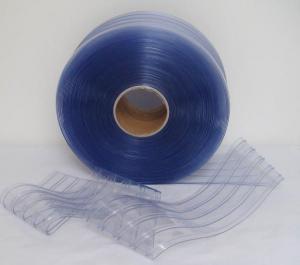

PVC Strip Door Curtain Used for Food Factory

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Best Selling PVC Strip Door Curtain

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Best Selling PVC Strip Door Curtain

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Best Selling PVC Strip Door Curtain

Wooden pallet,shirnk film according to custom requires.

Colors of Best Selling PVC Strip Door Curtain

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q: Are there any fire safety concerns related to plastic components in home appliances?

- Yes, there can be fire safety concerns related to plastic components in home appliances. Plastic is a combustible material that can melt, ignite, or release toxic fumes when exposed to high temperatures or fires. If the plastic components in appliances are not heat-resistant or made of flame-retardant materials, they can contribute to the spread of fire or release harmful gases. Therefore, it is crucial to ensure that home appliances have proper fire safety measures in place and use materials that meet safety standards to minimize the risks associated with plastic components.

- Q: Do home appliance plastics contain harmful chemicals?

- Some home appliance plastics may contain harmful chemicals, such as phthalates or BPA, which have been linked to health concerns. However, not all home appliance plastics are necessarily harmful, as safety regulations and standards vary. It is important to research and choose appliances that are certified to be free from harmful chemicals or opt for alternative materials whenever possible.

- Q: Are there any health concerns associated with plastic in home appliances?

- Yes, there are potential health concerns associated with plastic in home appliances. Plastics can contain harmful chemicals like phthalates and bisphenol A (BPA), which can leach into food or water when heated or stored for long periods. These chemicals have been linked to various health issues, including hormonal disruptions, reproductive problems, and certain cancers. It is advisable to choose appliances made from BPA-free and food-grade plastics or opt for alternatives like stainless steel or glass to minimize potential health risks.

- Q: What are the typical lifespan expectations for home appliance plastics?

- The typical lifespan expectations for home appliance plastics can vary depending on the specific appliance and its usage. However, most home appliance plastics are designed to last for several years to a decade or more with proper care and maintenance.

- Q: How do home appliance plastics affect the overall noise levels of the appliance?

- Home appliance plastics can have a significant impact on the overall noise levels of the appliance. Plastics used in the construction of home appliances can either absorb or reflect sound waves, affecting how noise is transmitted. The type and quality of plastics used, as well as their thickness and design, can determine the level of noise insulation provided by the appliance. Additionally, vibrations caused by the appliance's motor or other moving parts can be dampened or amplified by the plastic materials used, further influencing the overall noise levels.

- Q: How does the thermal conductivity of plastic used in home appliances affect their energy efficiency?

- The thermal conductivity of plastic used in home appliances directly affects their energy efficiency. Plastic materials with low thermal conductivity act as insulators, preventing heat transfer between the internal components of the appliance and the surrounding environment. This insulation property helps to maintain the desired temperature inside the appliance, reducing the amount of energy needed for heating or cooling. Therefore, home appliances made with low thermal conductivity plastic are more energy-efficient compared to those made with materials that have higher thermal conductivity.

- Q: Can plastic parts in home appliances be easily cleaned with eco-friendly cleaning products?

- Yes, plastic parts in home appliances can generally be easily cleaned with eco-friendly cleaning products. These products are designed to effectively remove dirt and grime from various surfaces, including plastic, while being safe for the environment. However, it is important to read the instructions on the cleaning products and follow the recommended usage to ensure proper cleaning.

- Q: What are the main challenges in recycling plastic parts from home appliances?

- One of the main challenges in recycling plastic parts from home appliances is the variety of plastic types used in their manufacturing. Different types of plastic require different recycling processes, making it difficult to effectively sort and recycle these parts. Additionally, the presence of other materials such as metals and electronics further complicates the recycling process. Furthermore, the lack of awareness and infrastructure for proper collection and recycling of these appliances poses a significant challenge in recycling plastic parts from home appliances.

- Q: Are there any concerns with using plastic in appliances that emit electromagnetic radiation?

- Yes, there are concerns with using plastic in appliances that emit electromagnetic radiation. Plastic, being an insulator, can potentially trap and amplify electromagnetic radiation within the appliance, increasing the risk of heat build-up and potential damage to the device. Moreover, certain plastics may not be able to withstand high temperatures generated by electromagnetic radiation, leading to melting or deformation of the appliance's components. Additionally, plastic materials may release harmful chemicals when exposed to electromagnetic radiation, posing health risks to users. Therefore, careful consideration should be given to the choice of plastic materials used in such appliances to ensure safety and performance.

- Q: How do plastic home appliances compare in terms of noise levels?

- Plastic home appliances generally have lower noise levels compared to their metal counterparts. The plastic material helps to dampen vibrations and reduce noise transmission, resulting in quieter operation. However, noise levels can still vary depending on the specific appliance and its design features, so it is recommended to check the product specifications for accurate information on noise levels.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Door Curtain Used for Food Factory

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches