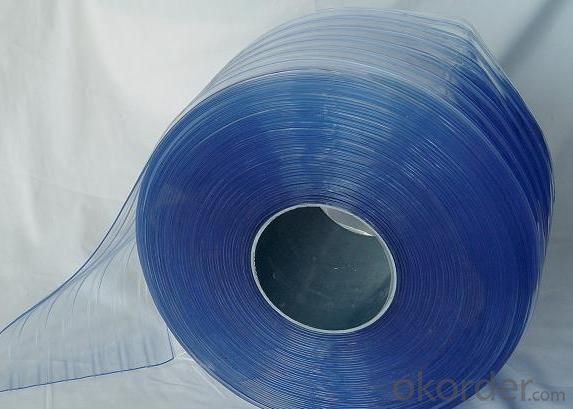

Polar PVC Strips Curtains in Blue Color

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Polar PVC Strip Curtains

Application tempt range: -40℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Polar PVC Strip Curtains

Polar PVC strip curtain remain highly soft even at 40 Celsius below zero, allowing easy passing of people, vehicles and goods and effectively preventing loss of cold air. Polar PVC sheet is a good choice for save power because they do not contain electric drive. Polar door curtain do not have action component and do not produce noise during service. Cool strip has been designed from market experience and has been proved in independent tests to up to 50% of energy costs, while helping retail chill cabinets meet statutory temperature controls.

Polar grade PVC strip curtains are an option for Cold storage, Refrigerated doorways, Deli-Counters, Chiller Cabinets, Cold rooms and most retail refrigeration situations.

Package& Delivery of Polar PVC Strip Curtains

Wooden pallet,shirnk film,cartons and according to custom requires.

Colors of Polar PVC Strip Curtains

Polar door curtain are available in a range of colors, such like pale green, pale blue and clear. Blue is the most popular color in usages. If you used in the dark environment, just like cold rooms, clear color is the best choice for you.

Types of Polar PVC Strip Curtains

There are three styles of PVC strip curtain, Smooth, Single Ribbed and Double Ribbed. The door curtain used is dependent on the applications. PVC strips with raised ribbing on both sides are available offering improved durability enabling them to withstand repeated impact from heavy traffic such as forklift trucks.

- Q: What are the different types of plastic used in home appliances?

- Some common types of plastic used in home appliances include polypropylene, polystyrene, polyethylene, polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS).

- Q: Can plastic parts in home appliances be easily cleaned with specialized cleaning solutions?

- Yes, plastic parts in home appliances can generally be easily cleaned with specialized cleaning solutions. These solutions are designed to effectively remove dirt, grime, and stains without causing damage to the plastic surfaces. However, it is important to carefully read the instructions and ensure that the cleaning solution is suitable for the specific type of plastic used in the appliance.

- Q: How do plastic parts in microwaves handle exposure to electromagnetic waves?

- Plastic parts in microwaves are designed to handle exposure to electromagnetic waves. They are typically made from heat-resistant and microwave-safe materials that can withstand the high temperatures generated by the microwaves. These plastics are also formulated to be non-reactive and non-absorbent to the electromagnetic waves, ensuring safe and efficient heating of food without any adverse effects on the plastic components.

- Q: How do plastic home appliances compare in terms of recyclability rates?

- Plastic home appliances vary in terms of recyclability rates, as it depends on the type of plastic used and the availability of recycling facilities. While some appliances, like those made from easily recyclable plastics such as PET or HDPE, have higher recyclability rates, others made from more complex or mixed plastics might have lower rates. Additionally, the lack of proper recycling infrastructure can hinder overall recyclability rates. Therefore, it is important to consider the specific plastic used and the recycling capabilities in a particular area when assessing the recyclability of plastic home appliances.

- Q: How does the use of plastic in home appliances impact the overall lifespan of the appliance?

- The use of plastic in home appliances can impact the overall lifespan of the appliance in both positive and negative ways. On one hand, plastic components can contribute to lighter weight and increased portability of appliances, making them easier to handle and transport. Additionally, plastic is often more resistant to corrosion and rust, which can extend the lifespan of certain parts. However, plastic parts can be more prone to wear and tear, leading to a shorter overall lifespan compared to appliances with metal components. Additionally, the durability and quality of the plastic used can greatly influence the appliance's longevity.

- Q: How does the use of plastic in home appliances impact the overall user experience and convenience?

- The use of plastic in home appliances can positively impact the overall user experience and convenience. Plastic is a lightweight material, making appliances easier to handle, move, and install. It also offers durability, ensuring longer-lasting products that require less maintenance. Additionally, plastic often allows for sleek and modern designs, enhancing the aesthetic appeal of appliances. Moreover, plastic is non-conductive and resistant to corrosion, which enhances safety and reliability. However, excessive use of low-quality plastic can lead to decreased durability and potential environmental concerns. Thus, manufacturers must strike a balance between using plastic for convenience and ensuring sustainability.

- Q: What are the considerations for choosing the appropriate plastic texture for an appliance?

- When choosing the appropriate plastic texture for an appliance, several considerations need to be made. Firstly, the texture should be visually appealing and align with the overall design and aesthetics of the appliance. Secondly, it should have the necessary grip or tactile properties to ensure safe and comfortable handling. Additionally, the texture should be durable and resistant to wear and tear, as well as easy to clean. It is also important to consider the cost and feasibility of implementing the chosen texture in the manufacturing process. Overall, the chosen plastic texture should enhance the user experience and functionality of the appliance.

- Q: Can plastic home appliances be used in small spaces or apartments?

- Yes, plastic home appliances can be used in small spaces or apartments. Plastic appliances are generally lightweight and compact, making them ideal for limited spaces. Additionally, they are often designed to be portable and space-efficient, allowing them to fit comfortably in smaller areas without sacrificing functionality.

- Q: Are there any safety concerns with plastic parts in washing machines?

- Yes, there can be safety concerns with plastic parts in washing machines. Over time, plastic components such as control panels, door handles, or detergent dispensers can become brittle and prone to breakage. This can potentially lead to safety hazards, such as sharp edges or exposed electrical components. Additionally, certain types of plastic may release harmful chemicals when exposed to high temperatures, which can be a concern for both human health and the environment. Therefore, it is important for manufacturers to use durable and high-quality plastics in washing machine parts and for users to regularly inspect and maintain these components for any signs of damage.

- Q: How does the use of plastic in home appliances impact the overall aesthetics and design of the appliance?

- The use of plastic in home appliances can impact the overall aesthetics and design in various ways. Plastic often provides a sleek and modern appearance, allowing for smooth and clean lines in the design. It can be molded into different shapes and sizes, enabling manufacturers to create appliances with unique and innovative designs. Additionally, plastic can be found in a wide range of colors, offering flexibility in matching or contrasting with other elements in the home. However, excessive use of plastic might give appliances a cheaper or less durable feel, potentially affecting the perceived quality of the product.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Polar PVC Strips Curtains in Blue Color

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords