Welded Wire Mesh for Construction -1-1/4 X 1-1/4

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

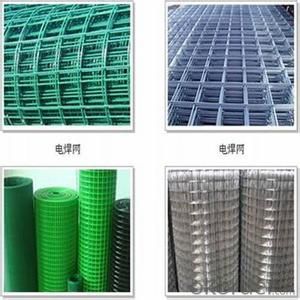

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the different mesh patterns available for steel wire mesh?

- There are several different mesh patterns available for steel wire mesh, each designed to serve specific purposes and applications. Some of the common mesh patterns include: 1. Square Mesh: This is the most basic and commonly used mesh pattern, consisting of wires woven in a simple crisscross pattern to form square openings. It is versatile and suitable for a wide range of applications, including fencing, screening, and filtration. 2. Rectangular Mesh: Similar to square mesh, but with rectangular openings instead. This pattern is often preferred when a more elongated opening is required, such as in architectural applications or for separation of materials based on size. 3. Dutch Weave Mesh: In this pattern, the warp wires are densely woven together while the weft wires are woven more openly. This creates a tight and strong mesh with finer openings, making it ideal for precision filtration, separation, and sieving applications. 4. Twilled Weave Mesh: Twilled weave mesh is characterized by diagonal patterns created by the weaving of wires. This pattern provides a higher degree of strength and durability compared to plain weave mesh, making it suitable for heavy-duty applications such as industrial screens and conveyor belts. 5. Welded Mesh: Unlike woven mesh patterns, welded mesh is made by welding intersecting wires together at their junctions. This results in a strong and rigid mesh with uniform openings, making it suitable for applications where high strength and rigidity are required, such as security fencing or reinforcement in concrete structures. 6. Expanded Metal Mesh: This pattern is created by simultaneously slitting and stretching a metal sheet, resulting in a mesh with diamond-shaped openings. Expanded metal mesh offers excellent strength-to-weight ratio, good ventilation, and anti-slip properties, making it suitable for walkways, platforms, and filtration applications. 7. Crimped Mesh: Crimped mesh is created by weaving wires with crimped or corrugated profiles, resulting in a mesh with a wavy pattern. This pattern provides better stability and increased rigidity compared to plain weave mesh, making it suitable for architectural applications, decorative purposes, and particle classification. These are just some of the common mesh patterns available for steel wire mesh. The choice of pattern depends on the specific requirements of the application, such as desired opening size, strength, rigidity, and aesthetics.

- Q: Can steel wire mesh be used for safety barriers and fencing?

- Yes, steel wire mesh can be used effectively for safety barriers and fencing. Its strong and durable composition makes it an ideal choice for providing security and preventing unauthorized access. The mesh design allows for visibility while still offering a reliable physical barrier. Additionally, steel wire mesh is resistant to corrosion, which ensures a long lifespan, making it a practical and cost-effective solution for safety barriers and fencing applications.

- Q: How does steel wire mesh perform in terms of resistance to weathering?

- Steel wire mesh performs well in terms of resistance to weathering. It is highly durable and can withstand various environmental conditions, including exposure to moisture, sunlight, and temperature fluctuations. This resistance to weathering ensures that the steel wire mesh remains structurally intact and maintains its strength and integrity over time, making it suitable for outdoor applications.

- Q: How does the temperature resistance affect the performance of steel wire mesh?

- The temperature resistance of steel wire mesh has a significant impact on its performance. Steel wire mesh is commonly used in various applications where it is exposed to different temperature conditions. Firstly, a higher temperature resistance of the steel wire mesh ensures that it can withstand extreme heat without losing its structural integrity. This is particularly important in industrial settings where the wire mesh may be exposed to high temperatures during manufacturing processes or in applications that involve heat transfer. If the wire mesh cannot withstand the temperature, it may deform, lose its shape, or even melt, rendering it useless and compromising the overall performance of the system it is being used in. Secondly, the temperature resistance of steel wire mesh also affects its mechanical properties. Steel wire mesh is often used for its strength and durability, and these properties can be affected by temperature changes. As the temperature increases, the strength of the wire mesh may decrease, leading to reduced load-bearing capacity. This can be critical in applications where the wire mesh is used for structural purposes or in situations where safety is a concern. In extreme cases, the wire mesh may fail completely, resulting in potential accidents or damage to the surrounding infrastructure. Moreover, the temperature resistance of steel wire mesh also influences its corrosion resistance. When exposed to high temperatures, the risk of oxidation and corrosion increases. If the wire mesh is not resistant to such corrosion, it can lead to rusting, weakening the structure and shortening its lifespan. Corrosion can also affect the appearance of the wire mesh, making it less visually appealing or suitable for certain applications. In conclusion, the temperature resistance of steel wire mesh plays a crucial role in determining its performance. A higher temperature resistance ensures that the wire mesh can withstand extreme heat without losing its structural integrity, maintains its mechanical properties, and prevents corrosion. It is essential to consider the temperature requirements of the application when selecting steel wire mesh to ensure optimal performance and longevity.

- Q: How does the installation method affect the overall performance of steel wire mesh?

- The installation method of steel wire mesh plays a crucial role in determining its overall performance. The way the mesh is installed can impact various aspects such as structural integrity, durability, and efficiency. Firstly, the installation method affects the structural integrity of the steel wire mesh. If the mesh is not properly installed, it may lead to weak points or gaps in the structure, compromising its strength and stability. A poorly installed mesh may result in sagging or deformation, which can reduce its overall performance and functionality. On the other hand, a correctly installed mesh ensures that it is tightly secured, maintaining its shape and enhancing its load-bearing capacity. Secondly, the installation method influences the durability of the steel wire mesh. Proper installation techniques ensure that the mesh is protected from external factors such as corrosion, weathering, or physical damage. For example, if the mesh is installed with appropriate spacing and firmly attached to its surrounding structure, it can resist external forces like wind, impacts, or vibrations, thus increasing its lifespan. Conversely, if the installation is subpar, it may lead to premature deterioration or failure of the mesh. Lastly, the installation method affects the efficiency of the steel wire mesh. A well-installed mesh can effectively perform its intended purpose, whether it is used for reinforcing concrete, providing security, or acting as a filtration system. The installation technique determines the proper alignment, tension, and positioning of the mesh, ensuring optimal functionality. On the other hand, an improper installation can result in reduced efficiency, such as compromised filtration capacity, decreased structural reinforcement, or inadequate security measures. In conclusion, the installation method significantly impacts the overall performance of steel wire mesh. A properly installed mesh ensures structural integrity, enhances durability, and maximizes efficiency. It is essential to employ skilled professionals and follow recommended installation guidelines to optimize the performance and longevity of steel wire mesh in various applications.

- Q: Can steel wire mesh be used for ceiling panels?

- Certainly, ceiling panels can indeed be constructed using steel wire mesh. This versatile material boasts a multitude of advantages when used for ceiling purposes. Not only does it lend a contemporary and industrial vibe to the ceiling, but it also facilitates proper air ventilation and circulation. With its robust and enduring nature, steel wire mesh proves to be ideal for areas with heavy foot traffic. Moreover, it effortlessly adapts to various ceiling sizes and shapes, allowing for easy customization. Additionally, steel wire mesh can be painted or coated to match any desired color or aesthetic, thereby enhancing the overall design of the space. In summary, steel wire mesh presents itself as a pragmatic and visually pleasing choice for ceiling panels.

- Q: What are the benefits of using steel wire mesh in the chemical manufacturing industry?

- There are several benefits of using steel wire mesh in the chemical manufacturing industry. Firstly, steel wire mesh provides excellent strength and durability. It can withstand high temperatures, corrosive chemicals, and extreme pressures, making it ideal for use in chemical manufacturing processes that involve harsh conditions. This ensures the safety and longevity of the equipment and infrastructure used in chemical plants. Secondly, steel wire mesh offers superior resistance to chemical reactions. It does not react with most chemicals, making it an excellent choice for containing and transporting corrosive substances. This reduces the risk of contamination and ensures the integrity of the manufacturing process. Furthermore, steel wire mesh provides excellent filtration capabilities. It can be woven to create a variety of mesh sizes, allowing for precise filtration of different chemical substances. This is crucial in maintaining product quality and purity, as well as preventing blockages in pipes and equipment. Additionally, steel wire mesh is highly versatile and can be customized to meet specific requirements. It can be fabricated into various shapes, sizes, and configurations to suit the unique needs of different chemical manufacturing processes. This flexibility enables the creation of efficient and effective systems for storing, separating, and handling chemicals. Moreover, steel wire mesh is relatively low maintenance compared to other materials. It is easy to clean and does not require frequent replacement, reducing downtime and overall operational costs. This makes it a cost-effective choice for the chemical manufacturing industry. Lastly, steel wire mesh is environmentally friendly. It can be recycled and reused, minimizing waste and contributing to sustainable practices. This aligns with the growing emphasis on sustainability and responsible manufacturing in the chemical industry. In conclusion, the benefits of using steel wire mesh in the chemical manufacturing industry include its strength and durability, resistance to chemical reactions, filtration capabilities, versatility, low maintenance requirements, and environmental friendliness. These advantages make steel wire mesh an invaluable material for ensuring the safety, efficiency, and sustainability of chemical manufacturing processes.

- Q: How is steel wire mesh used in geotechnical engineering?

- Steel wire mesh is commonly used in geotechnical engineering for various applications. One of the primary uses of steel wire mesh is in soil stabilization. When soil is weak or loose, it can lead to slope instability or erosion. Steel wire mesh is used to reinforce the soil and increase its strength and stability. It is typically installed horizontally or vertically in the ground to create a strong barrier that prevents soil movement and retains its shape. Steel wire mesh is also utilized in retaining walls and embankments. These structures are built to hold back soil or rock masses and prevent landslides or collapses. The mesh is installed within the soil or behind the retaining wall to reinforce it and provide additional strength. This helps to distribute the forces exerted by the soil or rock mass evenly, reducing the risk of failure. In addition, steel wire mesh is employed in erosion control systems. It is installed on slopes or riverbanks to protect the soil from erosion caused by water or wind. The mesh acts as a barrier, preventing the soil particles from being washed away or blown off. By stabilizing the soil and reducing erosion, steel wire mesh helps to maintain the integrity of the landscape and prevent environmental damage. Furthermore, steel wire mesh is used in geotechnical engineering for rockfall protection. In areas where there is a risk of rockfall, such as mountainous regions or along highways, steel wire mesh is installed to catch and contain falling rocks. The mesh is anchored to the slope or cliff face, creating a protective barrier that prevents rocks from reaching the ground and posing a hazard to people or structures below. Overall, steel wire mesh plays a crucial role in geotechnical engineering by providing reinforcement, stability, and protection to various structures and landscapes. Its versatility and durability make it a preferred choice for applications that require strength and resistance to environmental factors.

- Q: How is steel wire mesh used in reinforcement of waste treatment facilities?

- Due to its high tensile strength and durability, steel wire mesh is frequently utilized in waste treatment facilities to reinforce the structures that contain and store waste material. These facilities involve various processes, such as waste collection, sorting, and treatment, which generate a significant amount of waste material requiring storage or containment. The primary objective of employing steel wire mesh is to bolster the structural integrity and strength of the concrete used. During construction, the mesh is typically incorporated into the concrete mixture, forming a grid-like pattern that provides reinforcement throughout the structure. This reinforcement helps distribute and withstand the forces and pressures exerted by the waste material on the concrete walls, floors, and tanks. Moreover, steel wire mesh also serves to prevent cracking and enhance the overall durability of the concrete structures. Acting as a reinforcement layer, the mesh holds the concrete together, minimizing the risk of cracks and ensuring the structure remains intact over time. Additionally, steel wire mesh can be applied to reinforce concrete pipes and drainage systems in waste treatment facilities. These pipes and systems are essential for efficient waste and wastewater management and disposal. By reinforcing them with steel wire mesh, their strength and resistance to external forces are improved, enabling them to withstand the demands of waste treatment processes. In conclusion, steel wire mesh plays a crucial role in reinforcing waste treatment facilities, as it enhances the strength, durability, and structural integrity of the concrete structures. It provides a reliable solution for withstanding the forces and pressures exerted by waste materials, ensuring the long-term functionality and safety of these facilities.

- Q: Can steel wire mesh be used for privacy screens and partitions?

- Yes, steel wire mesh can be used for privacy screens and partitions. Steel wire mesh is a versatile material that offers both security and privacy. It can be used to create partitions and screens in various settings such as residential, commercial, and industrial spaces. The tightly woven pattern of the mesh provides a secure barrier while still allowing airflow and visibility. Additionally, steel wire mesh can be customized in terms of thickness, size, and design to meet specific privacy requirements. It is a durable and long-lasting option that can withstand harsh weather conditions and requires minimal maintenance. Overall, steel wire mesh is an excellent choice for privacy screens and partitions due to its strength, versatility, and aesthetic appeal.

Send your message to us

Welded Wire Mesh for Construction -1-1/4 X 1-1/4

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords