Mesh Wire Roll Concrete Reinforcement Mesh in Different Gauges

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Wire Roll Concrete Reinforcement Mesh in Different Gauges

1. Structure of Mesh Wire Roll Concrete Reinforcement Mesh Description:

Mesh Wire Roll Concrete Reinforcement Mesh is a welded wire fabric, prefabricated steel reinforcement material. The fabric is used to provide tensile strength and crack control to structural concrete elements. Smooth and trim mesh surface, solid and uniform structure and superior integral performance, it won't loosen even subject to local cutting or pressure, It has the characteristics of corrosion-resisting and oxidation-resisting.

All cross-points are welded together with strong electric resistance. With high precision, small error and high quality, Mesh Wire Roll Concrete Reinforcement Mesh is widely used in many sectors, ranging from the ordinary household to heavy industry. It is widely used in housing floor, roof, wall, terrace, concrete pavement, deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian, etc.

2. Main Features of Mesh Wire Roll Concrete Reinforcement Mesh:

• Durable

• Good Visual

• Convenient

• Widely-use

• Corrosion Resistance

• Sunshine Resistance

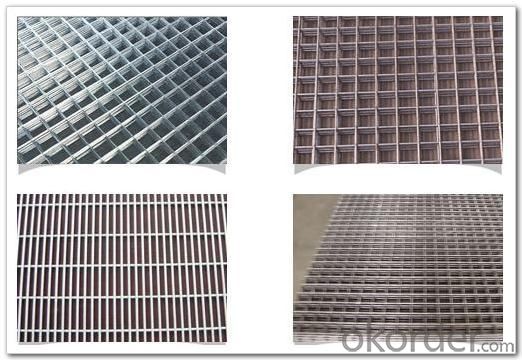

3. Mesh Wire Roll Concrete Reinforcement Mesh Images

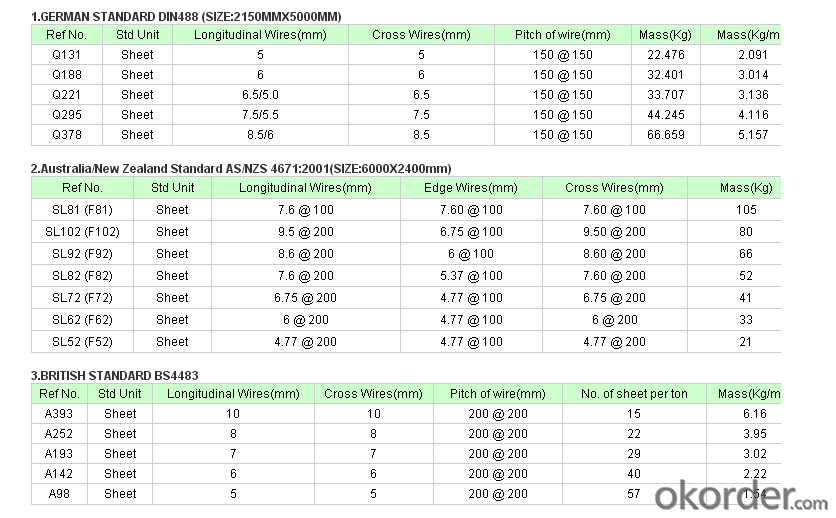

4. Mesh Wire Roll Concrete Reinforcement Mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire trading for more than ten years. We are specialized in export of various kinds of steel wire and wire mesh products, like Mesh Wire Roll Concrete Reinforcement Mesh we offer high quality steel wire; hot dipped wire; electro galvanized wire; PVC /PE coated wire; fencing , steel wire rope, steel wire strand, cable wire; wire mesh and other wire related products. Our factory covers an area of 14000 square meters and be capable of producing 10000 a day.

②What is Assortments of Mesh Wire Roll Concrete Reinforcement Mesh?

Welded Stainless Steel Wire Mesh Panels, Galvanized Welded Mesh Panels; Hot-dip Zinc Plating Welded Mesh Panels.

③How long can we receive the product after purchase?

In the purchase of Mesh Wire Roll Concrete Reinforcement Mesh within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Is steel wire mesh resistant to radiation?

- Yes, steel wire mesh is resistant to radiation. Steel is known for its high strength and durability, and it has the ability to block or attenuate various forms of radiation, including electromagnetic radiation and ionizing radiation. This makes steel wire mesh an effective material for shielding against radiation in various applications. Steel wire mesh with a higher density and smaller mesh size provides better radiation protection. However, it is important to note that the effectiveness of steel wire mesh in blocking radiation depends on the type and intensity of the radiation source.

- Q: What is the tensile strength of steel wire mesh?

- The tensile strength of steel wire mesh is determined by multiple factors, including the steel type, wire diameter, and manufacturing technique. Typically, steel wire mesh exhibits a substantial tensile strength, typically ranging from 50,000 to 150,000 pounds per square inch (PSI). Nevertheless, it is crucial to acknowledge that the precise tensile strength may fluctuate based on the particular type and grade of steel wire mesh employed. In order to obtain accurate specifications regarding the tensile strength of the steel wire mesh you are contemplating, it is advisable to consult the manufacturer or supplier.

- Q: Is steel wire mesh suitable for bridge construction?

- Bridge construction can indeed utilize steel wire mesh. Steel wire mesh is a material that is both versatile and durable, offering numerous advantages for bridge construction projects. To begin with, steel wire mesh possesses exceptional strength and load-bearing capacity, rendering it ideal for supporting heavy loads. This characteristic is of utmost importance in bridge construction, as bridges must endure the weight of various elements such as vehicles, pedestrians, and dynamic loads. Steel wire mesh provides the necessary structural integrity to guarantee the safety and stability of the bridge. Furthermore, steel wire mesh exhibits a high level of resistance against corrosion, a critical factor for bridges exposed to weather conditions and potentially corrosive substances like water, salt, and pollutants. The corrosion-resistant properties of steel wire mesh effectively extend the lifespan of the bridge and reduce maintenance costs. Moreover, steel wire mesh represents a cost-effective solution for bridge construction. It is easily obtainable and relatively simple to install, thereby reducing construction time and expenses. Additionally, steel wire mesh can be shaped and sized as needed, allowing for customization and adaptability to a variety of bridge designs and requirements. In conclusion, steel wire mesh proves to be an appropriate material for bridge construction due to its strength, load-bearing capacity, corrosion resistance, and cost-effectiveness. It supplies the essential structural support and durability necessary to ensure the longevity and safety of the bridge, making it a favored choice among engineers and construction professionals.

- Q: What are the different connection options for steel wire mesh panels?

- There are several different connection options available for steel wire mesh panels, depending on the specific application and requirements. Some of the common connection options include: 1. Welding: This is one of the most popular and widely used methods for connecting steel wire mesh panels. Welding involves melting the edges of the mesh panels and fusing them together using heat. This creates a strong and permanent connection. 2. Binding: Binding involves using wires or cables to secure the edges of the mesh panels together. This can be done by wrapping the binding material around the edges or using specialized binding clips or ties. Binding is a flexible and adjustable connection option that allows for easy disassembly if needed. 3. Clamping: Clamping involves using clamps or brackets to hold the edges of the mesh panels together. These clamps or brackets can be tightened or released as needed, allowing for easy installation and removal of the panels. Clamping is a versatile connection option that can be used for temporary or permanent installations. 4. Bolting: Bolting involves using bolts, nuts, and washers to secure the edges of the mesh panels together. This connection option provides a strong and durable connection, but it may require drilling holes in the panels and additional hardware. 5. Interlocking: Some steel wire mesh panels are designed with interlocking edges that fit together like puzzle pieces. This allows for easy and quick installation without the need for additional connection materials. Interlocking is a convenient and efficient connection option, but it may not be suitable for all applications. It is important to consider the specific needs and requirements of the project when choosing the connection option for steel wire mesh panels. Factors such as strength, durability, ease of installation, and disassembly should be taken into account to ensure a successful connection.

- Q: What are the benefits of using steel wire mesh in the chemical industry?

- There are several benefits of using steel wire mesh in the chemical industry: 1. Chemical Resistance: Steel wire mesh is highly resistant to various chemicals and corrosive substances. It can withstand exposure to acids, alkalis, solvents, and other aggressive chemicals commonly found in the chemical industry. This resistance ensures the longevity and durability of the mesh, even in harsh chemical environments. 2. Strength and Durability: Steel wire mesh has excellent strength and durability properties, making it suitable for heavy-duty applications in the chemical industry. It can withstand high temperatures, extreme pressures, and mechanical stresses, making it ideal for use in chemical reactors, storage tanks, and pipelines. 3. Filtration and Separation: Steel wire mesh can be woven into different mesh sizes and patterns, allowing for effective filtration and separation of solids and liquids. It can be used for various filtration processes, such as removing impurities, separating different components, and enhancing the purity of chemicals. The high porosity of the mesh ensures efficient flow rates and minimal pressure drops. 4. Safety and Protection: Steel wire mesh provides a protective barrier in the chemical industry, preventing accidental spills, leaks, or emissions of hazardous substances. It can be used as safety screens, containment enclosures, or protective covers for equipment and machinery. The robust nature of the mesh ensures reliable protection against chemical hazards. 5. Easy Maintenance and Cleaning: Steel wire mesh is easy to clean and maintain in the chemical industry. It can be easily washed, rinsed, or sterilized to remove any chemical residues or contaminants. This ease of maintenance ensures hygienic conditions and prevents cross-contamination between different chemicals or processes. 6. Cost-effectiveness: Steel wire mesh offers a cost-effective solution in the chemical industry. Its long lifespan, low maintenance requirements, and resistance to chemical degradation reduce the need for frequent replacements or repairs. Additionally, its versatility and adaptability make it a valuable investment for various applications, leading to overall cost savings. In summary, the benefits of using steel wire mesh in the chemical industry include chemical resistance, strength and durability, filtration and separation capabilities, safety and protection, easy maintenance and cleaning, and cost-effectiveness. These advantages make steel wire mesh a preferred choice for various critical processes and applications in the chemical industry.

- Q: What are the different sizes available for steel wire mesh?

- Steel wire mesh is available in various sizes, including commonly found options like 1/4 inch, 1/2 inch, and 1 inch, but can also be found in smaller or larger sizes depending on specific needs and applications.

- Q: Is steel wire mesh suitable for ceiling panels?

- Yes, steel wire mesh is suitable for ceiling panels. It is durable, strong, and has excellent structural integrity, making it an ideal choice for ceiling applications. Additionally, steel wire mesh offers good ventilation and can provide an aesthetically pleasing and modern look to the ceiling.

- Q: Can steel wire mesh be used for security purposes?

- Yes, steel wire mesh can be used for security purposes. It is commonly used in fencing and barriers to provide a strong and durable barrier that prevents unauthorized access and enhances security. The tightly woven structure of steel wire mesh makes it difficult to cut or breach, making it an effective option for securing properties, perimeters, and sensitive areas.

- Q: Is steel wire mesh easy to clean and maintain?

- Steel wire mesh is relatively easy to clean and maintain due to its smooth surface. One can effortlessly eliminate dirt, dust, and other debris using a soft brush, vacuum cleaner, or even a hose. Moreover, steel wire mesh is resistant to corrosion, making it capable of enduring cleaning agents, water, and other substances without degradation. This resistance facilitates easier maintenance and helps keep it in good condition. However, it is important to consider that wire mesh with a coating or paint may require more delicate cleaning methods to prevent damage to the finish. In summary, steel wire mesh is a robust and low-maintenance material that can be cleaned and maintained effortlessly.

- Q: Can steel wire mesh be used in automotive applications?

- Yes, steel wire mesh can be used in automotive applications. Steel wire mesh is commonly used in automotive manufacturing for various purposes such as reinforcing vehicle body structures, providing protection for radiators and other components, as well as for interior applications like seat frames and headrests. It offers excellent strength, durability, and resistance to impact, making it a suitable material for automotive applications where safety and reliability are crucial. Additionally, steel wire mesh can be easily molded and shaped to fit different automotive parts, providing flexibility in design and assembly.

Send your message to us

Mesh Wire Roll Concrete Reinforcement Mesh in Different Gauges

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords