Welded wire mesh-1/4 X 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

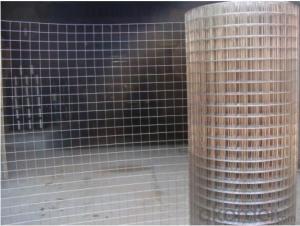

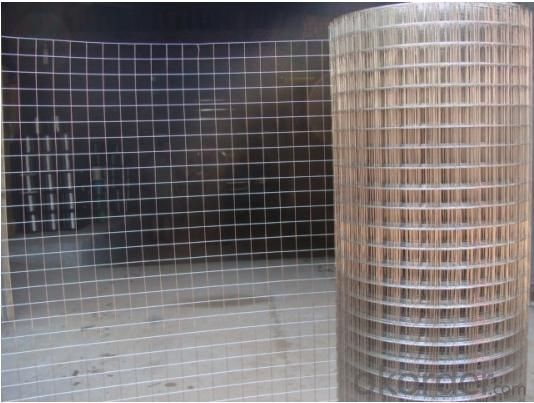

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How is steel wire mesh used in security systems?

- Steel wire mesh is commonly used in security systems due to its durability and strength. It is often used to create fences, barriers, and enclosures that provide a high level of security. The tightly woven mesh design makes it difficult for intruders to penetrate or climb over, acting as a physical deterrent. In security systems, steel wire mesh is typically installed to protect sensitive areas such as airports, government buildings, prisons, and industrial facilities. It can be used to secure perimeters, windows, doors, and even rooftops. The mesh can be customized to fit specific requirements, allowing for flexibility in design and installation. Steel wire mesh also offers excellent visibility, allowing security personnel to monitor the surroundings more effectively. It does not obstruct views or compromise natural lighting, ensuring a clear line of sight. Additionally, the mesh can be integrated with other security components such as surveillance cameras, motion sensors, and alarms to create a comprehensive security system. One of the key advantages of steel wire mesh in security systems is its resistance to cutting and tampering. The strong and rigid nature of the steel wires makes it extremely difficult to manipulate or break through. This makes it an effective deterrent against forced entry or vandalism. Moreover, steel wire mesh is highly resistant to corrosion and weathering, making it suitable for both indoor and outdoor security applications. It can withstand harsh environmental conditions, including extreme temperatures, heavy rain, and UV exposure, without deteriorating or losing its effectiveness. Overall, steel wire mesh is a versatile and reliable component in security systems. Its strength, durability, visibility, and resistance to tampering make it an ideal choice for enhancing security and protecting valuable assets.

- Q: How does steel wire mesh perform in terms of fire resistance?

- Steel wire mesh performs well in terms of fire resistance. Due to its material composition, steel wire mesh is inherently non-combustible and is able to withstand high temperatures without melting or igniting. This makes it highly effective in preventing the spread of fire and providing a barrier against flames and heat. Additionally, the open structure of the mesh allows for better ventilation and heat dissipation, further enhancing its fire resistance capabilities. Steel wire mesh is commonly used in applications where fire safety is a concern, such as in construction, industrial settings, and for fire-rated enclosures.

- Q: Can steel wire mesh be used for reinforcement?

- Yes, steel wire mesh can be used for reinforcement in various applications such as concrete structures, masonry walls, and even in the reinforcement of soil for stabilization purposes. It provides additional strength, improves structural integrity, and helps prevent cracking or failure under load.

- Q: How is steel wire mesh used in reinforcement of security projects?

- Steel wire mesh is commonly used in the reinforcement of security projects due to its strength, durability, and versatility. It is a popular choice for securing areas such as fences, gates, and windows, as well as for creating barriers and enclosures. One of the main ways steel wire mesh is used in security projects is as a barrier to prevent unauthorized access. It can be installed on fences and gates to create a physical barrier that is difficult to breach. The tight interlocking pattern of the wire mesh makes it difficult for intruders to cut or climb over, providing a high level of security. Steel wire mesh is also used to reinforce windows and doors, particularly in high-security buildings or areas prone to break-ins. The mesh is typically installed behind the glass, acting as a protective layer that prevents forced entry. It can withstand significant impact and force, making it an effective deterrent against burglaries and vandalism. Moreover, steel wire mesh is commonly used to create enclosures and cages for securing valuable items or sensitive equipment. It can be used to construct secure storage areas, cages for holding prisoners or detainees, or enclosures for protecting machinery and assets. The strength and rigidity of the mesh provide a reliable and durable solution for securing these areas. Additionally, steel wire mesh is often used in the reinforcement of perimeter security projects such as airports, military installations, and government facilities. It can be installed along the perimeter fence or wall to provide an additional layer of security. The mesh acts as a deterrent and can help to detect and prevent unauthorized access or intrusion. In summary, steel wire mesh plays a crucial role in the reinforcement of security projects. Its strength, durability, and versatility make it an ideal choice for securing areas such as fences, gates, windows, and enclosures. Whether used as a barrier, reinforcement for windows and doors, or in perimeter security, steel wire mesh provides a reliable and effective solution for enhancing security measures.

- Q: How is steel wire mesh used in the mining industry?

- Steel wire mesh is widely used in the mining industry for a variety of applications. One of the primary uses of steel wire mesh in mining is for safety purposes. It is commonly used to create barriers and fences around mine shafts, open pits, and other hazardous areas to prevent unauthorized access and protect workers from potential accidents. In addition to safety, steel wire mesh is also utilized for sieving and filtering purposes in the mining industry. It is commonly used as a screen or sieve to separate and classify different sizes of minerals, rocks, and ores during the mining process. This helps in the efficient extraction and processing of materials, ensuring that only the desired particles are collected and further processed. Furthermore, steel wire mesh is used in mining for reinforcement and support purposes. It is often installed as a mesh lining in tunnels, underground mines, and other excavations to provide structural stability and prevent the collapse of surrounding rocks and soil. This reinforcement helps to maintain the integrity of the mining infrastructure and ensures the safety of workers and equipment. Moreover, steel wire mesh is also utilized for ventilation purposes in the mining industry. It is installed as ventilation screens or ducting covers to allow the flow of fresh air into underground mines and remove harmful gases and dust. Proper ventilation is crucial for maintaining a safe and healthy working environment for miners. Overall, steel wire mesh plays a vital role in the mining industry by providing safety barriers, facilitating sieving and filtering, reinforcing structures, and enabling proper ventilation. Its versatility, strength, and durability make it an indispensable material in various mining applications, helping to enhance efficiency, productivity, and safety in mining operations.

- Q: Can steel wire mesh be used in high-temperature environments?

- Yes, steel wire mesh can be used in high-temperature environments. Steel wire mesh is known for its strength and durability, making it suitable for applications in extreme conditions. However, it is important to consider the specific temperature range and choose a type of steel wire mesh that is resistant to heat and corrosion.

- Q: What are the safety precautions for handling steel wire mesh?

- When handling steel wire mesh, there are a few important safety precautions to keep in mind. Firstly, it is essential to wear appropriate personal protective equipment, such as gloves and safety glasses, to prevent any injuries or cuts from the sharp edges of the mesh. Secondly, ensure that the work area is well-lit and free from any obstructions or tripping hazards. It is also advisable to use proper lifting techniques and equipment when moving or lifting heavy rolls or sheets of wire mesh to avoid strains or back injuries. Lastly, be cautious when working with power tools or machinery to avoid accidental contact with the mesh, and always follow the manufacturer's instructions and guidelines for safe operation.

- Q: Is steel wire mesh suitable for concrete reinforcement?

- Steel wire mesh is an ideal choice for reinforcing concrete. Known also as welded wire mesh or rebar mesh, this material is commonly used in concrete structures to enhance their strength and stability. The mesh consists of steel wires arranged in a grid pattern, which effectively distributes tensile forces throughout the concrete, preventing cracks and improving its durability. By incorporating steel wire mesh into the concrete mix, the compressive strength of the concrete is further reinforced, addressing its inherent weakness in tension. This is particularly crucial in applications like slabs, walls, and foundations where the concrete needs to withstand bending and flexing forces. The benefits of steel wire mesh for concrete reinforcement are manifold. Firstly, it enhances the structural integrity of the concrete by bolstering its tensile strength. This is especially important in scenarios where the concrete is subjected to bending and flexing forces. Secondly, the presence of steel wire mesh helps control cracking in the concrete. As the concrete undergoes curing and shrinkage, the mesh acts as a reinforcement, reducing the likelihood of large cracks forming. Any cracks that do occur tend to be smaller and more manageable. Moreover, the installation of steel wire mesh is relatively straightforward. It is available in rolls or sheets that can be easily cut and shaped to fit the desired dimensions. It can be placed within the concrete formwork before pouring, ensuring its proper integration within the structure. However, it is crucial to select the appropriate size and spacing of the wire mesh based on the specific application and design requirements. Different projects may necessitate different wire mesh sizes and configurations. Therefore, consulting a qualified engineer or adhering to relevant building codes and standards is essential to ensure the correct selection and installation of steel wire mesh for concrete reinforcement.

- Q: Can steel wire mesh be used for creating insect screens or window grilles?

- Yes, steel wire mesh can be used for creating insect screens or window grilles. Steel wire mesh is a durable and strong material that can effectively prevent insects from entering through windows or doors. It is commonly used for creating insect screens that are placed over windows or doors to allow for fresh air flow while keeping insects out. Steel wire mesh can also be used for creating window grilles, which provide additional security to windows while still allowing for visibility and ventilation. The strength and resilience of steel wire mesh make it an ideal choice for protecting against insects and securing windows and doors.

- Q: Can steel wire mesh be used for erosion control?

- Yes, steel wire mesh can be used for erosion control. It is commonly used in various erosion control applications such as retaining walls, slope stabilization, and shoreline protection. The mesh acts as a barrier that helps prevent soil erosion and provides stability to the affected area.

Send your message to us

Welded wire mesh-1/4 X 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords